Water feeding connector device for passenger car

A technology for water joints and water pipe joints, applied in mechanical equipment, couplings, etc., can solve the problems of high labor intensity, troublesome disassembly and assembly, defects in sealing performance, etc., to reduce labor intensity, simple device structure, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

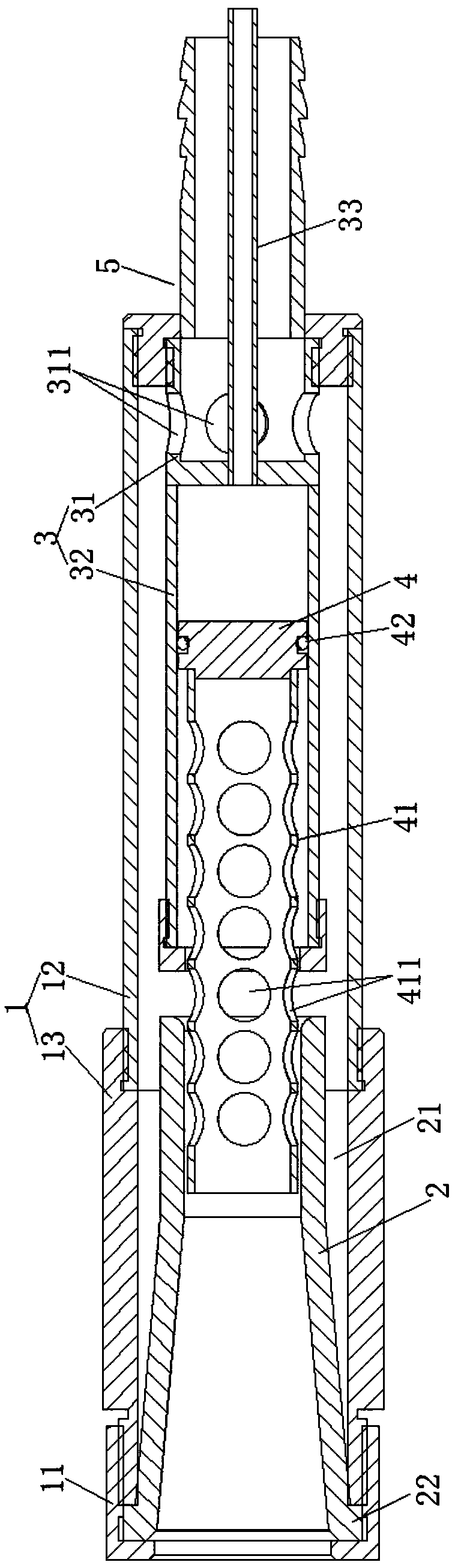

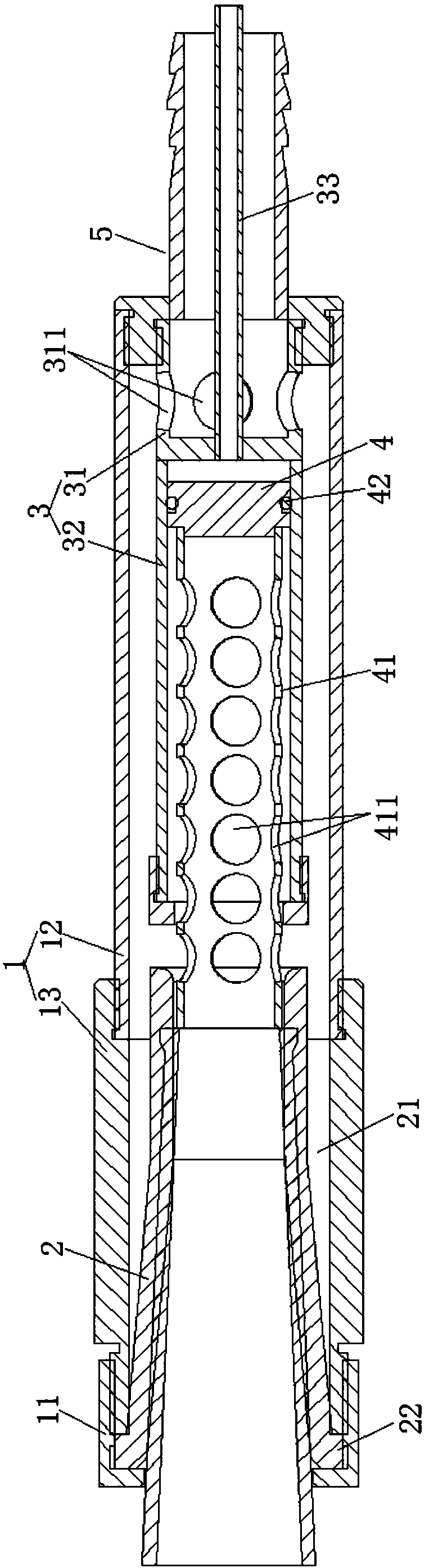

[0035] Example: such as figure 1 and 2 As shown, the passenger car water supply joint device of the present embodiment includes a pipe body 1, a rubber sleeve 2, a guide cylinder 3, a piston 4 and a water pipe joint 5;

[0036] The above-mentioned pipe body 1 is hollow inside and has openings at both ends;

[0037] The above-mentioned water pipe joint 5 is sealed and detachably installed at one end opening of the above-mentioned pipe body 1;

[0038] The above-mentioned rubber sleeve 2 is hollow inside and open at both ends, and is sealed and installed in the open end of the other end of the above-mentioned pipe body 1, and a compression chamber 21 is formed between its side wall and the inner wall of the other end of the above-mentioned pipe body 1;

[0039] The above-mentioned guide cylinder 3 is a cylinder with both ends open, and is sleeved inside the above-mentioned pipe body 1, and is divided into two mutually independent and coaxially arranged water inlet chambers 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com