Clamping tool for crystal cutting

A crystal cutting and clamping technology, applied in the direction of fine work equipment, work accessories, manufacturing tools, etc., can solve the problems of small contact area of screws, unstable processing process, and large number of screws, etc., to achieve large clamping area, Ensure smoothness and center balance, fast clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

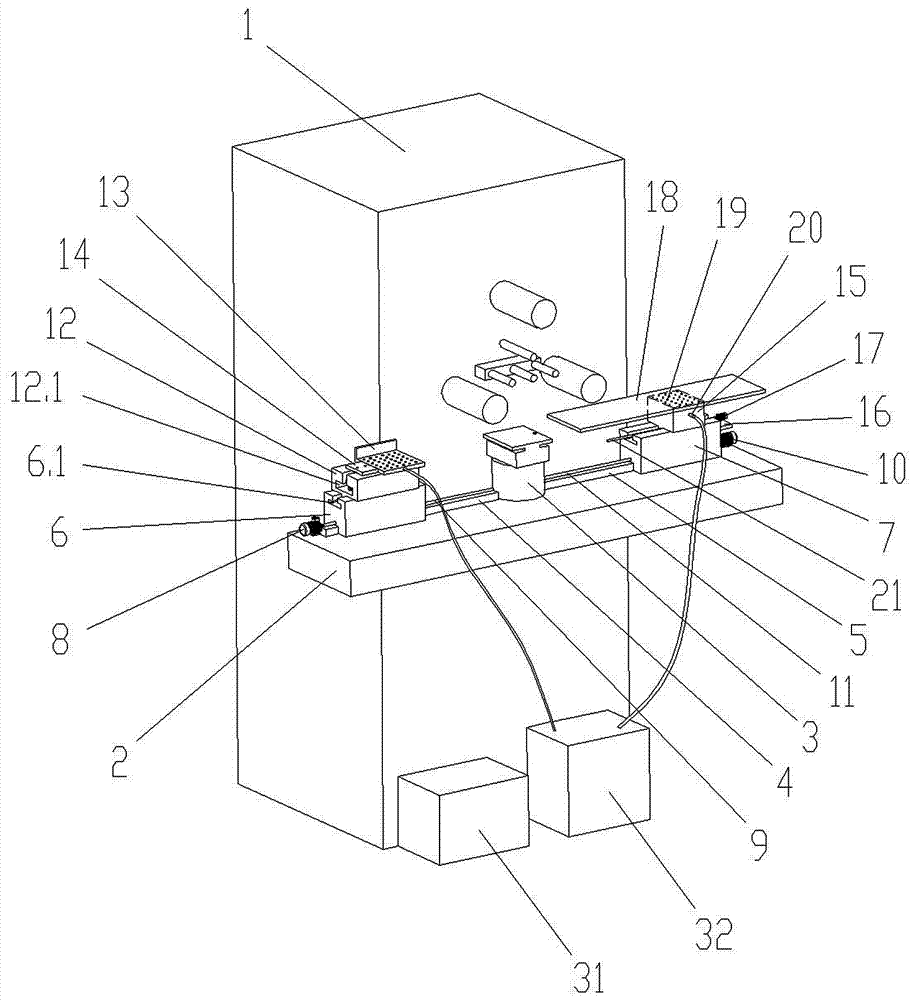

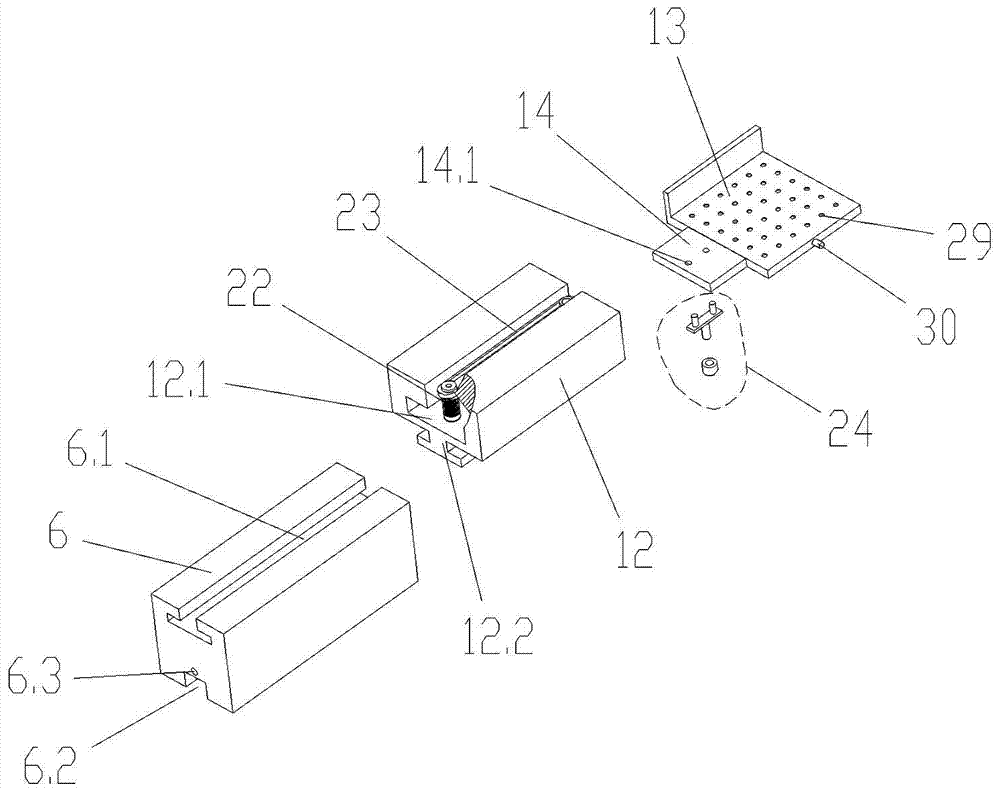

[0019] Such as figure 1 and figure 2 As shown, a clamping tool for crystal cutting provided by