Silicon nanotube composite negative electrode material used for lithium battery and preparation method

A nanotube composite and negative electrode material technology, which is applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems of large volume change and low charge and discharge efficiency, and achieve high reversible specific capacity, Coulombic efficiency is improved, and the effect of thermal diffusion is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

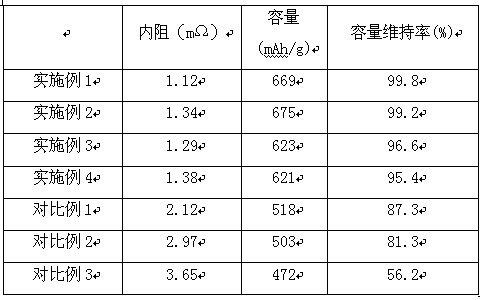

Examples

Embodiment 1

[0030] A preparation method for a silicon nanotube composite negative electrode material for a lithium battery, the steps are as follows:

[0031] (1) Clean and dry the single crystal silicon wafer substrate, and sputter a layer of gold film with a thickness of 3nm on the surface of the silicon wafer by ion sputtering as a catalyst to provide nucleation sites for the growth of silicon dioxide nanotubes Put the corundum boat carrying the zinc sulfide powder and the silicon substrate into the horizontal tube furnace so that the zinc sulfide is located at the center of the high temperature zone of the horizontal tube furnace, the silicon substrate is at the position 15 cm downstream of the zinc sulfide, and the tube furnace is sealed. Introduce a high-purity inert gas as a carrier gas to flush out the residual air in the growth chamber; control the flow rate of the inert gas at 150 sccm, keep the pressure in the growth chamber at 500 Pa, raise the temperature of the tube furnace t...

Embodiment 2

[0036] A preparation method for a silicon nanotube composite negative electrode material for a lithium battery, the steps are as follows:

[0037] (1) Clean and dry the single crystal silicon wafer substrate, and sputter a layer of gold film with a thickness of 5nm on the surface of the silicon wafer by ion sputtering as a catalyst to provide nucleation sites for the growth of silicon dioxide nanotubes; Put the corundum boat carrying zinc sulfide powder and silicon substrate into the horizontal tube furnace, so that the zinc sulfide is located in the center of the high temperature zone of the horizontal tube furnace, and the silicon substrate is located 20 cm downstream of the zinc sulfide, seal the tube furnace, and pass Inject a high-purity inert gas as a carrier gas to flush out the residual air in the growth chamber; control the flow rate of the inert gas at 200 sccm, keep the pressure in the growth chamber at 800 Pa, raise the temperature of the tube furnace to the synthes...

Embodiment 3

[0042] A preparation method for a silicon nanotube composite negative electrode material for a lithium battery, the steps are as follows:

[0043] (1) Clean and dry the single crystal silicon wafer substrate, use an ion sputtering instrument to sputter a layer of gold film with a thickness of 6nm on the surface of the silicon wafer as a catalyst to provide nucleation sites for the growth of silicon dioxide nanotubes Put the corundum boat carrying the zinc sulfide powder and the silicon substrate into the horizontal tube furnace so that the zinc sulfide is located at the center of the high temperature zone of the horizontal tube furnace, the silicon substrate is at the position 10 cm downstream of the zinc sulfide, and the tube furnace is sealed. Introduce a high-purity inert gas as a carrier gas to wash away the residual air in the growth chamber; control the flow rate of the inert gas at 30sccm, keep the pressure in the growth chamber at 80Pa, raise the temperature of the tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com