Stirring device for producing concrete

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixer accessories, etc., can solve the problem of single mixing method of mixture raw materials, achieve the effect of improving adaptability, reducing noise volume, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

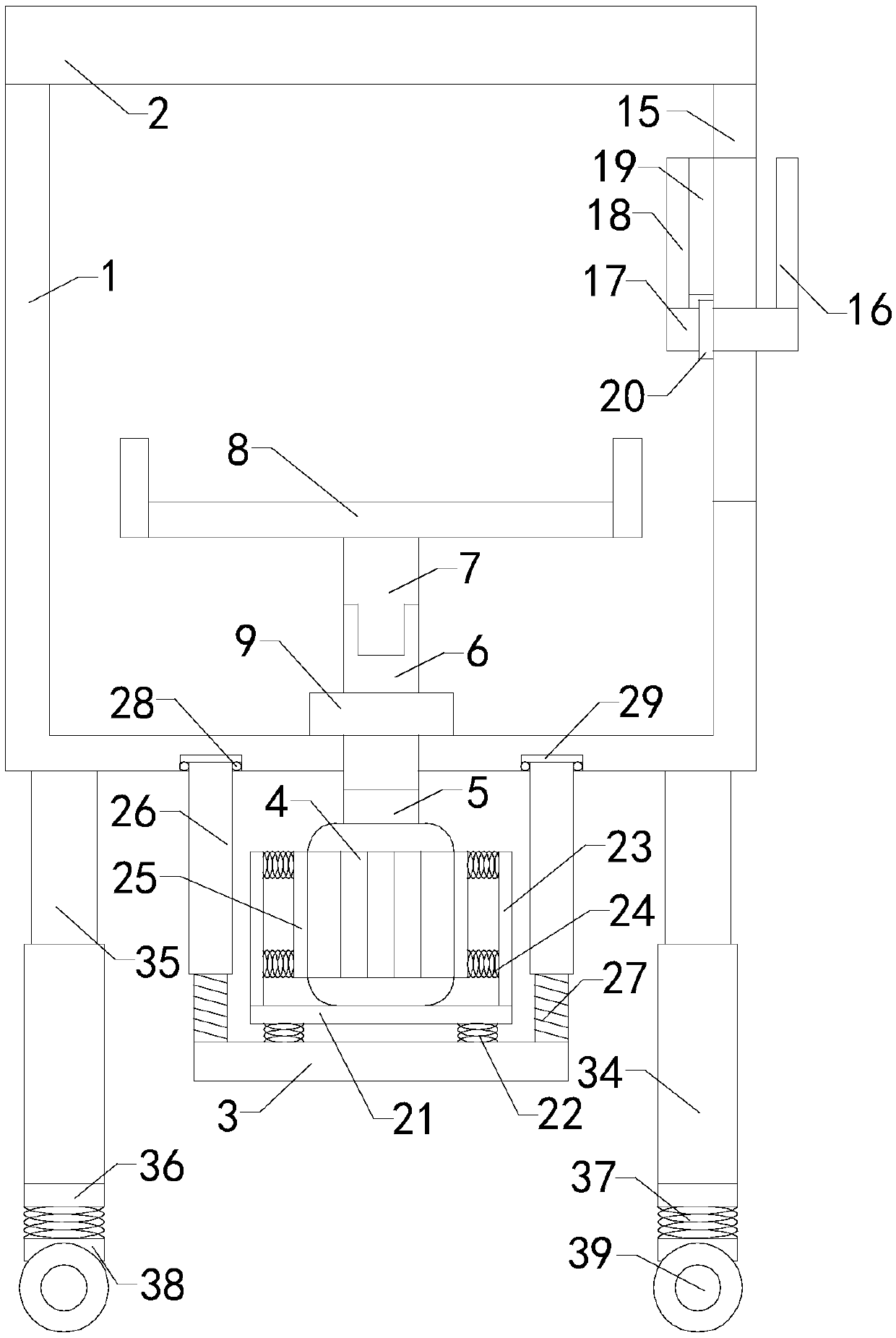

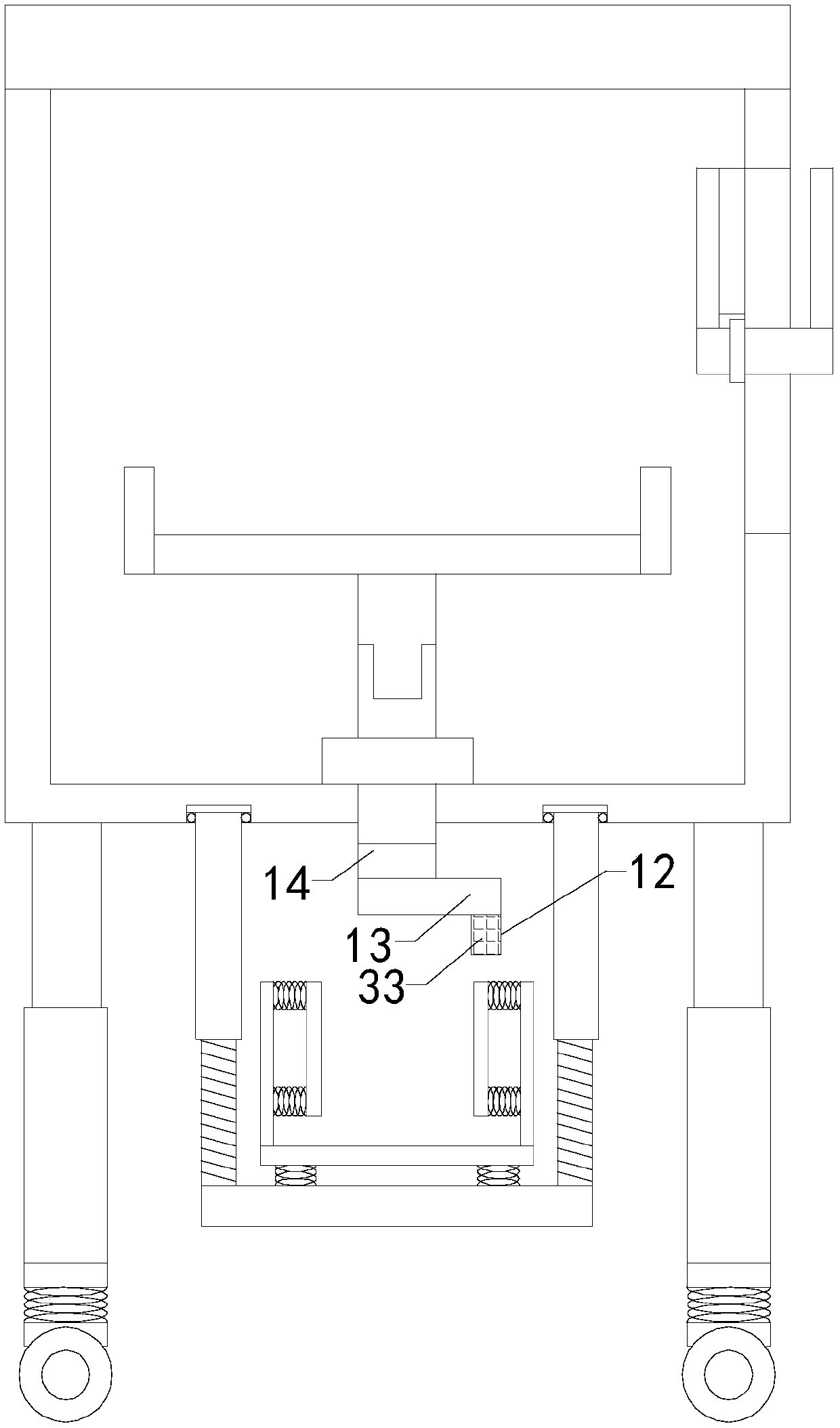

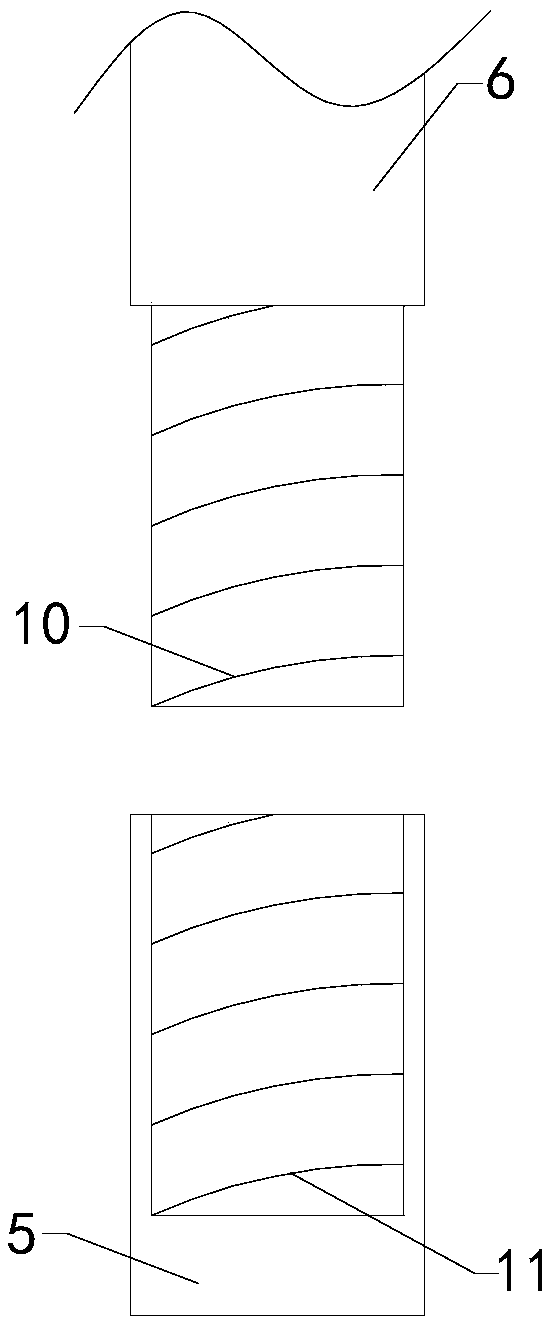

[0017] Such as Figure 1 to Figure 4 As shown, a mixing device for concrete production of the present invention includes a working box 1 and four sets of supports, a working chamber is arranged in the working box, a pick-and-place opening is arranged at the top of the work box, and a stopper is arranged at the pick-and-place mouth. The cover 2 also includes two sets of support columns, a support plate 3, a motor 4, a first connecting rod 5, a connecting column 6, a transmission shaft 7 and a stirring blade 8, the bottom end of the first connecting rod is connected to the output end of the top of the motor, and the connecting column The top end passes through the bottom si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com