Non-hinge type auxiliary airbag support

A secondary airbag, hinged technology, applied in the direction of vehicle safety arrangement, pedestrian/occupant safety arrangement, transportation and packaging, etc., can solve the problems of small distance between the secondary airbag and the plastic bracket, failure of the secondary airbag to burst, etc., and achieve good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

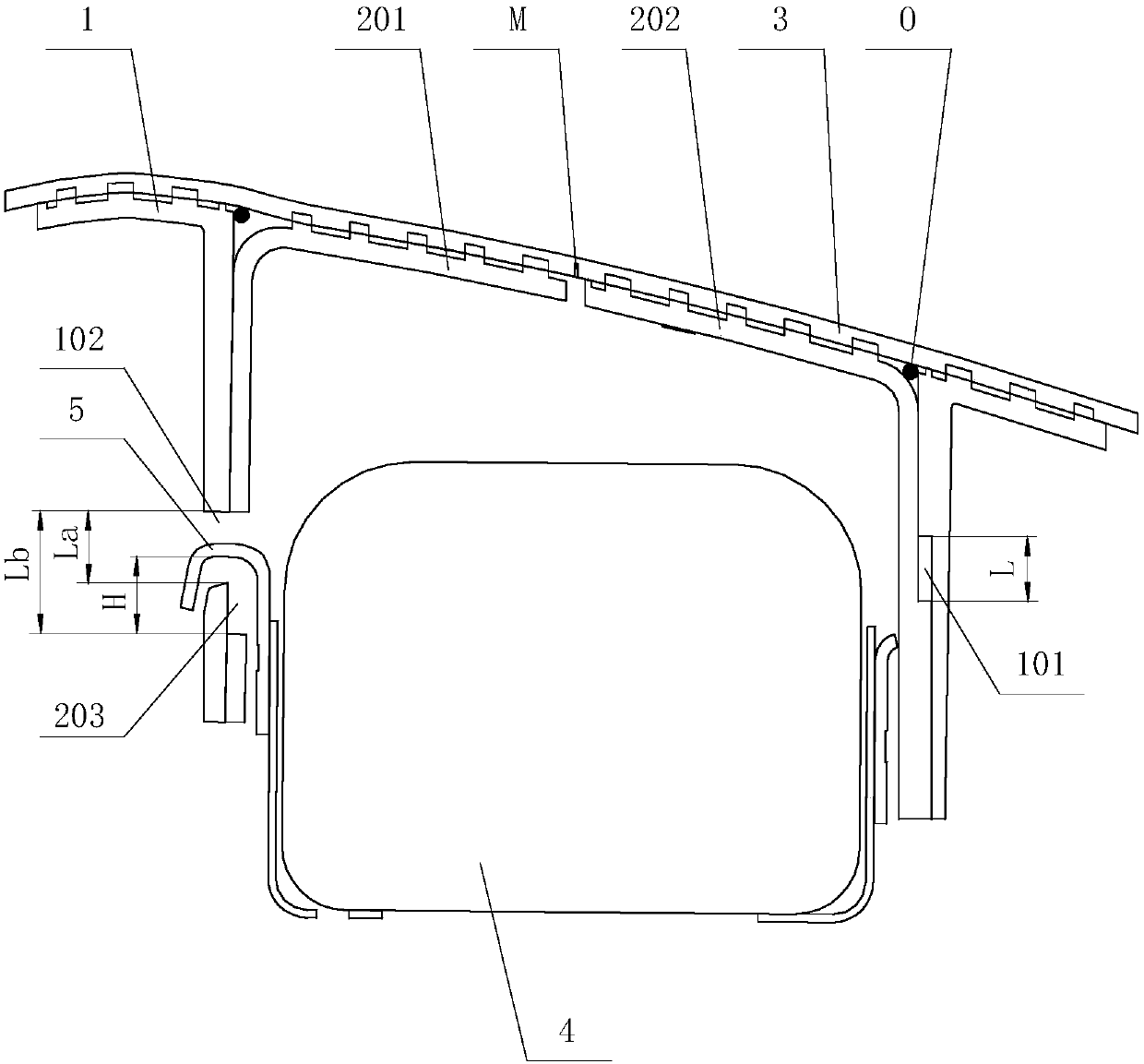

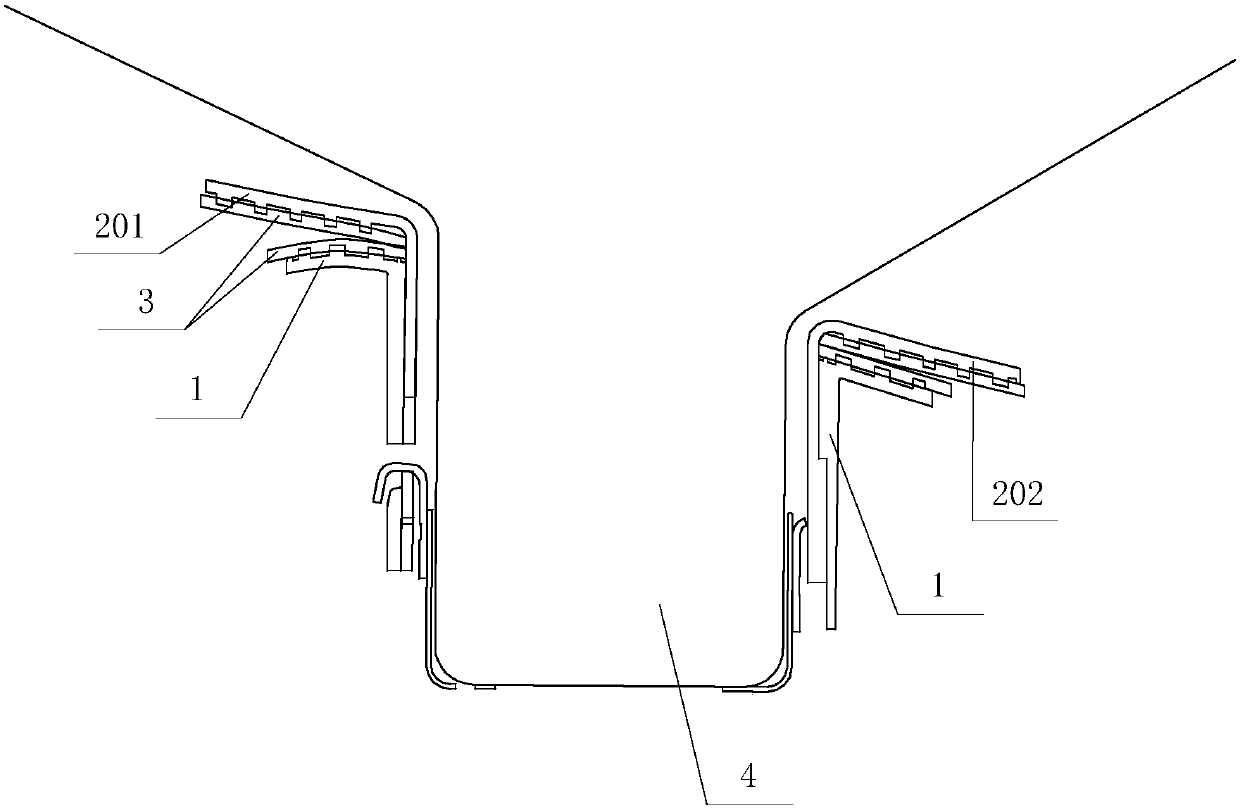

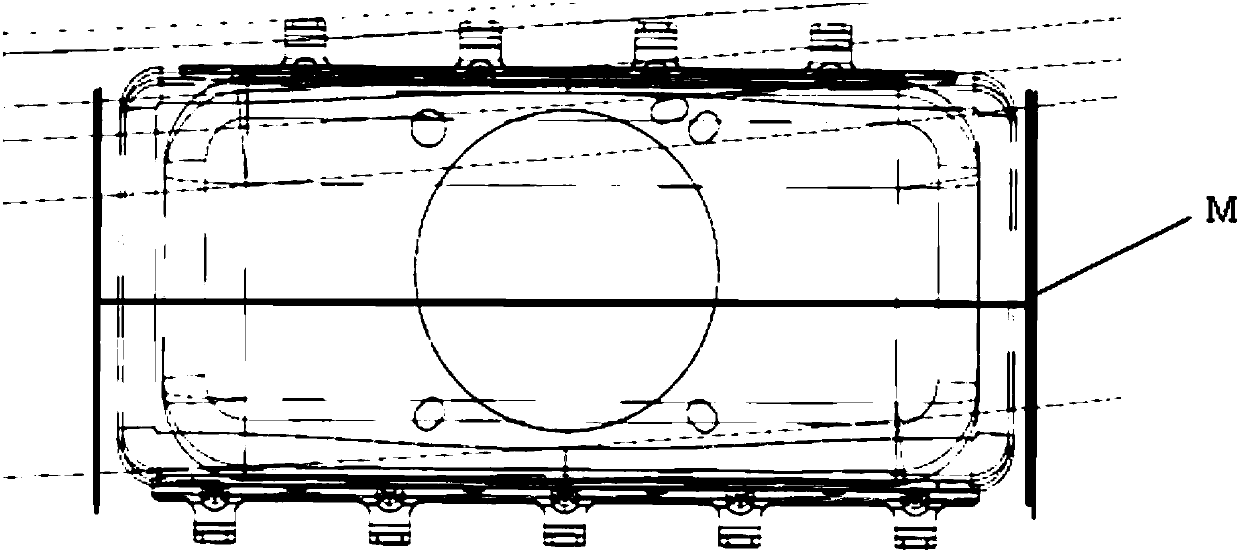

[0029] A non-hinged secondary airbag bracket, comprising a bracket outer frame 1, a flip plate 2 located inside the bracket outer frame 1, the flip plate 2 includes a flip plate I 201, a flip plate II 202, the bracket outer frame 1, flip The outer sides of plate I 201 and turning plate II 202 are connected with IP body 3, and the tear line M of IP body 3 is located between turning plate I 201 and turning plate II 202; the bracket frame 1 passes through turning plate I 201 and turning plate II 202 respectively. The positioning groove 101 is connected, and the positioning groove adopts a dovetail groove, and in the structure of the dovetail groove, the distance between the frame 1 of the bracket and the turning plate I 201 is greater than or equal to the maximum stroke distance required for the upward movement of the turning plate I 201 when it is turned normally; the outer frame of the bracket 1. The distance L from the overturning plate II 202 is greater than or equal to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com