Convenient product quality detection device

A technology of product quality and testing equipment, which is applied to the direction of testing material strength, measuring devices, and instruments using one-time impact force. Improve accuracy, stability, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

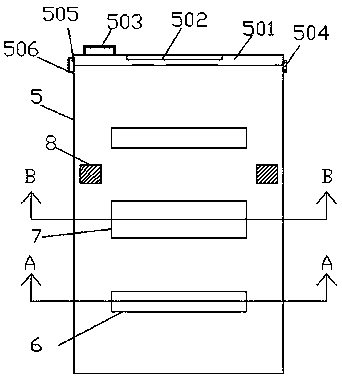

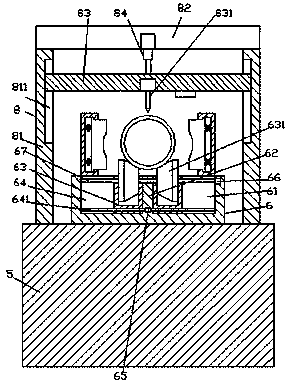

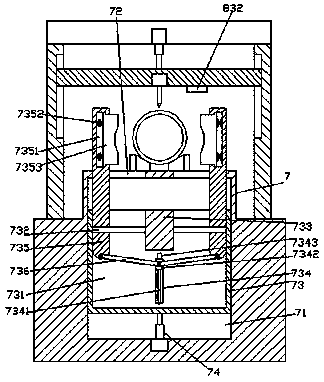

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, a convenient product quality testing device of the present invention includes a housing 5, the upper surface of the housing 5 is provided with a clamping device 7 and an adjusting device arranged on the front and rear sides of the clamping device 7 and oppositely arranged. Transformation device 6, detection frame 8 is provided on the housing 5 between the clamping device 7 and the rear side of the modulation device 6, and each of the modulation devices 6 is provided with a left and right relative arrangement The first sliding connection groove 64 and the second sliding connection groove 61, a wall plate 62 is provided between the first sliding connection groove 64 and the second sliding connection groove 61, and the first sliding connection groove 64 and the Supports 63 are provided in the second sliding groove 61, and the insides of the supports 63 on the left and right sides are provided with runners 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com