Grain dryer automatic control device and control method thereof

An automatic control device and drying machine technology, applied in the direction of non-electric variable control, temperature control, control/regulation system, etc., can solve the problems of manpower consumption, high energy consumption of the dryer, inconvenient operation, etc., and achieve improved effect, Improve the level of automation and reduce the effect of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present application will be further explained below in combination with specific embodiments and accompanying drawings.

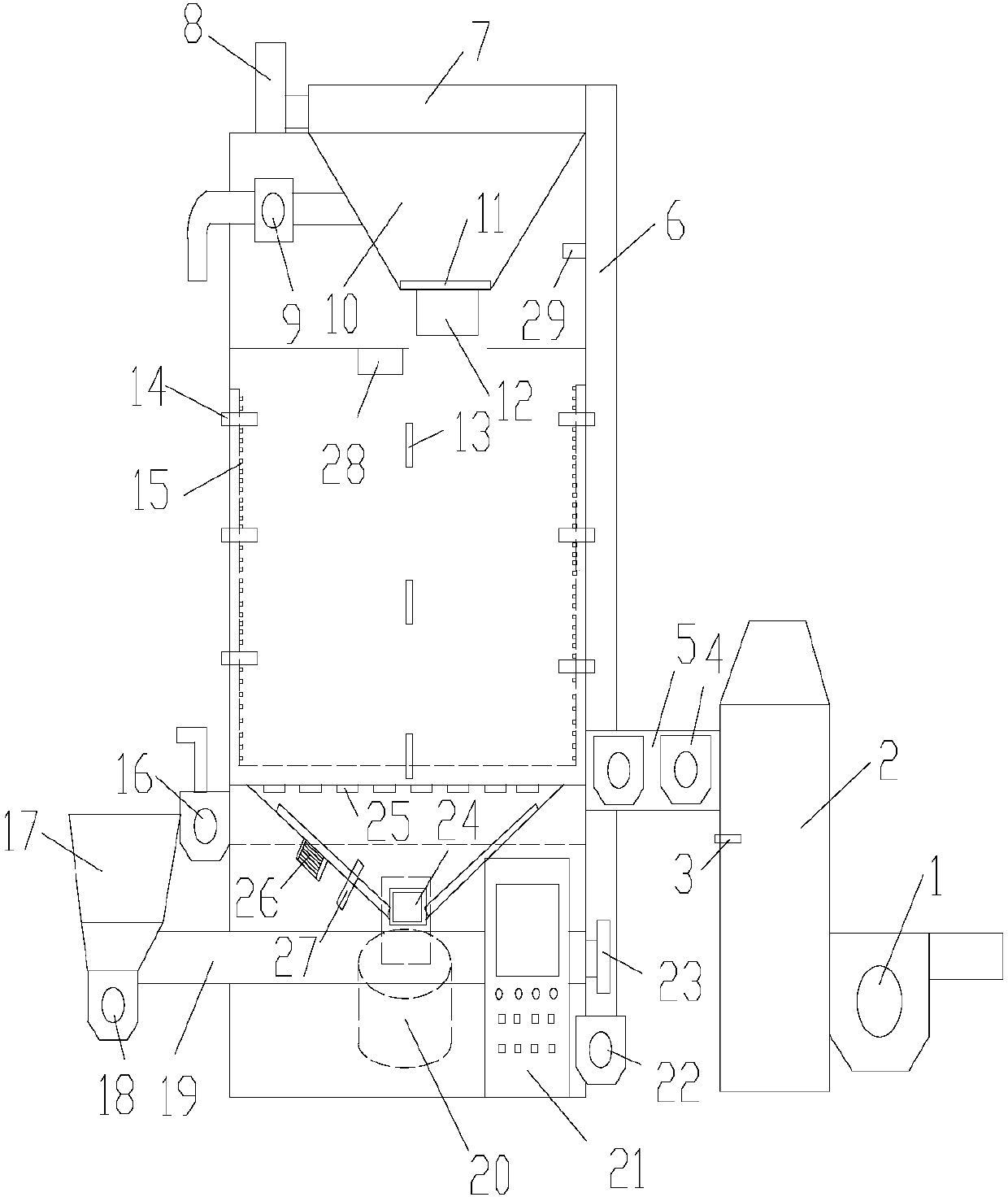

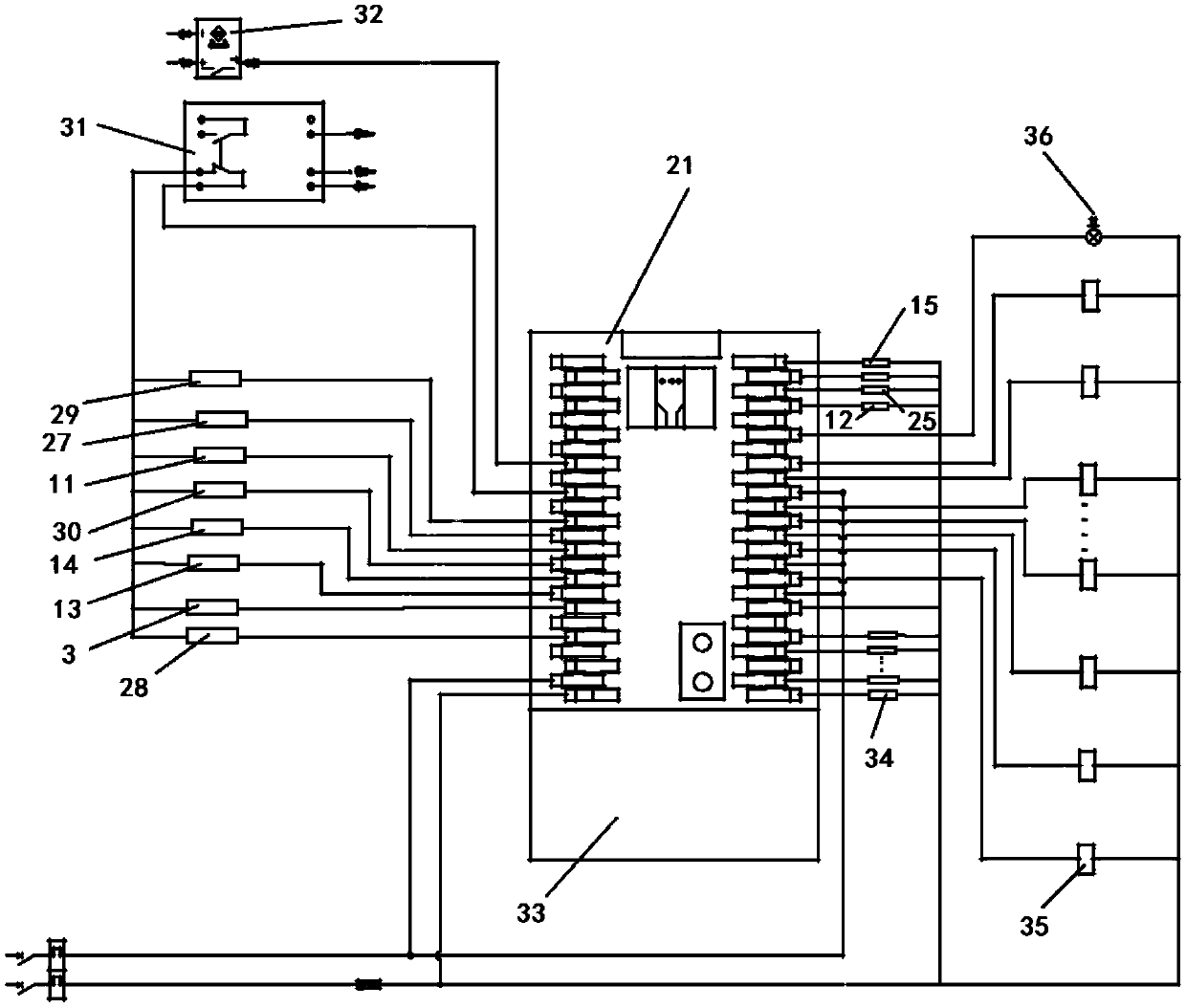

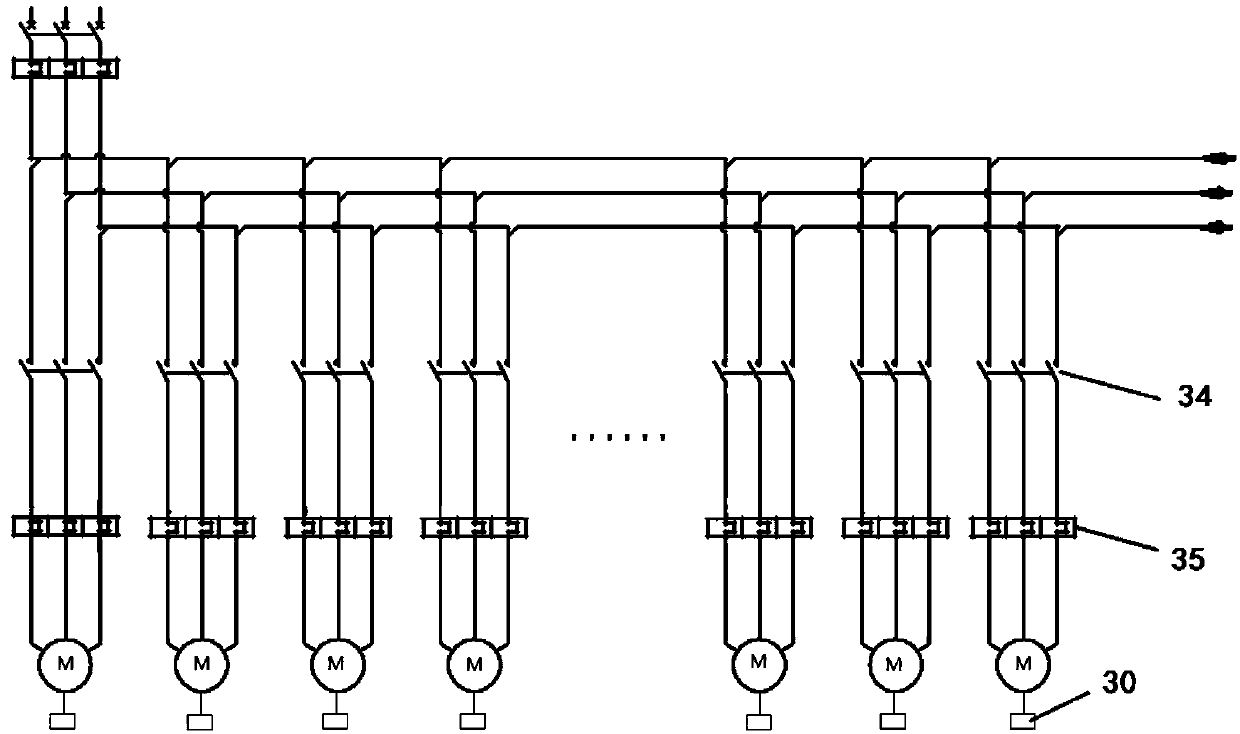

[0025] see figure 1 , the dryer includes a drying tower, the hot air channel of the drying tower is connected to the hot blast stove 2 through the hot air pipe 5, the hot air pipe 5 is provided with the induced draft motor 4, the hot blast stove 2 is connected to the blower motor 1, and the hot blast stove 2 A hot blast stove temperature sensor 3 is arranged on the top, an exhaust motor 16 is connected to the air outlet of the drying tower, an upper auger 7 is arranged on the top of the drying tower, and the upper auger 7 is connected to an upper auger motor 8, and the side wall of the drying tower A hoist 6 is provided, and a hoist motor 22 is arranged on the hoist 6. The bottom of the drying tower is provided with a lower auger 19, the lower auger 19 is connected to the lower auger motor 23, the top of the hoist 6 is connected to the upper auge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com