Explosion expansion element specially used for underground blasting engineering

A blasting engineering and component technology, applied in blasting and other directions, can solve the problems of inability to solve the problem of detonation of detonators or explosives, high cost, and hidden safety hazards in blind gun disposal, and achieve excellent detonation performance, reduced compression, and attenuation of blast stress waves. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

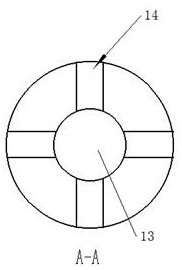

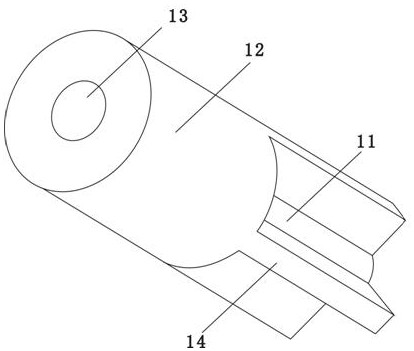

[0031] see Figure 1-5 , a special explosive expansion element for underground blasting engineering, including a fixed block 1, the fixed block 1 is divided into two parts: a fin section 11 and a barrel section 12, the fixed block 1 is provided with a fixed block center hole 13, and the fixed block The central hole 13 penetrates the finned section 11 and the barrel section 12, and the end of the finned section 11 away from the barrel section 12 is closed. The included angle between two adjacent fin blocks 14 is 90°, and the outer periphery of the fin blocks 14 is flush with the outer periphery of the barrel section 12;

[0032] Also includes the expansion and explosion charge column shell 2, the expansion and explosion charge column tube shell 2 is internally pressurized with the expansion and explosion charge column 3, and the expansion and explosion charge column tube shell 2 is located in the finned section of the central hole 13 of the fixed block. 11 bottom; also include...

Embodiment 3

[0041] The number of fins in this embodiment is six, and the included angle of two adjacent fins is 60°, and the rest is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com