Oil and gas pipeline burst detecting and positioning method

A technology of oil and gas pipelines and positioning methods, applied in pipeline systems, through detection of fluid appearance at leak points, measurement devices, etc., can solve the problem of complex pipeline wiring structure, many personnel required for operation, and difficult to solve the problem of signal recording and transmission clock synchronization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

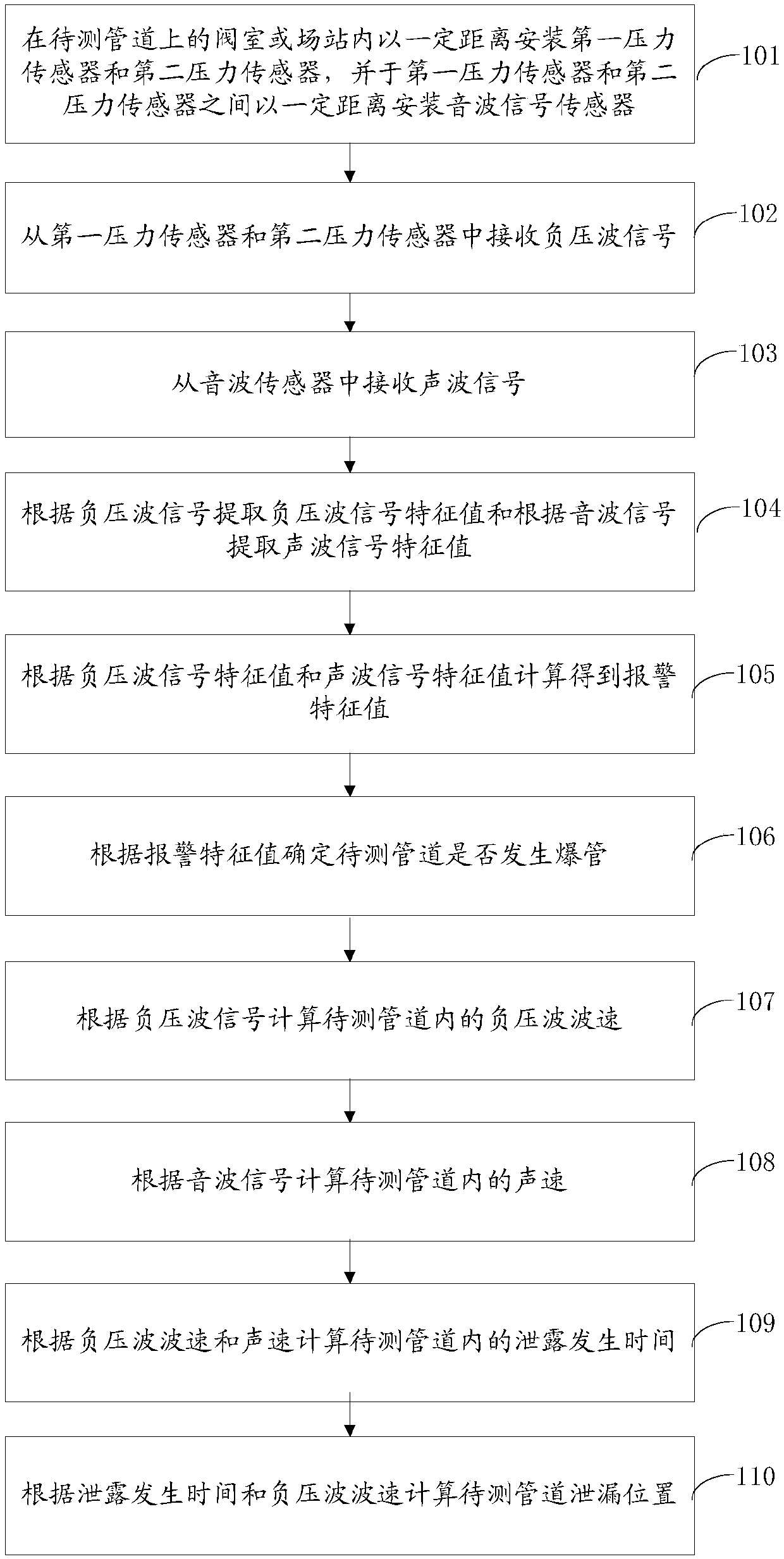

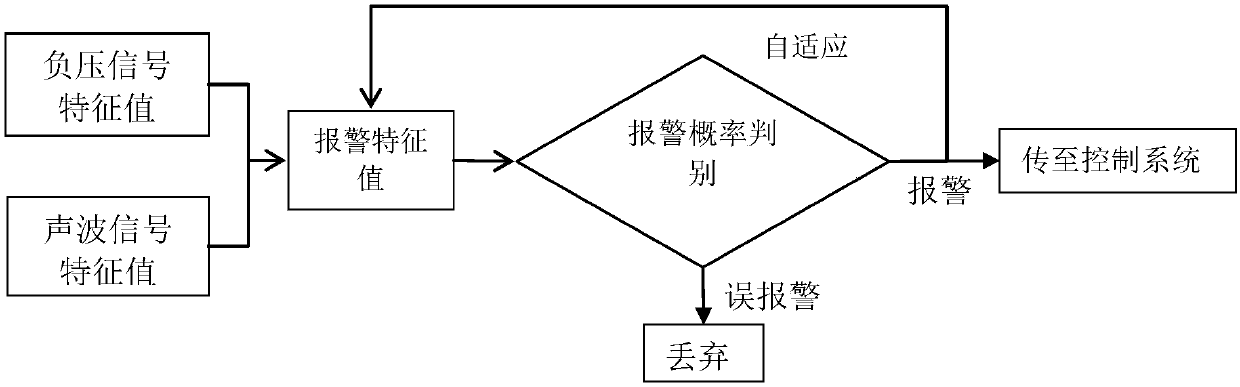

[0045] An embodiment of the present invention provides a method for detecting and locating oil and gas pipeline bursts, see figure 1 , the method flow is as follows:

