Subarea design method for prefabricating assembled temporary road for enclosed building construction site

A technology for building construction and prefabrication, applied in roads, roads, buildings, etc., can solve the problems of increased urban environmental protection burden, unfavorable nearby environment, and labor costs, achieve concise and scientific definition of road functions, optimize pavement structure, and reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

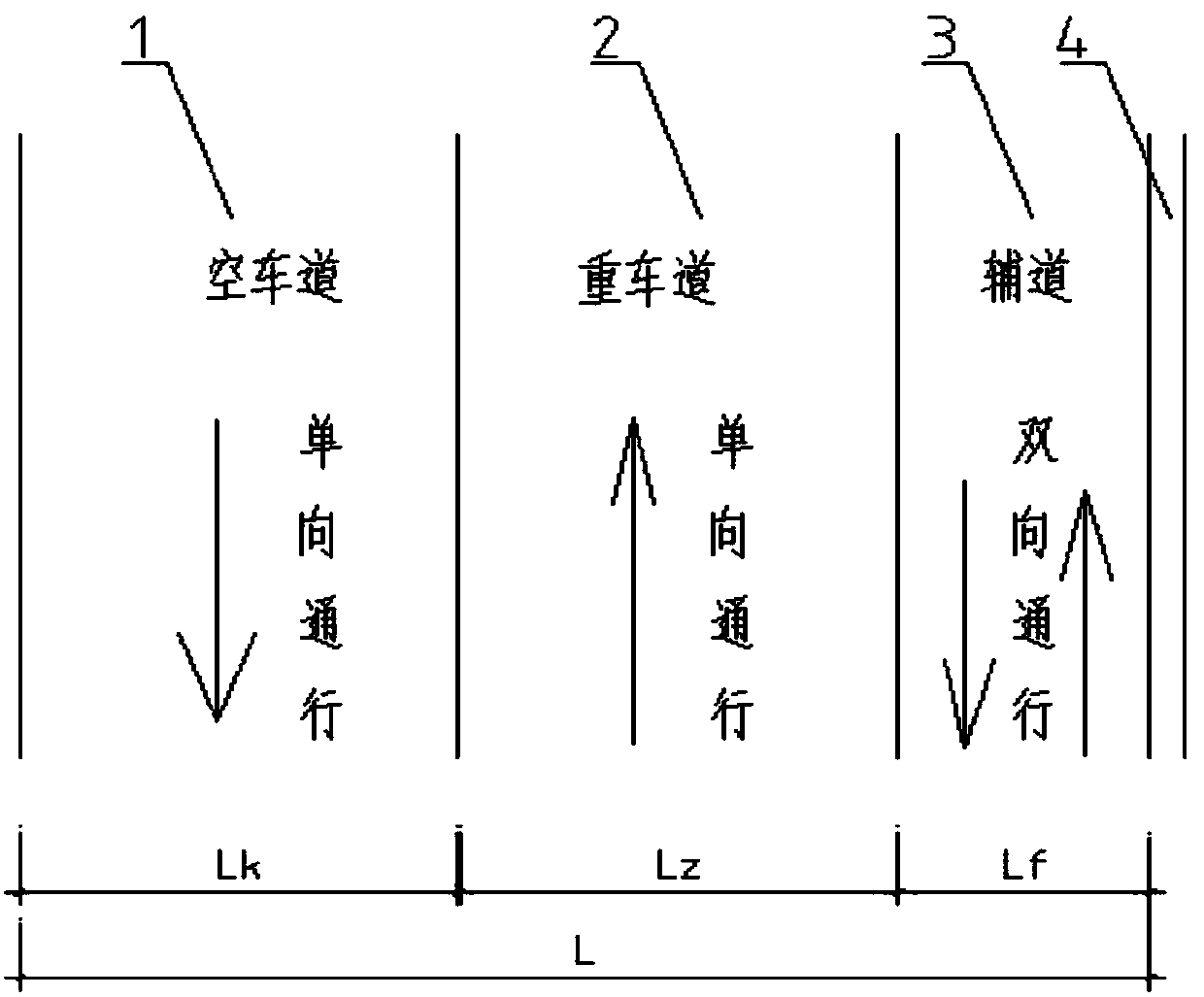

[0023] Determine the pavement width for the empty lane (1) and the heavy lane (2). According to the road design regulations, the clear width of the road surface for large trucks (cargo) is not less than 3.0m. Considering that the speed of vehicles in the site area is generally 5-10 kilometers, and pedestrians do not mix with each other, the value range of the width of the temporary road is within 3m~3.2m is reasonable; secondly, determine the width of the pedestrian auxiliary road (3). The road design stipulates that the clear width of the pedestrian road is not less than the clear width requirement: 0.75~1.0m, and the clear width of the bicycle road is not less than 1.0m. According to the actual situation , the width of pedestrian auxiliary road surface ranges from 1 to 2m, which can be determined according to the number of pedestrians on site and auxiliary transportation.

