Construction structure and method of ultrahigh spatial stiff beam cladding reinforced concrete

A technology of reinforced concrete and stiff beams, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of difficult construction, heavy workload, long construction period, etc., and achieve fast erection , easy operation, and the effect of reducing the cost of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

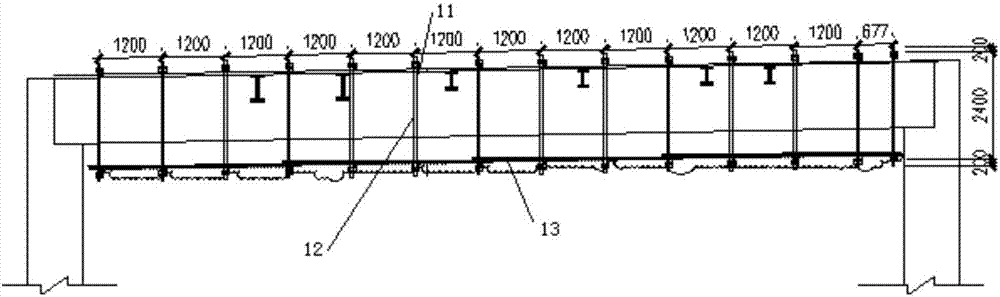

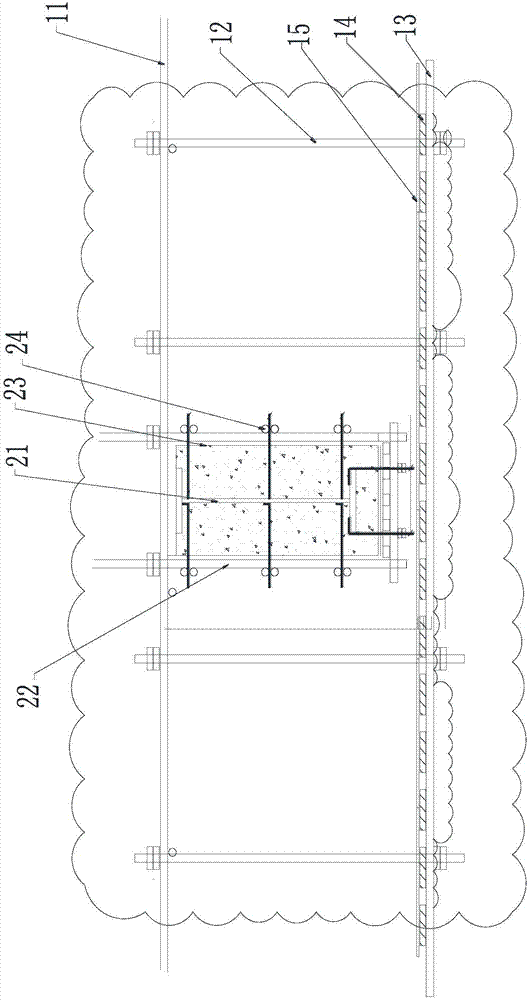

[0031] like Figure 1-2 As shown, this embodiment relates to a construction structure in which reinforced concrete is covered with rigid beams in a super-high space. Roof beams are arranged on the top of the super-high space. Specifically, the construction structure includes a suspended operating platform and a Stiff beam structure above; the suspended operation platform includes the upper horizontal bar 11, the lower horizontal bar 13, the boom 12, the scaffolding board 14 and the plywood 15; Above, the suspender 12 is arranged between the upper horizontal rod 11 and the lower horizontal rod 13, the lower horizontal rod 13 is covered with scaffold boards 14, and the scaffold board 14 is covered with plywood 15; the stiff beam structure includes steel beams 21, buckles Piece-type hanger 22, steel bars, formwork 23; steel beam 21 is set on the top of the super-high space and is located in the fastener-type hanger 22, the fastener-type hanger 22 is fixed on the roof beam, and th...

Embodiment 2

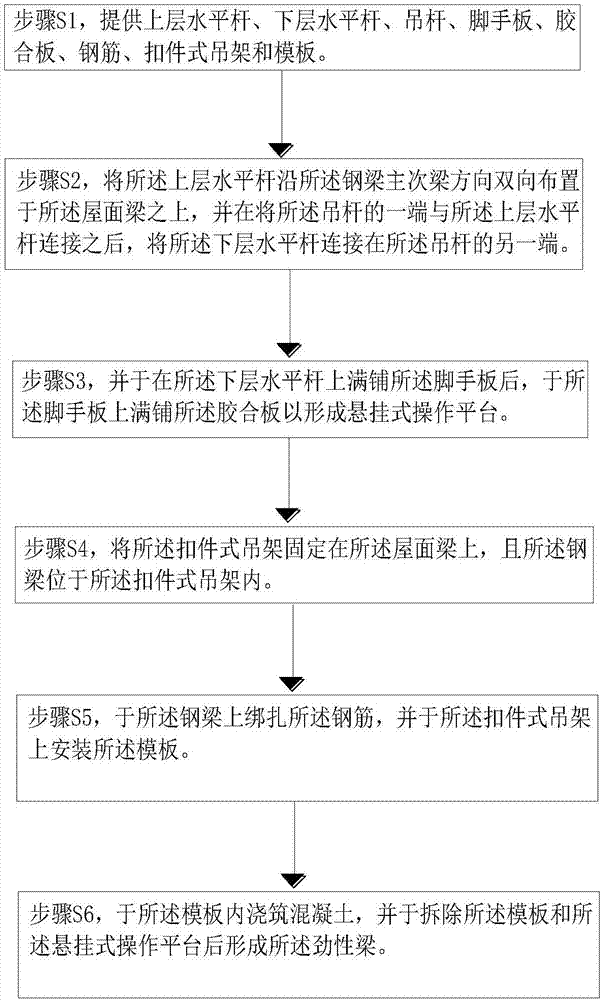

[0049] like image 3 As shown, this embodiment discloses a construction method for super-high space stiffened beams wrapped with reinforced concrete. Roof beams and steel beams are arranged on the top of the super-high space. Specifically, the method includes the following steps:

[0050] Step S1, providing the upper horizontal bar, the lower horizontal bar, the suspender, the scaffold board, the plywood, the steel bar, the fastener type hanger and the formwork.

[0051] Step S2, arrange the upper level horizontal bar on the roof beam along the direction of the main and secondary beams of the steel beam in both directions, and after connecting one end of the suspender to the upper level horizontal bar, connect the lower level horizontal bar to the other end of the suspender, and then A safety net is laid under the lower horizontal bar.

[0052] Preferably, both ends of the suspender are provided with double anti-slip fasteners, and the suspender is respectively connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com