Method for preparing phosphorus-containing flame-retardant polyether polyol

A technology for flame retardant polyether and polyol, which is applied in the field of preparation of phosphorus-containing flame retardant polyether polyol, can solve the problems of flame retardant performance and mechanical performance defects, application limitations and the like, achieves good mechanical performance, simple preparation method, The effect of high flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

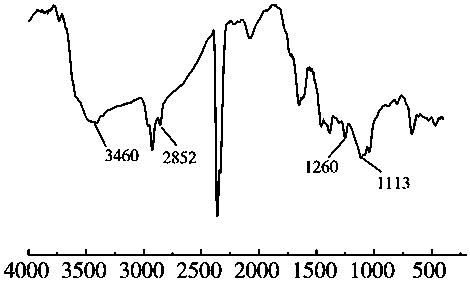

Image

Examples

Embodiment 1

[0020] The preparation method of phosphorus-containing flame-retardant polyether polyol comprises the following steps:

[0021] (1) Add trihydroxymethyl phosphine and KOH into the stainless steel reactor at a mass ratio of 6:1, replace the air in the reactor with nitrogen for 3 times, then raise the temperature to 80°C and keep it warm for 0.5h;

[0022] (2) Add propylene oxide to the product of step (1), then raise the temperature to 110°C, and keep the pressure at 0.2-0.6Mpa, wherein the mass ratio of the product of step (1) to propylene oxide is 10:1.5;

[0023] (3) Release the pressure of the reactor, add phosphoric acid and N,N-dimethylcyclohexylamine to the product of step (2) in sequence, then vacuum dehydrate for 2 hours, filter, and use the filter residue for later use; among them, the product of step (2), The mass ratio of phosphoric acid and N,N-dimethylcyclohexylamine is 10:0.8:1;

[0024] (4) Disperse the obtained filter residue in water, and disperse it ultrason...

Embodiment 2

[0029] The preparation method of phosphorus-containing flame-retardant polyether polyol comprises the following steps:

[0030] (1) Add trihydroxymethyl phosphine and KOH into the stainless steel reactor at a mass ratio of 8:1, replace the air in the reactor with nitrogen for 3 times, then raise the temperature to 80°C and keep it warm for 1.5h;

[0031] (2) Add propylene oxide to the product of step (1), then raise the temperature to 110°C, and keep the pressure at 0.2-0.6Mpa, wherein the mass ratio of the product of step (1) to propylene oxide is 10:1.5;

[0032] (3) Release the pressure of the reactor, add phosphoric acid and N,N-dimethylcyclohexylamine to the product of step (2) in sequence, then vacuum dehydrate for 2 hours, filter, and use the filter residue for later use; among them, the product of step (2), The mass ratio of phosphoric acid and N,N-dimethylcyclohexylamine is 10:0.8:1;

[0033] (4) Disperse the obtained filter residue in water, and disperse it ultrason...

Embodiment 3

[0036] The preparation method of phosphorus-containing flame-retardant polyether polyol comprises the following steps:

[0037] (1) Add trihydroxymethylphosphine and KOH into a stainless steel reactor at a mass ratio of 6:1, replace the air in the reactor with nitrogen for 3 times, then raise the temperature to 80°C and keep it warm for 1 hour;

[0038] (2) Add propylene oxide to the product of step (1), then raise the temperature to 110°C, and keep the pressure at 0.2-0.6Mpa, wherein the mass ratio of the product of step (1) to propylene oxide is 10:1.5;

[0039] (3) Release the pressure of the reactor, add phosphoric acid and N,N-dimethylcyclohexylamine to the product of step (2) in sequence, then vacuum dehydrate for 2 hours, filter, and use the filter residue for later use; among them, the product of step (2), The mass ratio of phosphoric acid and N,N-dimethylcyclohexylamine is 10:0.8:1;

[0040] (4) Disperse the obtained filter residue in water, and disperse it ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com