Liquid silicone rubber composition for cold shrink cable and preparation method of liquid silicone rubber composition

A technology of liquid silicone rubber and composition, applied in the field of liquid silicone rubber composition for cold shrinkable cable and its preparation, can solve the problem of improving the tracking resistance and electrical insulation strength, the liquid silicone rubber composition does not meet the requirements, mechanical The performance cannot fully meet the needs and other problems, so as to improve the ablation resistance, improve the tracking resistance, and improve the tracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

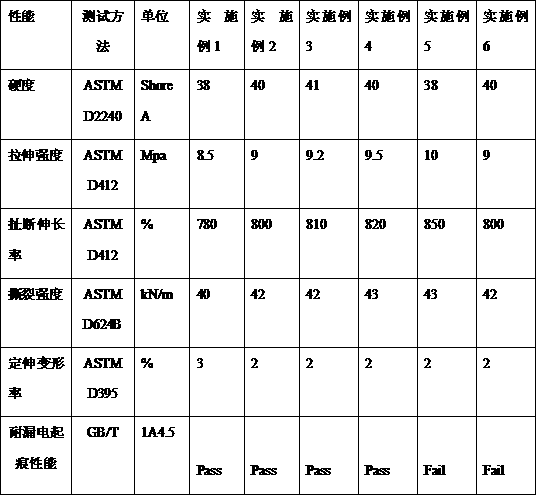

Examples

preparation example Construction

[0043] A preparation method of a liquid silicone rubber composition for cold-shrinkable cables, comprising the following steps:

[0044] (1) Base rubber preparation: 100 parts by mass of vinyl polydimethylsiloxane, 20-50 parts by mass of fumed silica, 5-15 parts by mass of silazane, and 0.1-3 parts by mass of hydroxyl silicone oil In the internal mixer, mix evenly at low temperature first, then raise the temperature to 150°C and mix for 3 hours, cool down to get the base rubber;

[0045] (2) AB glue preparation: 100 parts by mass of the base glue obtained in step (1), plus 1-5 parts by mass of high vinyl silica gel, 5-30 parts by mass of vinyl polysiloxane, and 0.01-10 parts by mass of anti-aging additives Parts by mass, 0.001-0.5 parts by mass of the platinum catalyst were placed in a planetary mixer and mixed evenly to obtain glue A; then 100 parts by mass of the base glue obtained in step (1), plus 5-30 parts by mass of vinyl polysiloxane, -10 parts by mass of cross-linkin...

Embodiment 1

[0048] The invention discloses a liquid silicone rubber composition for cold-shrinkable cables, which comprises the following components in parts by mass: 100 parts by mass of vinyl polydimethylsiloxane, 5 parts by mass of high vinyl silicone oil, and 5 parts by mass of crosslinking agent 0.01 parts by mass of anti-aging additive, 50 parts by mass of fumed silica, 1.1 parts by mass of phenyl silicone oil with high phenyl content, 0.001 parts by mass of aminobenzotriazole or its derivatives, 0.5 parts by mass of platinum catalyst , 0.25 parts by mass of inhibitor.

[0049] In this embodiment, the vinyl polydimethylsiloxane is a polydimethylsiloxane containing vinyl units in its molecule or a mixture of polydimethylsiloxanes with different viscosities. The polydimethylsiloxane has a viscosity of 10,000-150,000 mpas at 25° C., and a vinyl content of 0.1-0.3%. The crosslinking agent is an organopolysiloxane containing at least two Si-H bonds or a mixture of silanes with different...

Embodiment 2

[0056] The invention discloses a liquid silicone rubber composition for cold-shrinkable cables, which comprises the following components in parts by mass: 100 parts by mass of vinyl polydimethylsiloxane, 2.5 parts by mass of high vinyl silicone oil, and 0.1 parts by mass of crosslinking agent 10 parts by mass of anti-aging additives, 35 parts by mass of fumed silica, 0.1 parts by mass of phenyl silicone oil with high phenyl content, 0.5 parts by mass of aminobenzotriazole or its derivatives, 0.025 parts by mass of platinum catalyst , 0.001 parts by mass of inhibitor.

[0057] In this embodiment, the vinyl polydimethylsiloxane is a polydimethylsiloxane containing vinyl units in its molecule or a mixture of polydimethylsiloxanes with different viscosities. The polydimethylsiloxane has a viscosity of 10,000-150,000 mpas at 25° C., and a vinyl content of 0.1-0.3%. The crosslinking agent is an organopolysiloxane containing at least two Si-H bonds or a mixture of silanes with diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com