Reinforcing construction method of cylindrical frame column template

A formwork reinforcement and construction method technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc. The effect of formwork turnover, reducing the difficulty of reinforcement, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of cylindrical frame column template reinforcement construction method of the present embodiment, its steps are:

[0033] Step 1: First, familiarize yourself with the drawings to determine the cylindrical construction column;

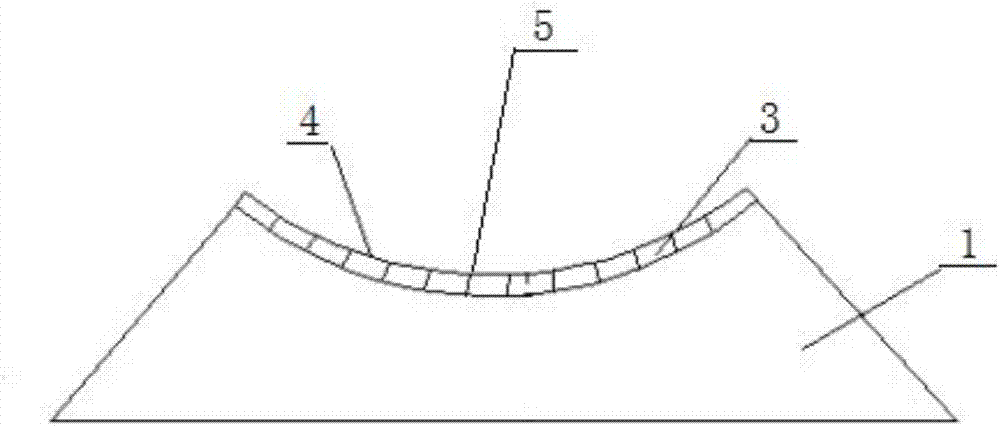

[0034] Step 2: Make the support keel 1 on this basis, which is made of two layers of plywood 2 sandwiching short square wood 3;

[0035] Step 3: Make the arc-shaped die groove 5 formed by the thin plank 4 and the short square wood 3 again;

[0036] Step 4: Use several square logs, lay them on the supporting keel 1 for fixing, and lay thin wood boards 4 on the upper layer as the contact material of the cylindrical column concrete surface;

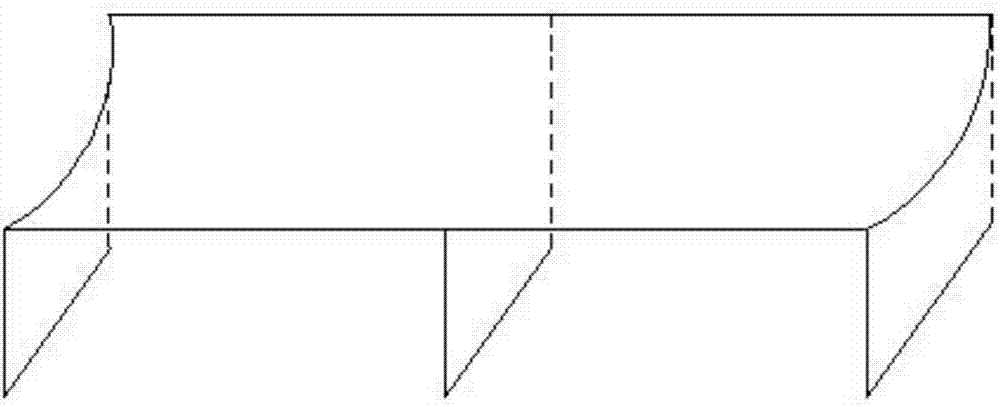

[0037] Step 5: Then assemble and reinforce the cylinder module 7 composed of the support keel 1 and the arc-shaped mold groove 5. A total of four cylinder modules 7 are assembled and reinforced. The distance between the support keel 1 in the cylinder module 7 is 1000mm. The distance between the pulling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com