Leather surface salient defect detection method, system and apparatus

A detection method, a significant technology, applied in the direction of image data processing, instrument, character and pattern recognition, etc., can solve the problems of inefficient recognition and detection, huge amount of calculation, poor versatility of image preprocessing algorithm, etc., to achieve work processing efficiency , Improve processing efficiency, improve versatility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

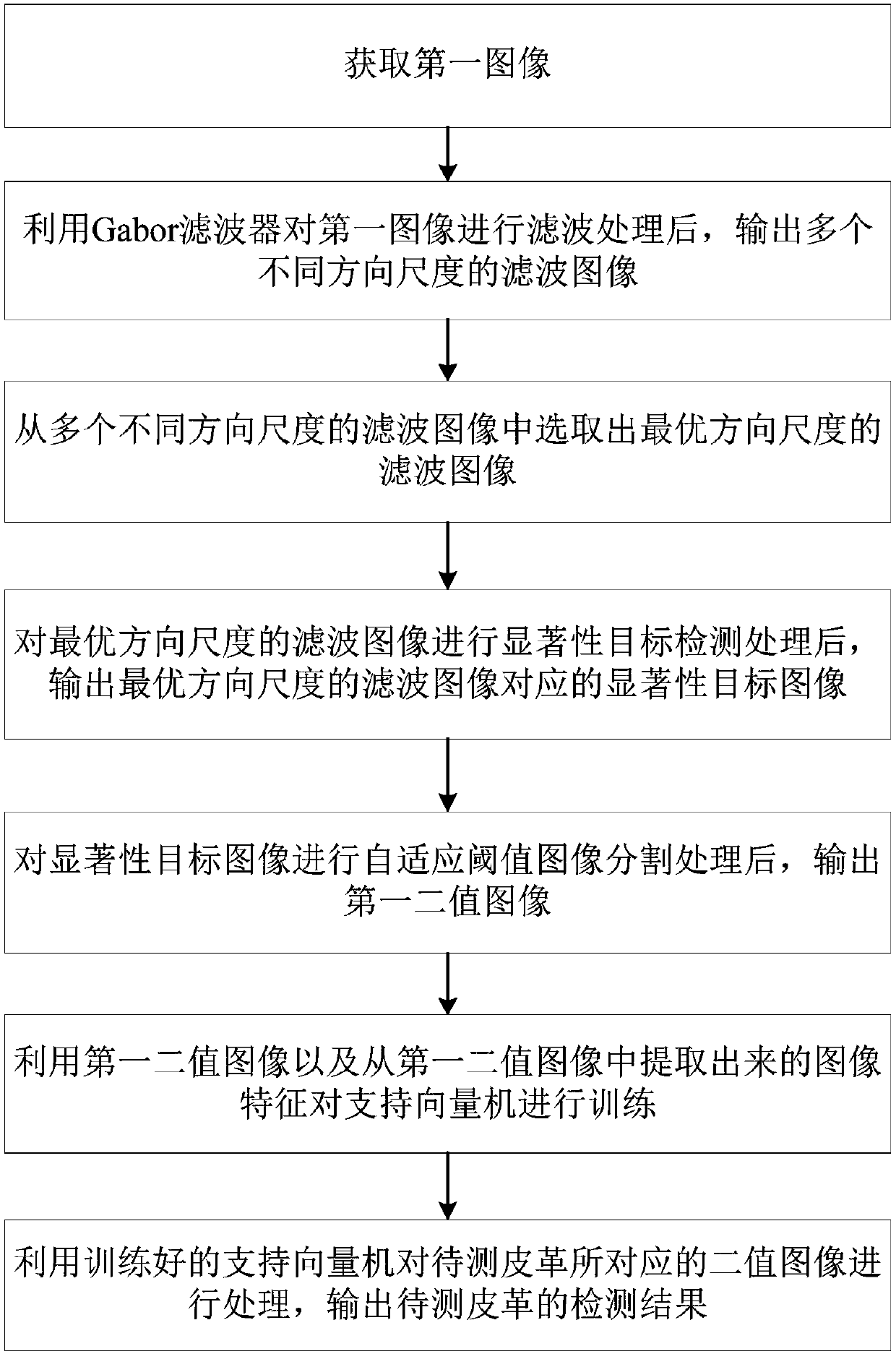

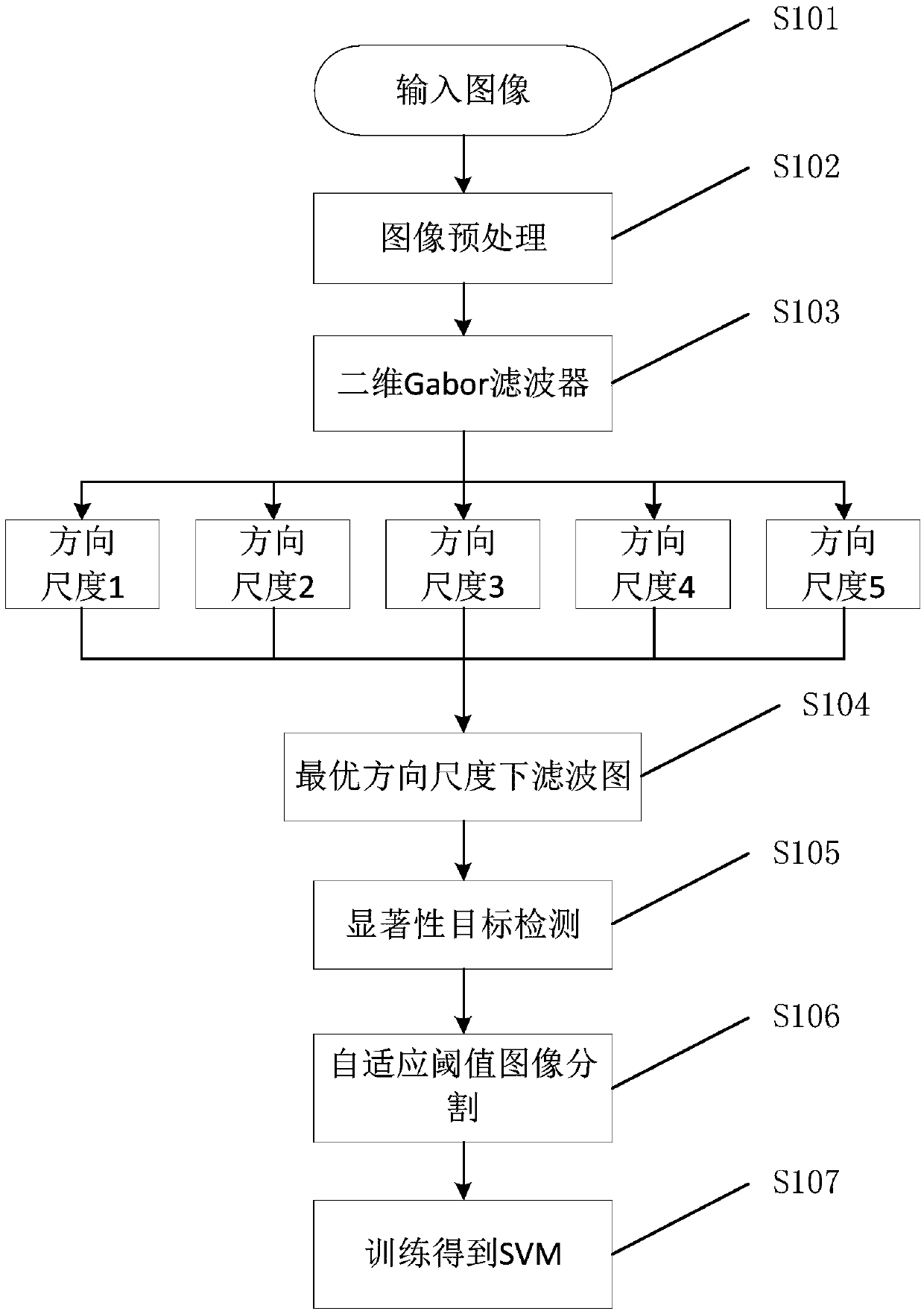

[0061] like figure 1 Shown, a kind of detection method of leather surface significant defect, this method comprises the following steps:

