Hopper installing structure of bucket elevator

A bucket elevator and installation structure technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of large force between the hopper and the material, hopper deformation, damage, etc., to ensure the normal operation process, improve the service life, and avoid The effect of damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

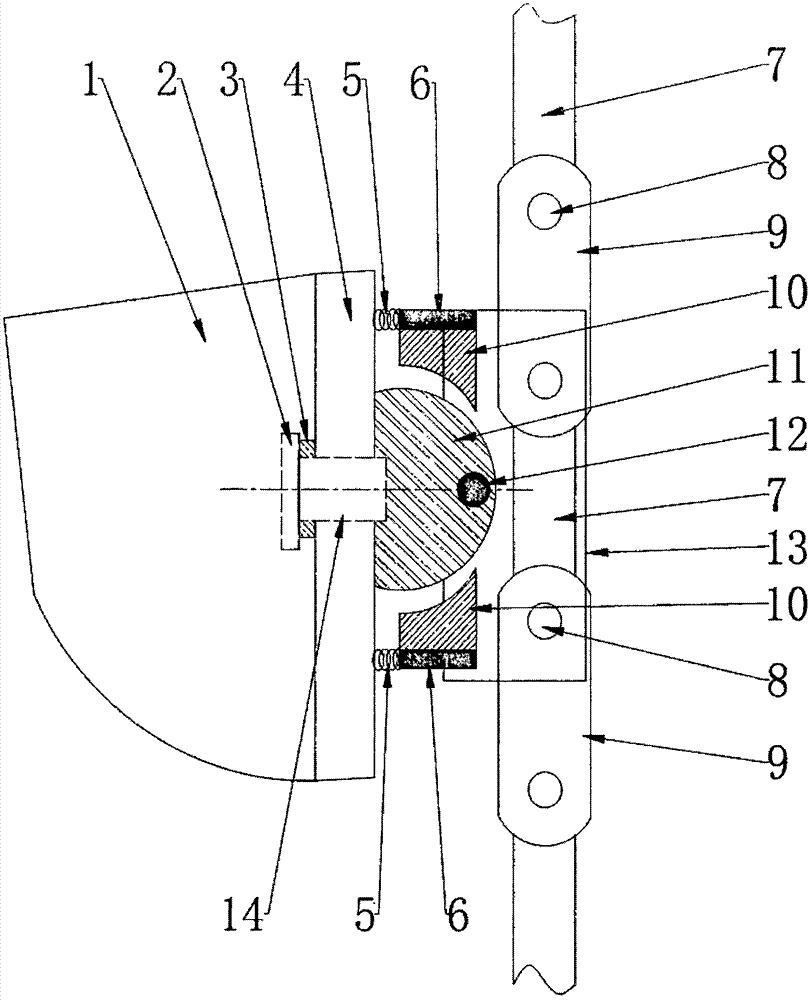

[0016] like figure 1 Shown: a hopper installation structure of a bucket elevator, the hopper installation structure is installed on the transmission chain of the bucket elevator through the installation block 13, and the transmission chain is composed of an inner chain plate 7 and an outer chain plate 9 connected end-to-end through the chain shaft 8 The upper end and the lower end of the mounting block 13 are respectively fixedly installed on two chain shafts 8 ends of the same inner chain plate 7 two ends; the left side of the mounting block 13 is the hopper 1, and the right part of the hopper 1 is a vertical side plate 4 , the side plate 4 is provided with a horizontal fixed rod 14, the left end of the fixed rod 14 is the cap body 2, the right end of the fixed rod 14 is provided with an arc-shaped plate 11, and the right part of the arc-shaped plate 11 is connected to the mounting block 13 by the hinge shaft 12 The left part of the hinge is hinged; the gasket 3 is sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com