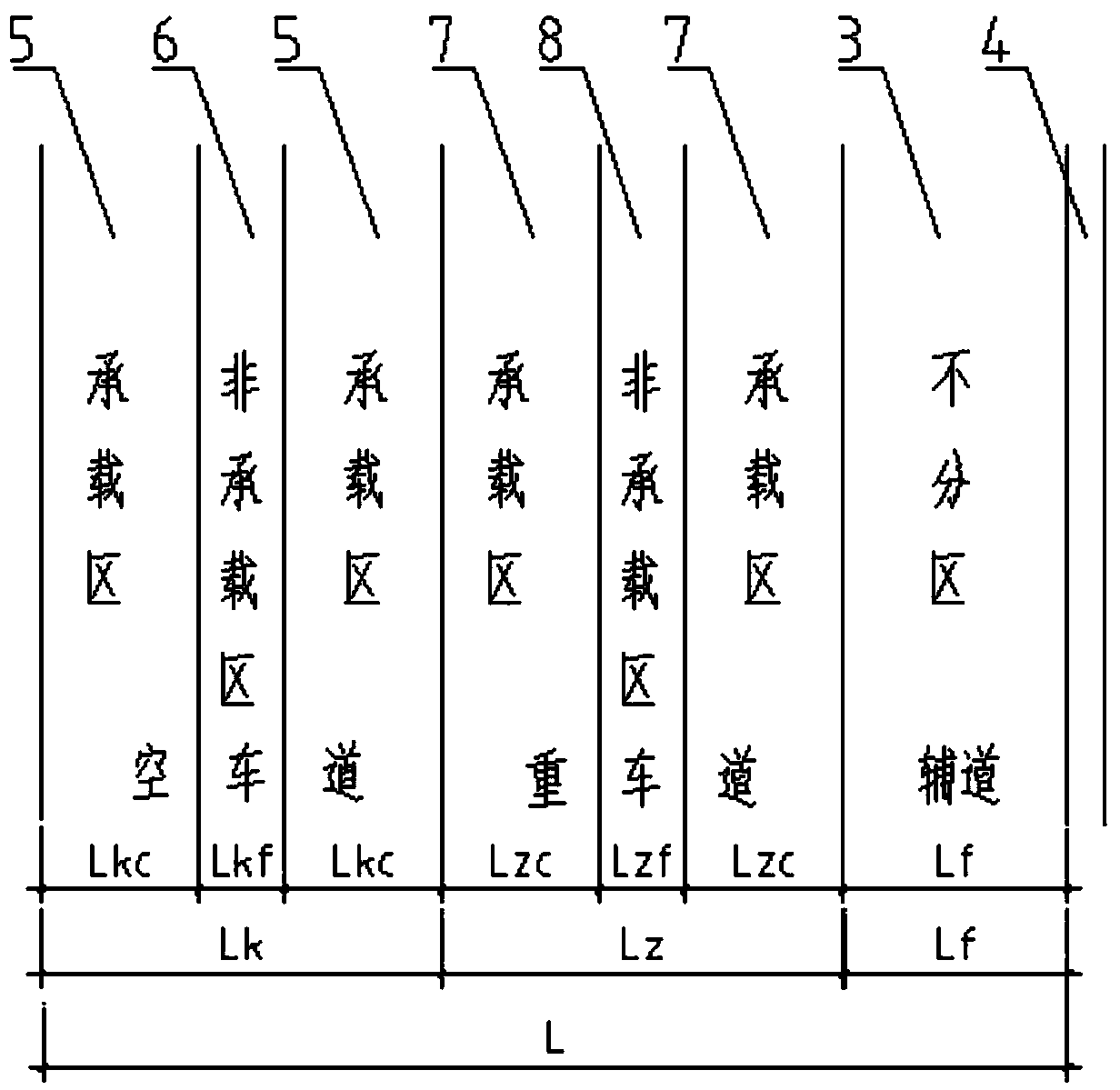

[0024] Determine the empty lane (1) and the heavy lane (2) in the empty lane non-load-bearing area (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com