Polarizing plate and production method therefor

A manufacturing method and technology for polarizing plates, which are used in polarizing elements, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., to achieve the effect of ensuring convenience, excellent adhesion, and reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0131]

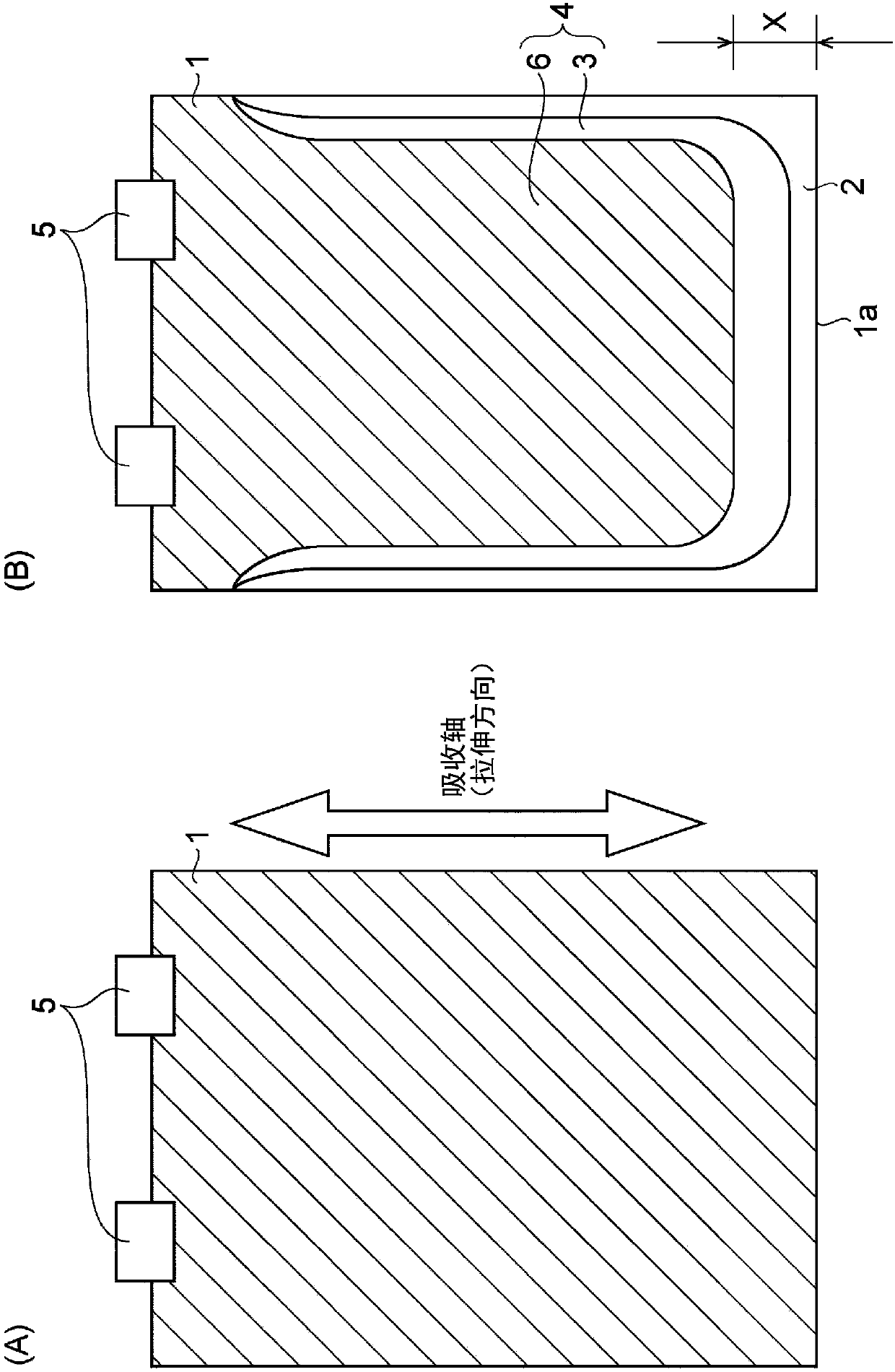

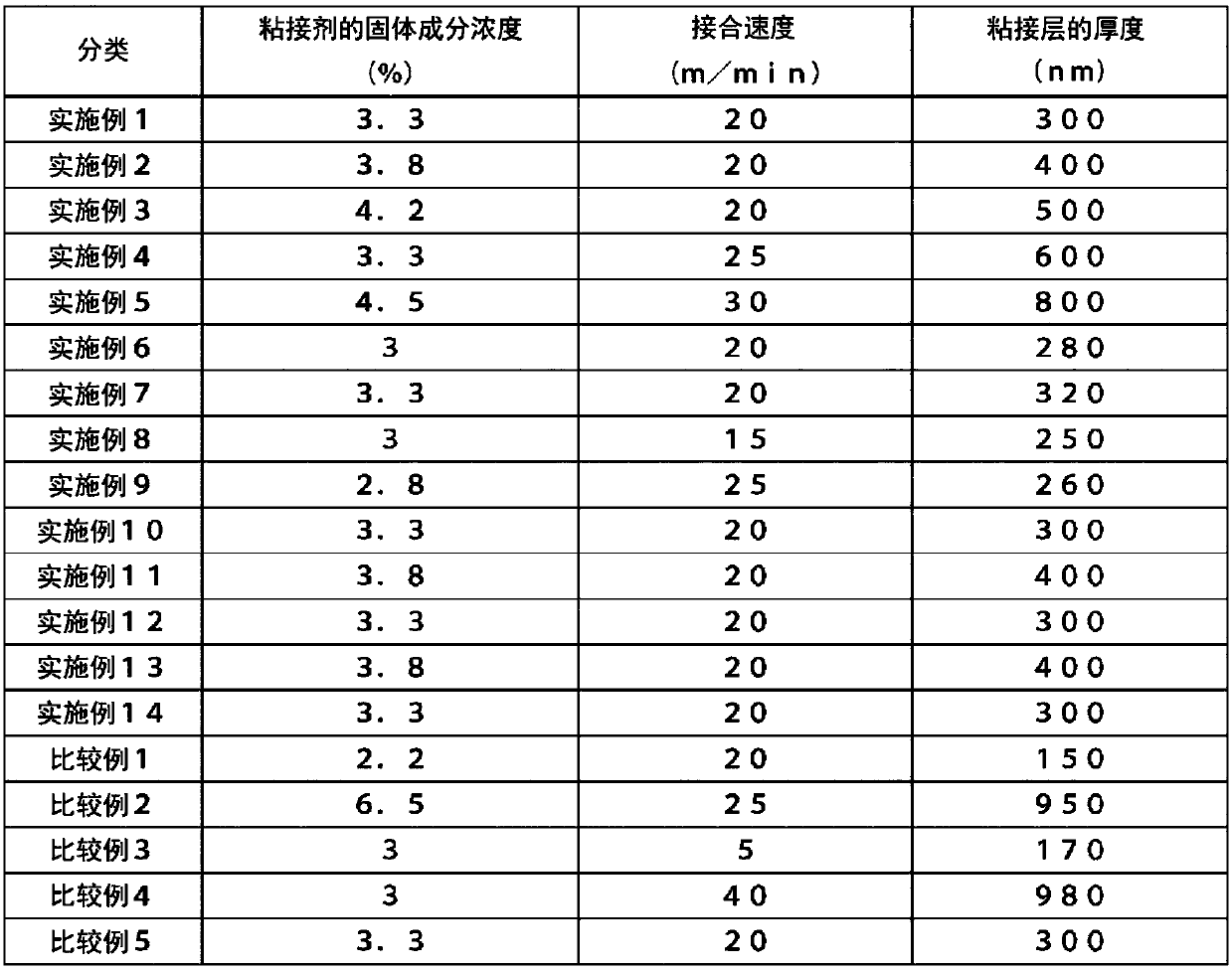

[0132] After a transparent unstretched polyvinyl alcohol film (PE60, KURARAY company) with a saponification degree of 99.9% or more was immersed in water (deionized water) at 25° C. for 1 minute and 20 seconds to swell (swelling step), Dyeing was carried out by immersing for 2 minutes and 30 seconds in a 30°C dyeing aqueous solution containing 1.25 mM / L of iodine, 1.25% by weight of potassium iodide, and 