[0046] Step 101: installing a first pressure sensor and a second pressure sensor at a certain distance in a valve chamber or a field station on the pipeline to be tested, and installing an acoustic signal sensor at a certain distance between the first pressure sensor and the second pressure sensor;

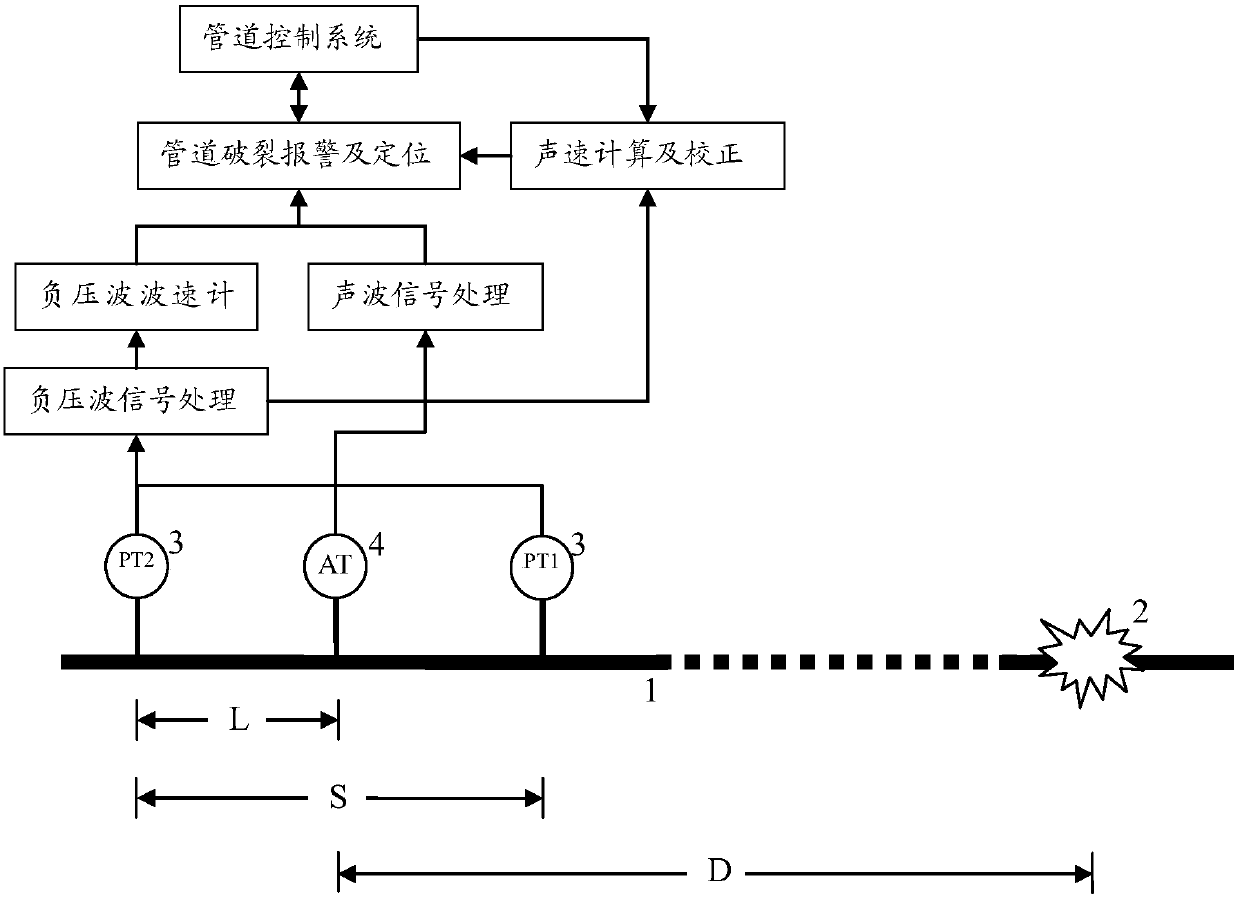

[0047] Specifically, such as figure 2 As shown, the first pressure sensor PT1 and the second pressure sensor PT2 are installed at a certain distance L in the valve chamber or field station on the pipeline to be tested, and a certain distance between the first pressure sensor PT1 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com