Continuous accurate powder weighing, metering and feeding system

A technology for metering feeding and powder, applied in the field of machinery, can solve the problems of interrupted feeding process, feeding discontinuity, prolong feeding process, etc., to achieve stable feeding, good resistance to mechanical vibration interference, and ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

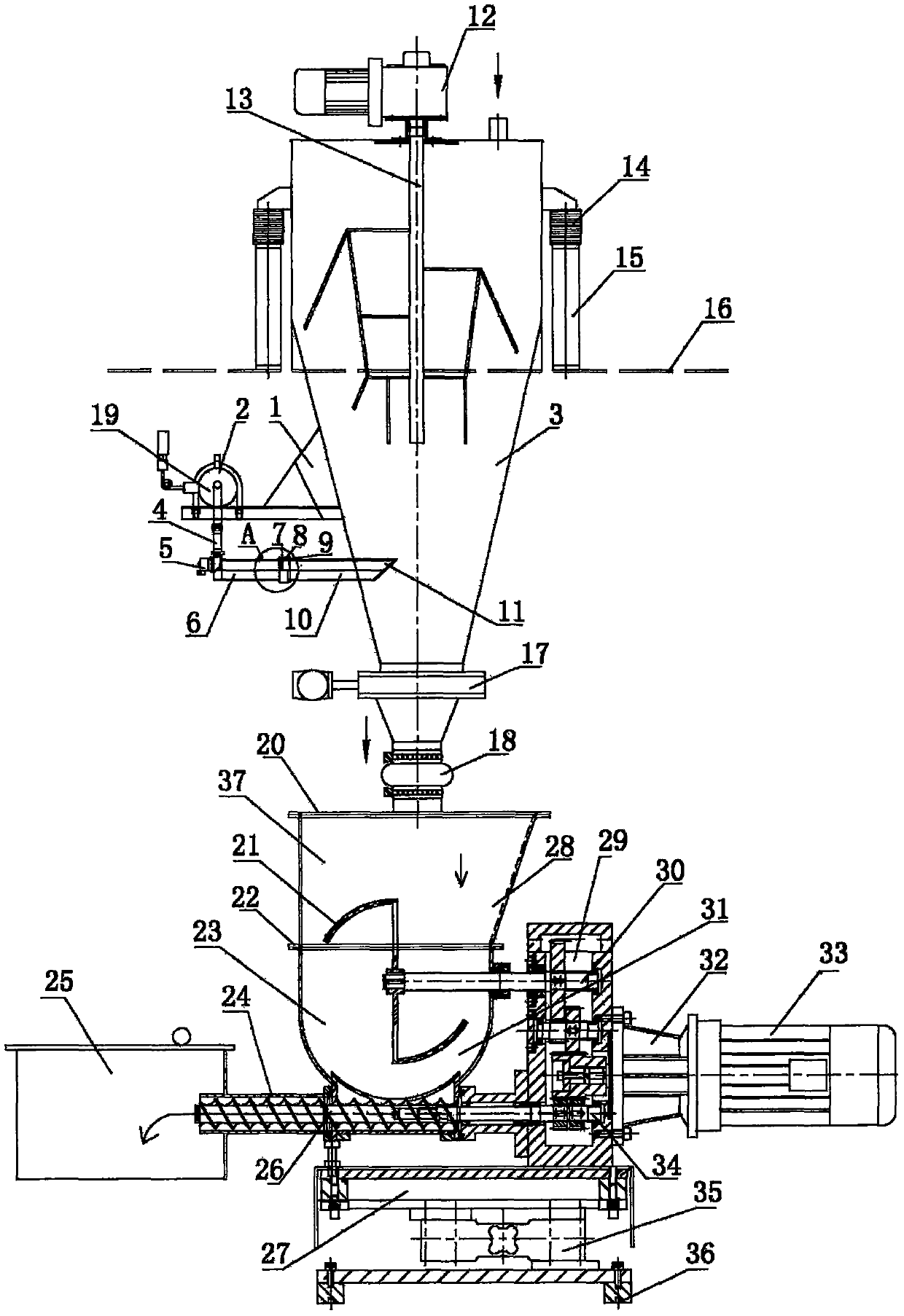

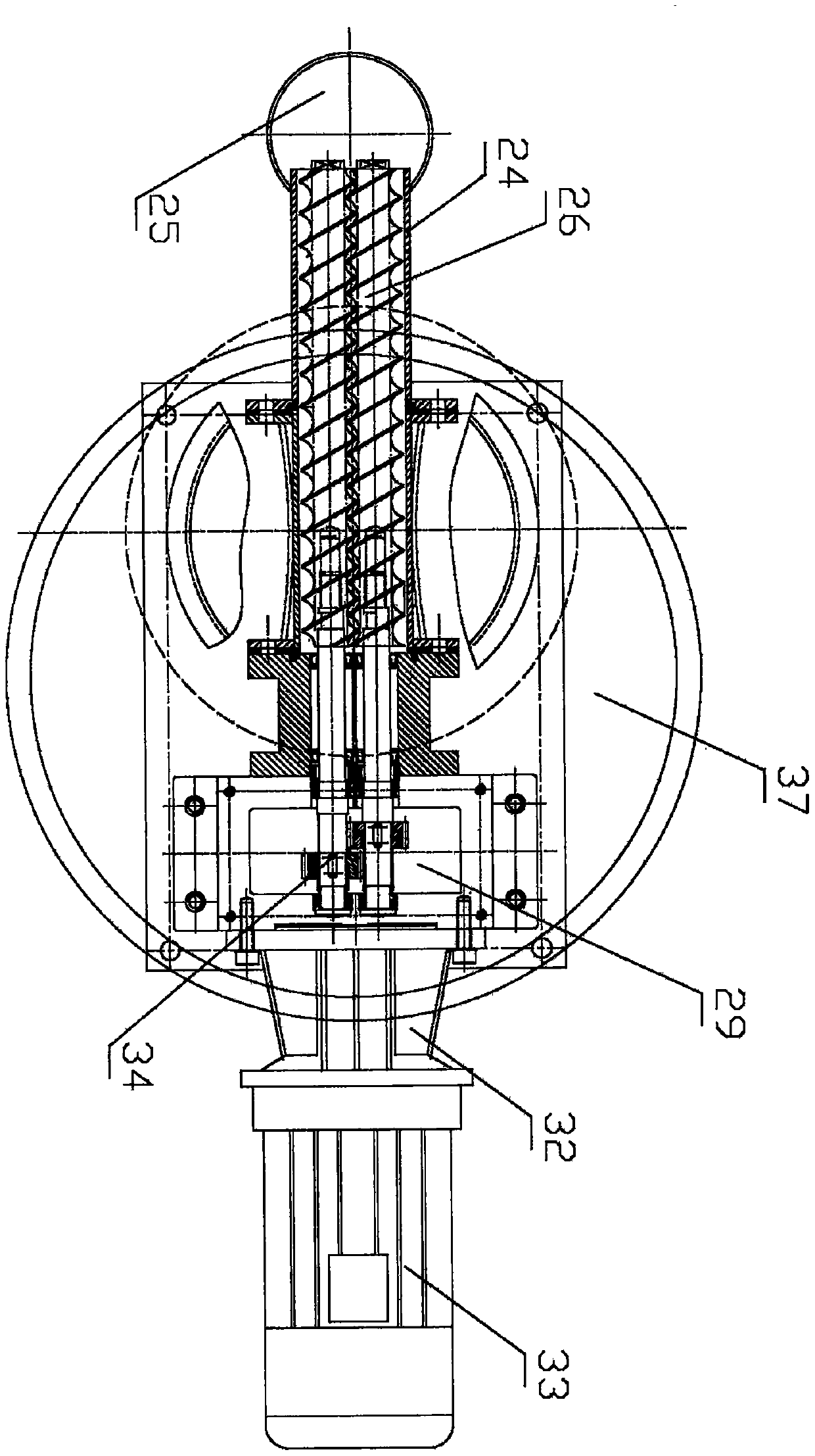

