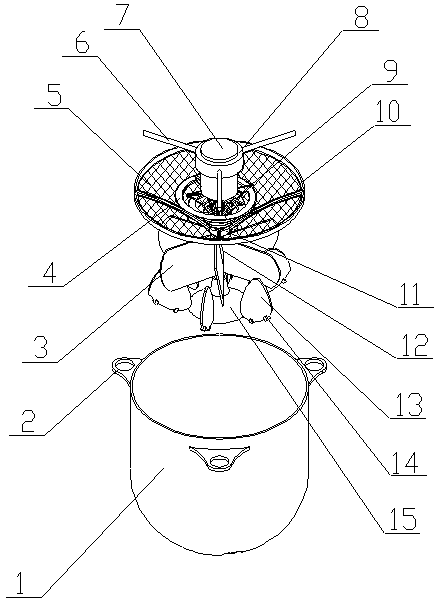

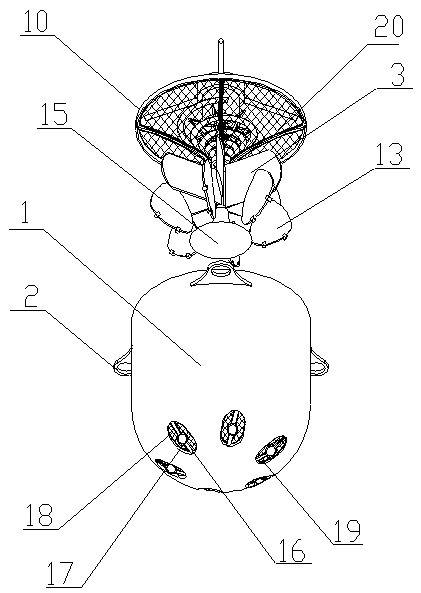

Underground intermittent foam dust-falling spraying nozzle for coal mine construction

A construction well, intermittent technology, applied in the direction of dust prevention, jetting device, mining equipment, etc., can solve the problem of reducing the dust absorption rate of foam, and achieve the effect of improving effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An intermittent foam dust-reducing sprinkler head for underground coal mine construction in the present invention is realized in this way. When in use, when carrying out dust-reducing during underground construction, first install and fix the present invention on the external dust-reducing device through three fixing ears (2), and then install it on the main body Add a certain amount of water and foaming agent into the barrel (1), drive the motor (7) to work, and the motor shaft drives multiple foam plates (9) and spiral stirring blades (4) to rotate, and drives them through the connecting ring (11) The rotating rod (12) rotates, the connecting ring (11) drives the filter screen (5) to rotate through a plurality of arc-shaped rods (20), and the plurality of foam plates (9) and the spiral stirrer (4) respectively rotate to the main cylinder ( 1) Stir the foaming agent and water inside to make it generate foam. At the same time, the spiral stirrer (4) drives the foam to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com