A lead-core type detonating element and a basic detonator composed of the detonating element

A basic detonator and lead core technology, applied in the field of detonating equipment, can solve the problems of the sensitivity of the waste water detonator itself, the difficulty of quality control, and the difficulty of waste water treatment, and achieve the elimination of incomplete explosion, simple production process control, and production process. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

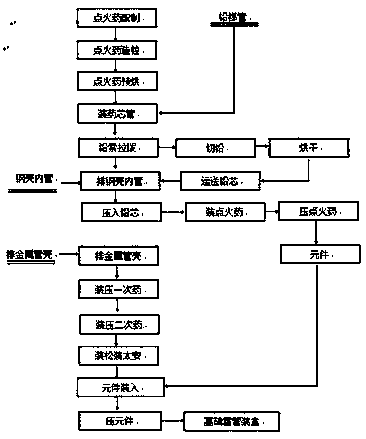

Method used

Image

Examples

Embodiment 1

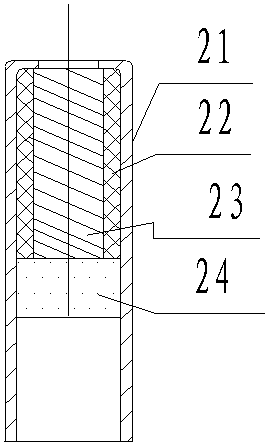

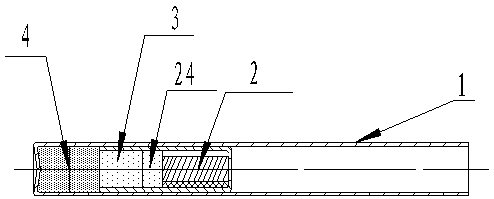

[0025] see figure 1 and figure 2 , a basic detonator without priming charge, comprising a metal shell 1, in which a charge 4, a loose charge 3 and a lead-core type detonating element 2 are sequentially arranged from bottom to top in the metal shell 1, and the lead-core type A delay body is installed above the explosion element 2;

[0026] Wherein, the material of the metal tube shell 1 is steel, copper or aluminum, the tube length is 70 mm, the outer diameter of the metal tube shell is φ7.5 mm, the inner diameter is φ6.5 mm, the bottom of the metal tube shell is flat or concave bottom; the surface of the metal tube shell is Uniform and smooth color, no cracks, no damage;

[0027] The lead-core type deflagration element 2 includes an inner tube 21, a lead core part and a loose-packed propellant 24, wherein the lead core part is located at the inner upper part of the inner tube 21, and the loose-packed propellant 24 is located in the inner tube 21 Below the lead core portion...

Embodiment 2

[0032] In this embodiment, an electronic ignition element is installed above the lead-core type explosive element 2, and the metal shell 1 is made of copper. The high-energy ignition powder or zirconium series ignition powder is composed of zirconium powder, aluminum powder and potassium perchlorate. According to the mass ratio, zirconium powder: aluminum powder: potassium perchlorate=20:15:75; the medicine column is too safe;

Embodiment 3

[0034] In the present embodiment, a nonel is installed on the top of the lead-core type combustion explosion element 2; the material of the metal shell 1 is aluminum; the composition of the high-energy ignition powder is potassium picrate, red lead and potassium perchlorate, in mass ratio, Potassium picrate: red lead: potassium perchlorate = 40:40:20; the drug composition of the drug column is Hexogen;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com