Abrasion-resistant white glaze, wearproof white glaze ceramics prepared through white glaze, and preparing method of wearproof white glaze ceramics

A technology for ceramic products and wear-resistant white glaze, applied in the field of ceramics, can solve the problems of complicated preparation process, inability to obtain white glaze ceramic products, increase cost, etc., and achieve the effects of increasing refractive index, improving high temperature fluidity, and beautiful glaze surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

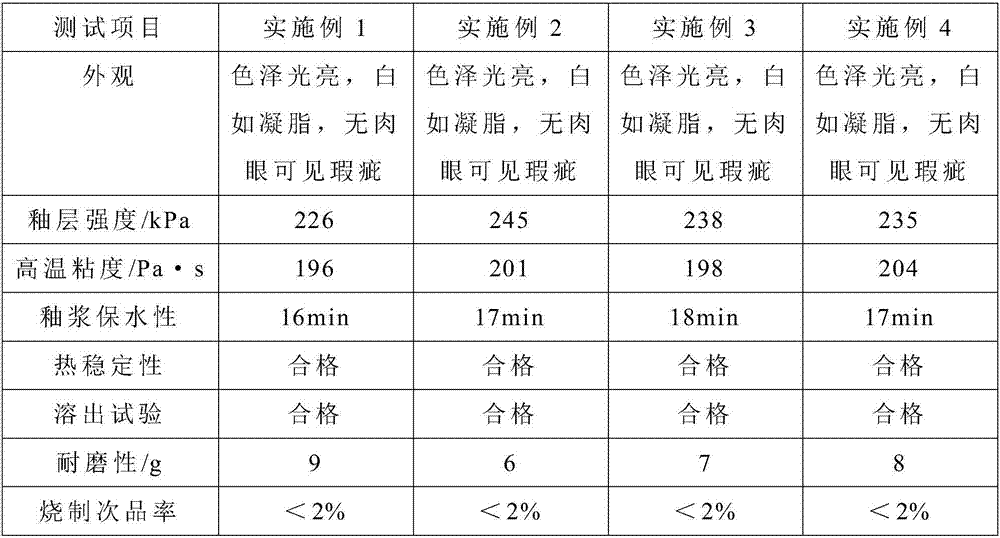

Examples

Embodiment 1

[0024] A wear-resistant white glaze with a melting temperature of 800°C±5°C and a flow glaze at 1200°C, specifically comprising the following raw materials in parts by mass: 35 parts of feldspar, 20 parts of calcium oxide, 5 parts of quartz, and water glass 2 parts, 3 parts of kaolin, 2 parts of zinc oxide, 2 parts of barium carbonate, 5 parts of heavy calcium carbonate.

[0025] The method for preparing wear-resistant white glaze ceramic products with the wear-resistant white glaze comprises the following steps:

[0026] 1) Weigh each raw material component according to the formula and add it to a fast ball mill, and perform wet ball milling for 12 hours, wherein the material: ball: water ratio is 1:3:0.8;

[0027] 2) Pass the ground glaze water through a 180-mesh sieve, add water to the filtrate to make a glaze water with a concentration of 41 degrees Baume;

[0028] 3) bisque firing the molded ceramic green body at 800°C for 8 hours, and then cooling naturally;

[0029] 4...

Embodiment 2

[0032] A wear-resistant white glaze with a melting temperature of 800°C±5°C and a flow glaze at 1200°C, specifically comprising the following raw materials in parts by mass: 40 parts of feldspar, 24 parts of calcium oxide, 12 parts of quartz, water glass 4 parts, 5 parts of kaolin, 3 parts of zinc oxide, 4 parts of barium carbonate, 7 parts of heavy calcium carbonate, 12 parts of waste porcelain powder, and 8 parts of silicon carbide.

[0033] The method for preparing wear-resistant white glaze ceramic products with the wear-resistant white glaze comprises the following steps:

[0034] 1) Weigh each raw material component according to the formula and add it to a fast ball mill, and perform wet ball milling for 14 hours, wherein the material: ball: water ratio is 1:3:0.8;

[0035] 2) Pass the ground glaze water through a 180-mesh sieve, and add water to the filtrate to make a glaze water with a concentration of 43 degrees Baume;

[0036] 3) bisque firing the molded ceramic gre...

Embodiment 3

[0040] A wear-resistant white glaze with a melting temperature of 800°C±5°C and a flow glaze at 1200°C, specifically comprising the following raw materials in parts by mass: 42 parts of feldspar, 26 parts of calcium oxide, 10 parts of quartz, water glass 5 parts, 6 parts of kaolin, 4 parts of zinc oxide, 4 parts of barium carbonate, 8 parts of heavy calcium carbonate, 12 parts of waste porcelain powder, and 6 parts of silicon carbide.

[0041] The method for preparing wear-resistant white glaze ceramic products with the wear-resistant white glaze comprises the following steps:

[0042] 1) Weigh each raw material component according to the formula and add it to a fast ball mill, and perform wet ball milling for 16 hours, wherein the material: ball: water ratio is 1:3:0.8;

[0043] 2) Pass the ground glaze water through a 180-mesh sieve, add water to the filtrate to make a glaze water with a concentration of 44 degrees Baume;

[0044] 3) Biscuit firing the molded ceramic green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com