Method for improving high and low voltage ride-through capability of auxiliary engine frequency converter of thermal power generation unit

A technology of high and low voltage ride through and low voltage ride through, which is applied in the low voltage ride through capability and improves the high performance of thermal power unit auxiliary frequency converters, and can solve problems such as expensive equipment, hazards to the safe and stable operation of power grids and generator sets, and frequent failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for improving the high and low voltage ride-through capability of a thermal power unit auxiliary frequency converter, characterized in that:

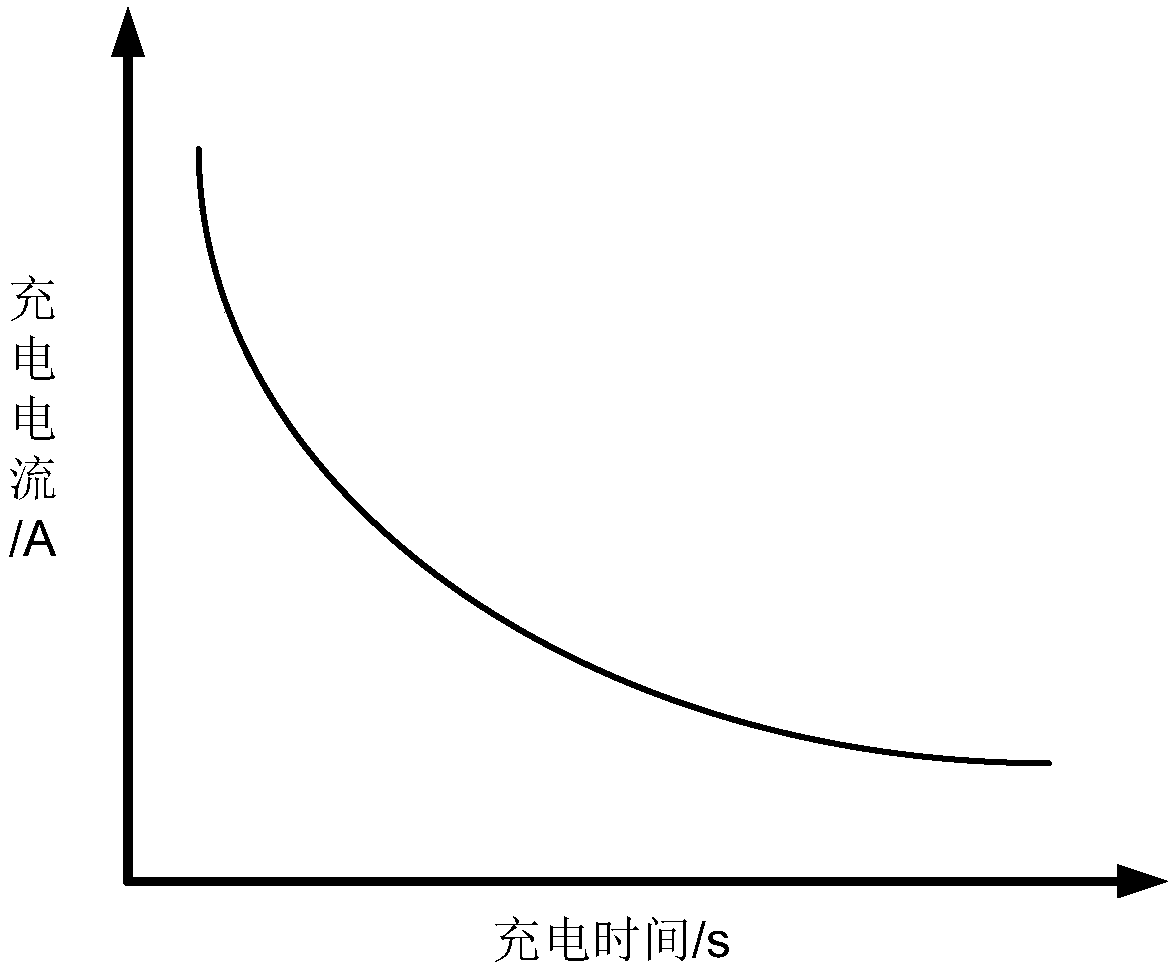

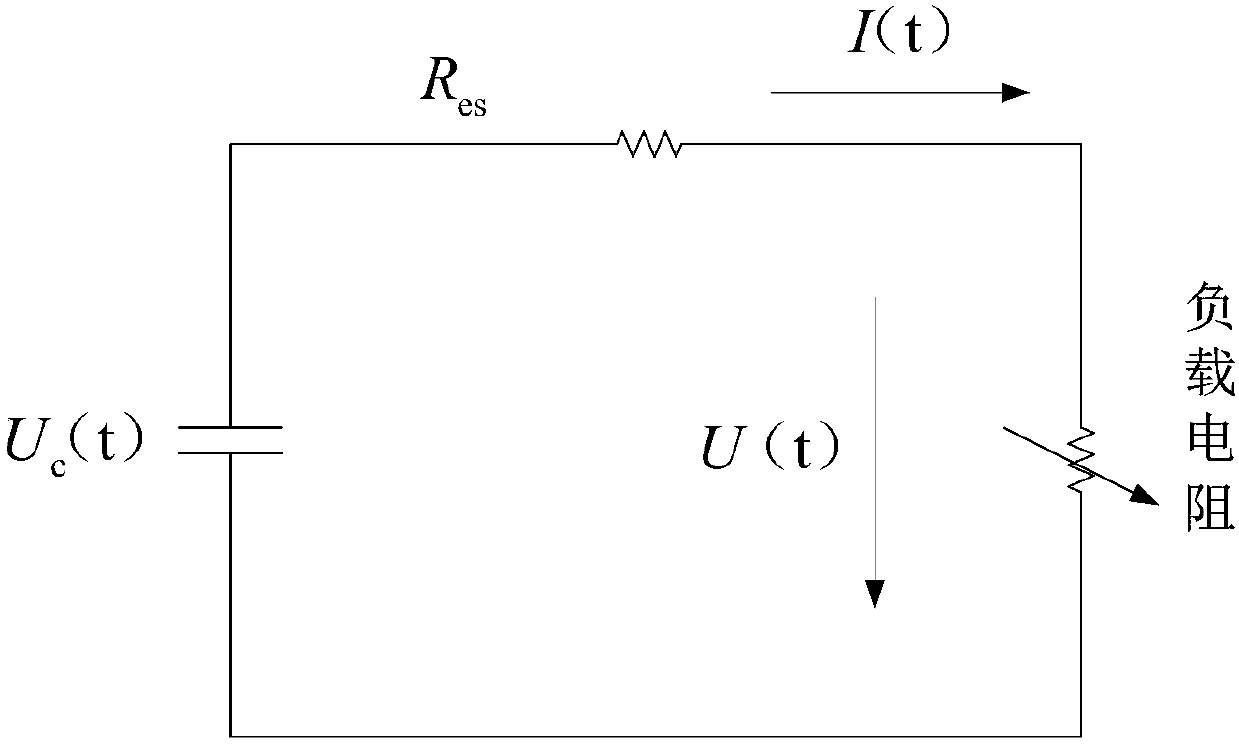

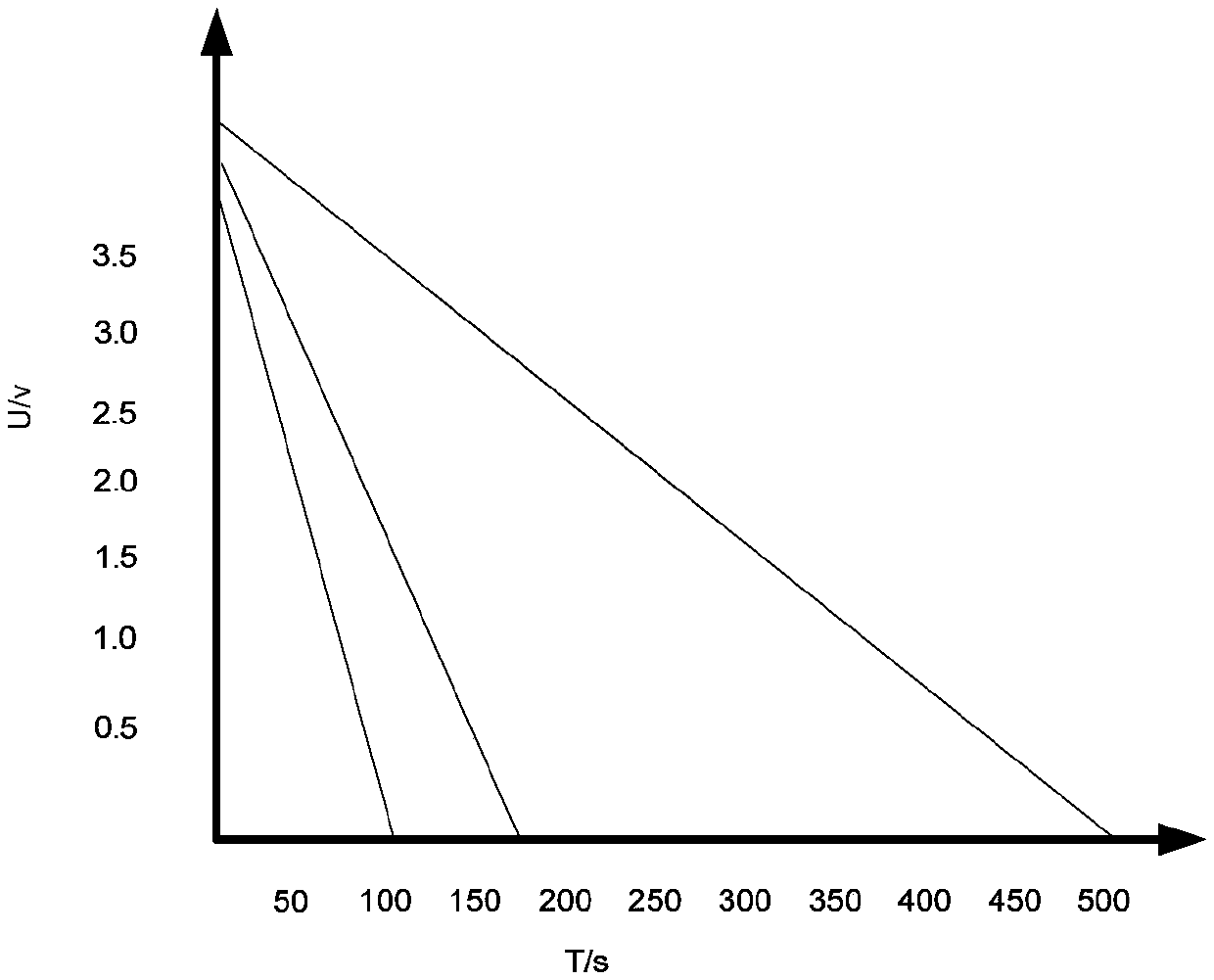

[0020] 1) Low-voltage ride-through method: When the voltage of the power supply line drops, provide DC power support to the inverter in the frequency converter through the low-voltage ride-through capacitor, specifically:

[0021] Equipped with a low-voltage ride-through capacitor on the DC side of the inverter, the terminal voltage of the low-voltage ride-through capacitor is lower than the DC voltage value of the inverter, and a reverse diode is connected in series between the DC side of the inverter and the low-voltage ride-through capacitor; When falling, the low-voltage ride-through capacitor uses the freewheeling diode as a channel to provide DC energy to the inverter, so that the inverter can maintain stable operation within a certain period of time;

[0022] 2) High-voltage ride-through method: When the AC voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com