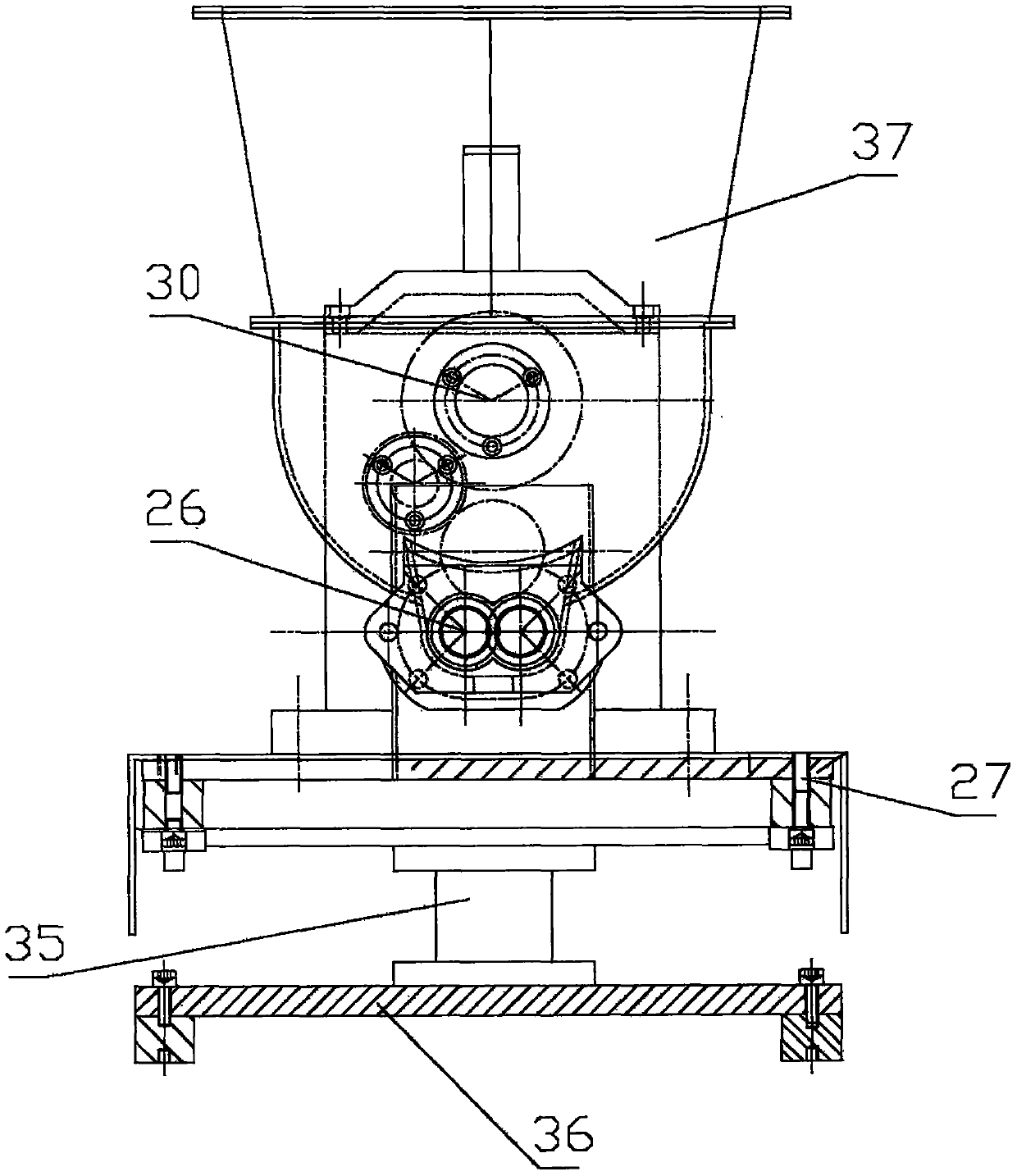

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is a continuous and accurate weighing and metering feeding system for powder, which includes a raw material bin 3, a pneumatic butterfly valve 17, and a twin-screw feeding device 31. The lower part of the raw material bin 3 is provided with a pneumatic butterfly valve 17, which passes through a rubber The soft connecting pipe 18 is connected to the twin-screw feeding device 31, and it is characterized in that: the raw material bin 3 is installed on the steel frame platform 16 through the buffer spring 14 and the support column 15, and the inside of the raw material bin 3 is equipped with a stirring paddle 13, which is connected to Stirring motor 12, a powder material fluidization device 19 is provided on the outer wall of the lower part of the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com