Flour bagging device

A bagging device, flour technology, applied in the direction of packaging, transportation and packaging, types of packaged items, etc., can solve a large number, continuous, adverse effects on the health of operators, increased air pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

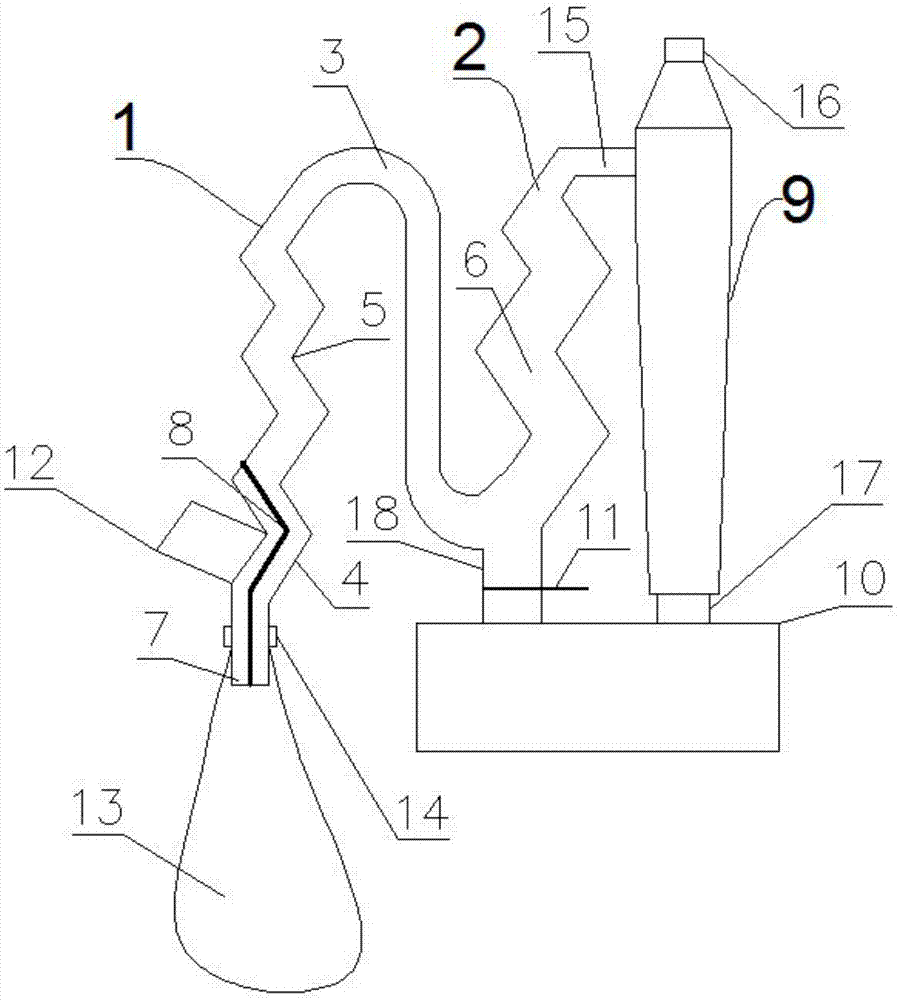

[0015] Such as figure 1 As shown, a flour bagging device includes a cyclone separator 13, a first separation pipeline 1, a second separation pipeline 2 and a drop tube between the first separation pipeline 1 and the second separation pipeline 2 Road 3, the cyclone separator 13 includes an inlet port 15, an air outlet port 16 and a solid material outlet port 17, and the first separation pipeline 1, the blanking pipeline 3 and the second separation pipeline 2 are all vertically arranged;

[0016] The first separation pipeline 1 is composed of a V-shaped pipeline 4 with the opening facing the left at the lower part and a W-shaped pipeline 5 with the opening facing the left at the upper part; the blanking pipeline 3 is S-shaped; the second separation pipe Road 2 is mainly composed of W-shaped pipeline 2 6 with the opening facing left;

[0017] The lower end of the first separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com