Composite component and method for producing a composite component

A technology of composite components and metal alloys, applied in applications, household appliances, household components, etc., can solve the problem of high manufacturing cost and achieve the effect of effective heat barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

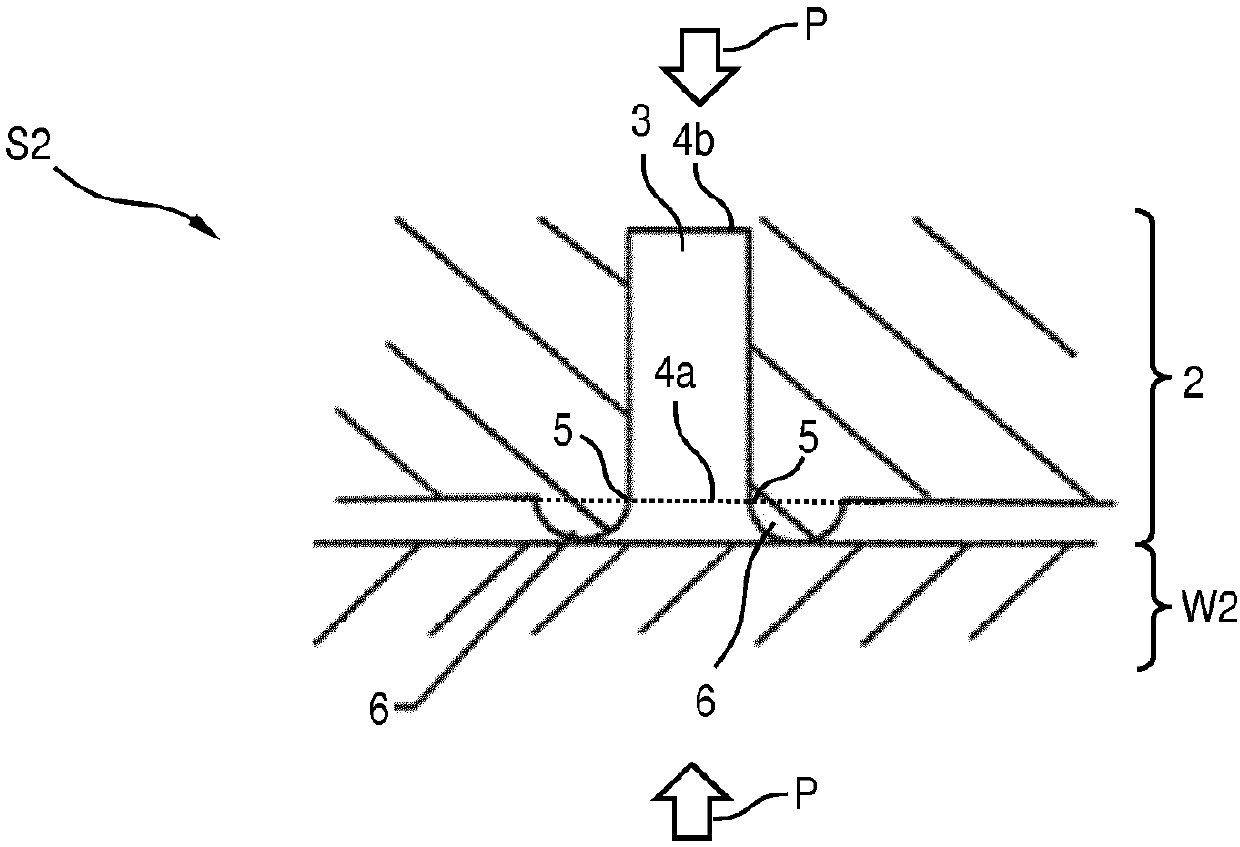

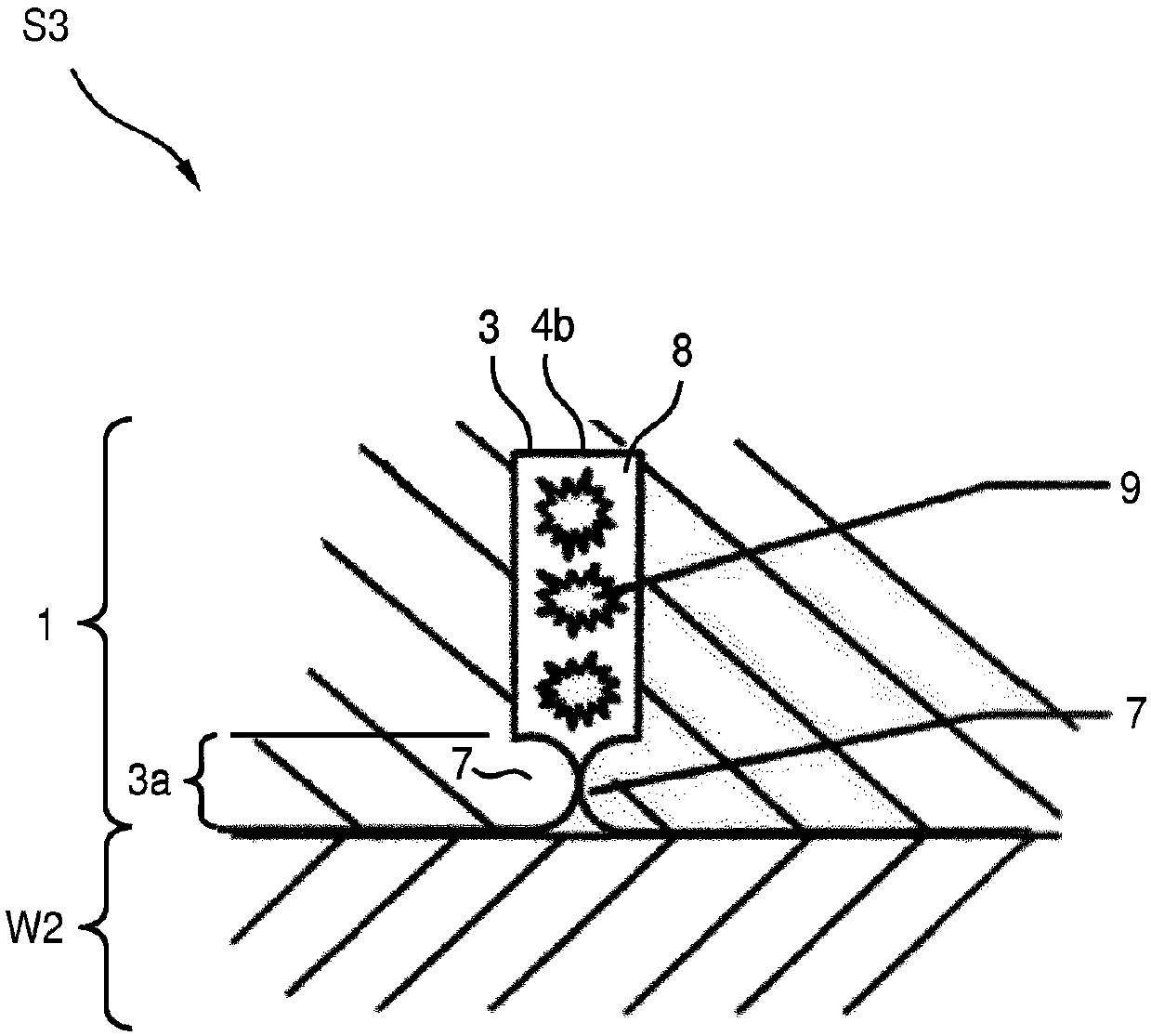

[0033] figure 1 A cross-sectional view showing a first step S1 of the method for manufacturing a composite component 1 (see image 3 ), wherein only the associated components are partially shown.

[0034] In step S1 , the molded body 2 is formed from plastic, for example polycarbonate here, advantageously by injection molding with the aid of a first (“casting”) tool as casting mold. The mold is very simple, since the molded body 2 can be a simple imitation of the first tool W1.

[0035] The molded body 2 produced in this way has at least one depression 3 , which has, for example, a rectangular cross-sectional shape. The depression 3 is, for example, elongated in its longitudinal direction (perpendicular to the plane of the drawing) and can thus be referred to or regarded as a groove or elongated groove. Depression 3 in figure 1 neutralize figure 2 is shown with a port opening 4a pointing downwards and a bottom or base 4b above it.

[0036] The depression 3 transitions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com