0.3% by weight of boric acid (dyeing step). At this time, in the swelling and dyeing steps, stretching was performed at stretching ratios of 1.56 times and 1.64 times, respectively, so that the cumulative stretching ratio up to the dyeing tank was 2.56 times. Then, while immersing in a cross-linking aqueous solution at 56° C. containing 13.9% by weight of potassium iodide and 3% by weight of boric acid for 26 seconds (the first cross-linking step) to cross-link, stretching was carried out at a stretching ratio of 1.7 times. stretch. Thereafter, while immersing in a...

manufacture example 2

[0141]

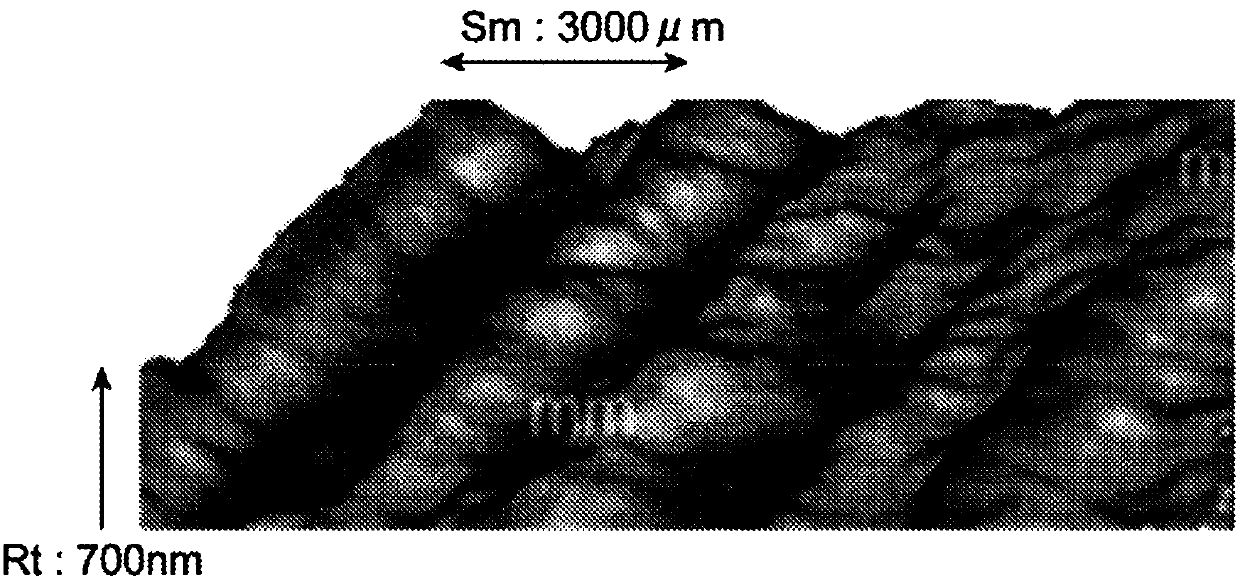

[0142] Except that the temperature of the first and second crosslinking steps was changed from 56°C to 59°C, and the total cumulative stretch ratio of the swelling, dyeing, crosslinking, and color correction steps was changed to 6.1 times, the same method as in Production Example 1 was produced. polarizer. (Unevenness of stripe pattern: Lv3, RSm=3700 μm, Rt=790 nm).

manufacture example 3

[0143]

[0144] In addition to changing the temperature of the first and second crosslinking steps from 56°C to 59°C, changing the boric acid in the crosslinking aqueous solution of the first and second crosslinking steps from 3% by weight to 3.6% by weight, and changing the swelling, A polarizing plate was produced in the same manner as in Production Example 1, except that the total cumulative draw ratio in the steps of dyeing, crosslinking, and color correction was changed to 6.3 times. (Unevenness of stripe pattern: Lv3, RSm=4900 μm, Rt=950 nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com