Self-locking rope tow hook device

A technology of self-locking device and trailer hook, applied in vehicle parts, transportation and packaging, towing connectors, etc., can solve problems such as difficulty, tow rope breakage, troublesome tow rope removal, etc., to achieve fast response time and strong braking effect. , The effect of reducing the damage rate of the tow rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

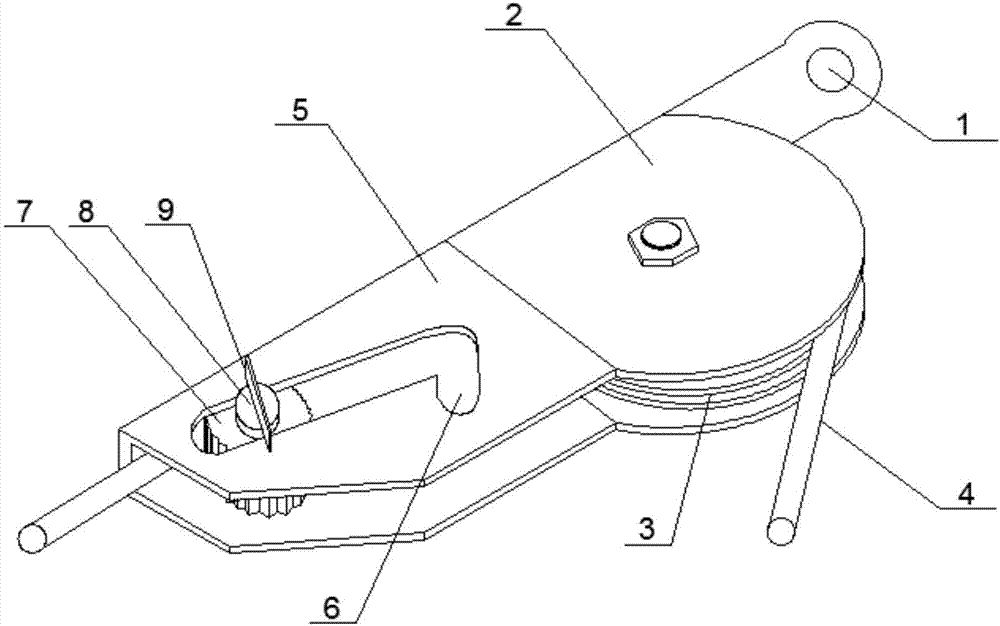

[0014] The present invention is a self-locking rope trailer hook device, which includes a runner 3 and its support frame 2, the support frame 2 is connected with a self-locking device, and one end of a steel wire rope 4 is wound around the self-locking device after passing through the self-locking device On the runner 3, the key point is that the self-locking device includes a U-shaped fixed plate 5 and a roller 7. The U-shaped fixed plate 5 includes upper and lower side plates, and a pair of L-shaped slot holes are opened at the same position of the side plates. 6. The axle center of the roller 7 is provided with a wheel shaft 8, and the two ends of the wheel shaft 8 form a sliding fit structure with the L-shaped slot 6, and the length direction of the L-shaped slot 6 is aligned with the U of the U-shaped fixing plate 5. The included angle between the bottoms of the grooves is an acute angle, and the roller 7 is provided with gear teeth, and the minimum gap between the teeth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com