the present invention includes a square bottom plate 1. When in use, the bottom plate 1 is installed on the fixing seat of the cutting machine, and a circle is arranged at the center of the upper side of the bottom plate 1 Shaped grooves, in the grooves are fixedly connected to the fixed cylinder 2 by adhesive bonding.

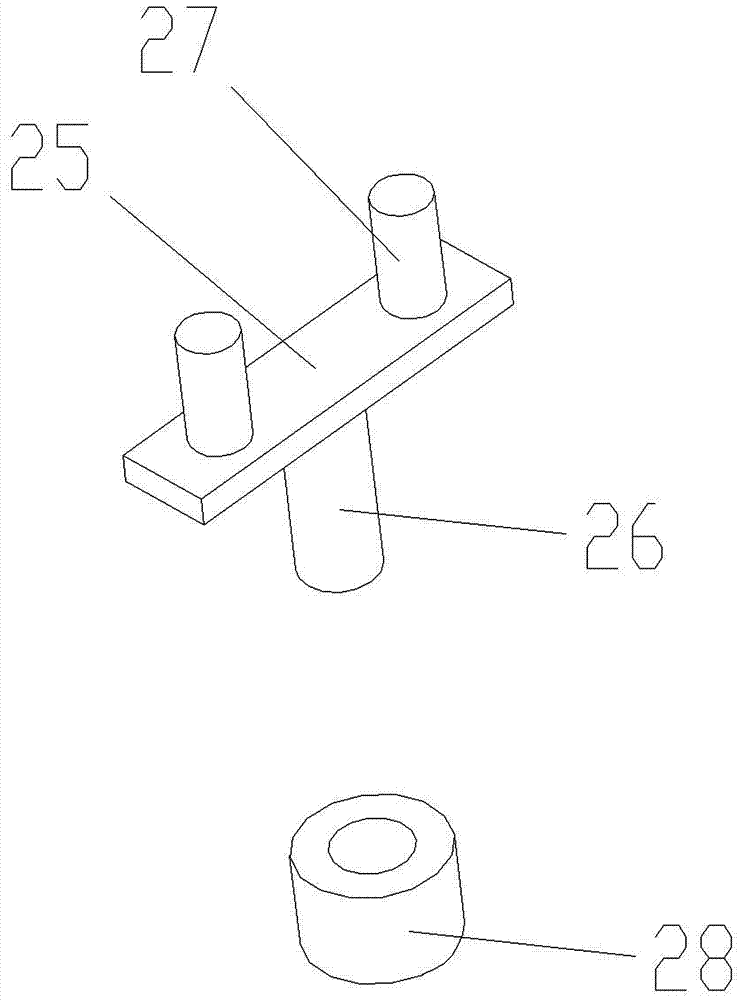

[0020] The fixed cylinder 2 is a circular bobbin structure, three open slots 3 are evenly distributed on the upper side of the fixed cylinder 2, and a plug-in plate 6 is snapped into e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com