[0062] acquiring a first image, wherein the first image refers to an image of a leather defect detection sample;

[0063] After the Gabor filter is used to filter the first image, a plurality of filtered images of different direction scales are output;

[0064] Selecting a filtered image with an optimal direction scale from a plurality of filtered images with different direction scales;

[0065] After performing salient target detection processing on the filtered image of the optimal direction scale, output a salient target image corresponding to the filtered image of the optimal direction scale;

[0066] After performing adaptive threshold image segmentation processing on the salient target image, the first binary image is output;

[0067] Utilizing the first binary image and image features extracted from the first binary image to train...

Embodiment 2

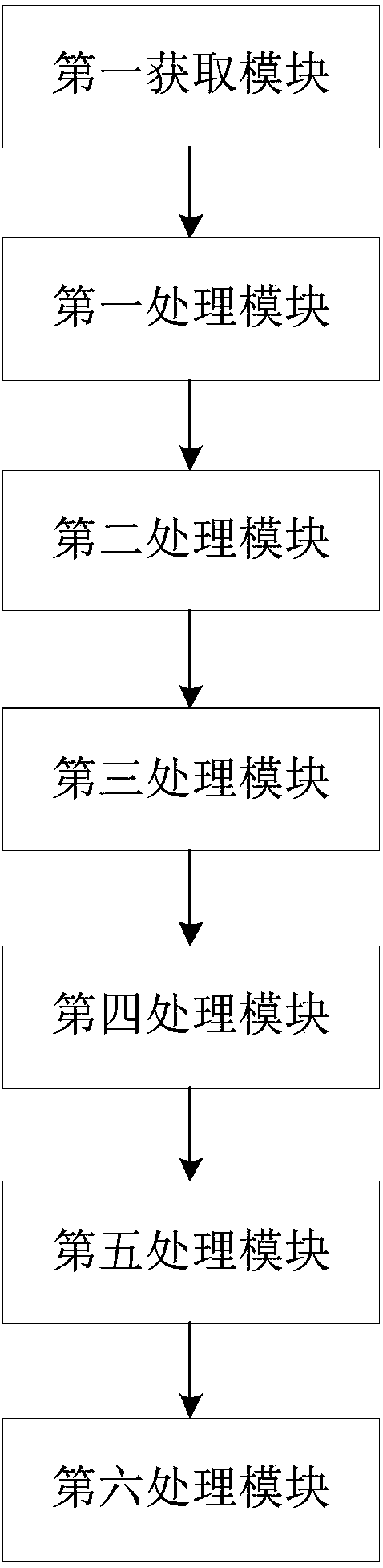

[0089] like figure 2 As shown, a detection system for significant defects on the leather surface, the system includes:

[0090] A first acquisition module, configured to acquire a first image, wherein the first image refers to an image of a leather defect detection sample;

[0091] The first processing module is used to output a plurality of filtered images of different direction scales after filtering the first image by using a Gabor filter;

[0092] The second processing module is used to select a filtered image with an optimal direction scale from a plurality of filtered images with different direction scales;

[0093] The third processing module is configured to output a salient target image corresponding to the filtered image of the optimal direction scale after performing salient target detection processing on the filtered image of the optimal direction scale;

[0094] The fourth processing module is configured to output the first binary image after performing adaptiv...

Embodiment 3

[0112] A device corresponding to the above method, a device for detecting significant defects on the leather surface, the device comprising:

[0113] memory for storing at least one program;

[0114] The processor is configured to load at least one program and execute the steps of the method for detecting significant defects on the leather surface of Embodiment 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com