Sponge city drainage structure and sponge city water circulation method

A technology of drainage structure and sponge city, applied in drainage structures, sewage removal, chemical instruments and methods, etc., can solve problems such as unfavorable urban drainage system operation, inability to connect water collection wells and drainage wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

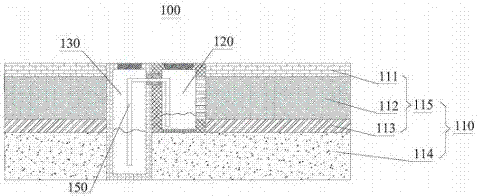

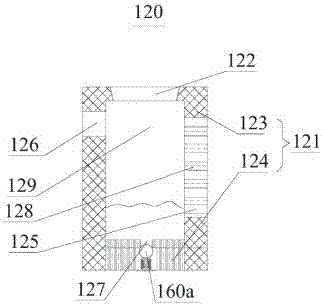

[0027] figure 1 A schematic structural diagram of a drainage structure 100 suitable for a sponge city provided in this embodiment. see figure 1 , in this embodiment, the drainage structure 100 includes a road layer structure 110 , a water collection well 120 and a drainage well 130 .

[0028] read on figure 1 , in this embodiment, the road layer structure 110 includes a permeable part 115 and a soil layer 114 from top to bottom, and the permeable part 115 includes a color permeable concrete layer 111, a high-permeability concrete layer 112 and a gravel grade from top to bottom. Layer 113. The colored permeable concrete layer 111 can not only satisfy people's desire for color and cultural atmosphere, but also has a beautiful appearance and appreciation; at the same time, it is conducive to the infiltration of surface water, improves the air permeability and water permeability of the surface, and has the function of regulating the temperature and humidity of the urban surface...

Embodiment 2

[0045] This embodiment provides a drainage structure 100 suitable for sponge cities. This embodiment is an improvement made on the basis of the technical solution in Example 1. The technical solution described in Example 1 is also applicable to this embodiment. 1 The disclosed technical solutions will not be described repeatedly. The difference between this embodiment and Embodiment 1 lies in the structure of the one-way valve 160b in this embodiment.

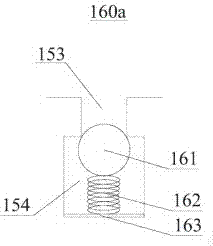

[0046] Figure 5 A structural schematic diagram of the one-way valve 160b in the drainage structure 100 suitable for the sponge city provided by this embodiment. read on Figure 5 , in this embodiment, the cross-sections of the upper opening 153 and the lower opening 154 are both rectangular, the spool 161 is a rectangular spool 261 , and the rectangular spool 261 is set at the junction of the upper opening 153 and the lower opening 154 . The cross-sectional area of the upper opening 153 is smaller than the cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com