Printing component containing unit, printer, ink bottle and ink filling method

An ink bottle and printer technology, applied in printing and other directions, can solve the problems of mixed ink, non-removable, and printer mixed ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

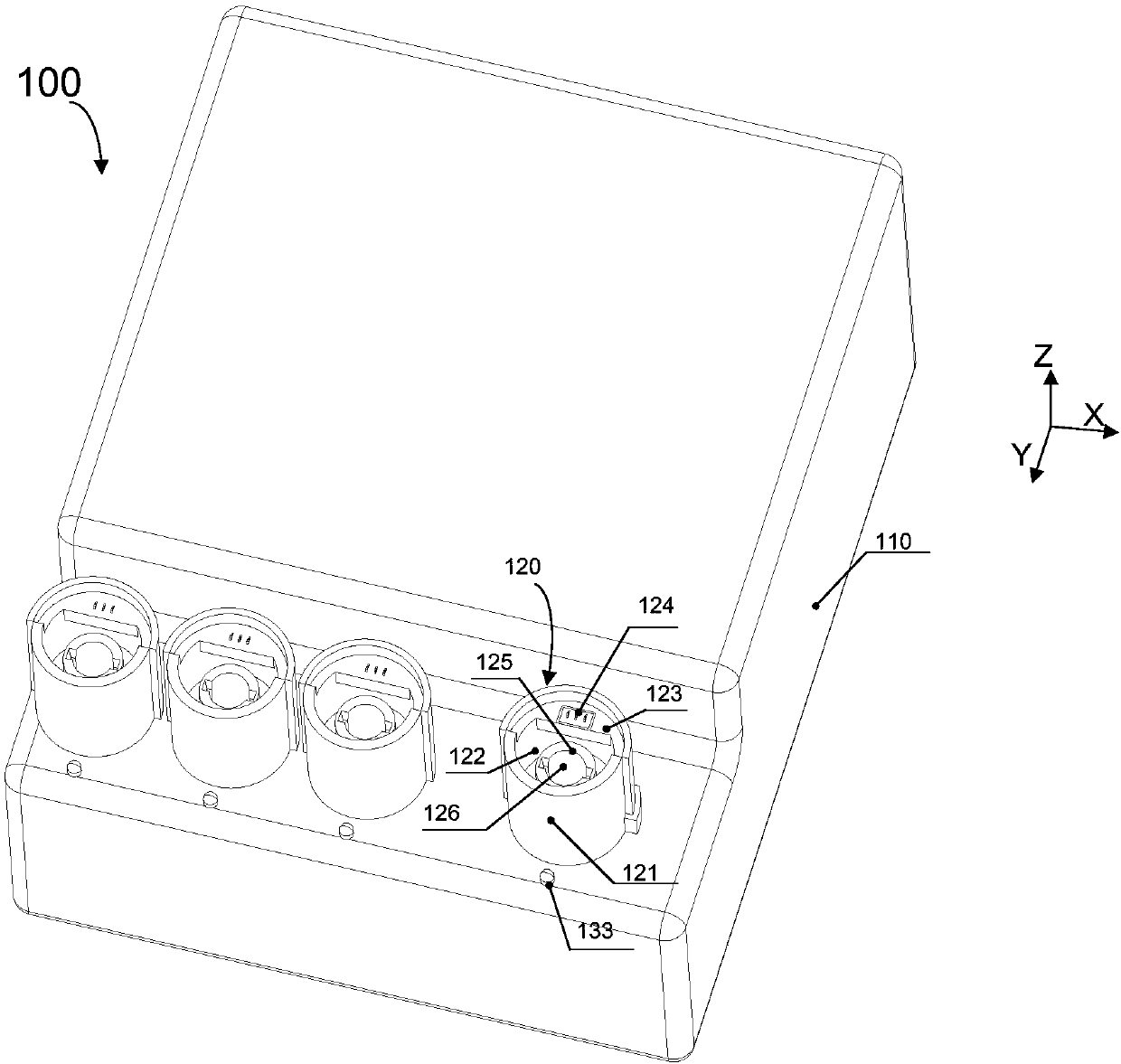

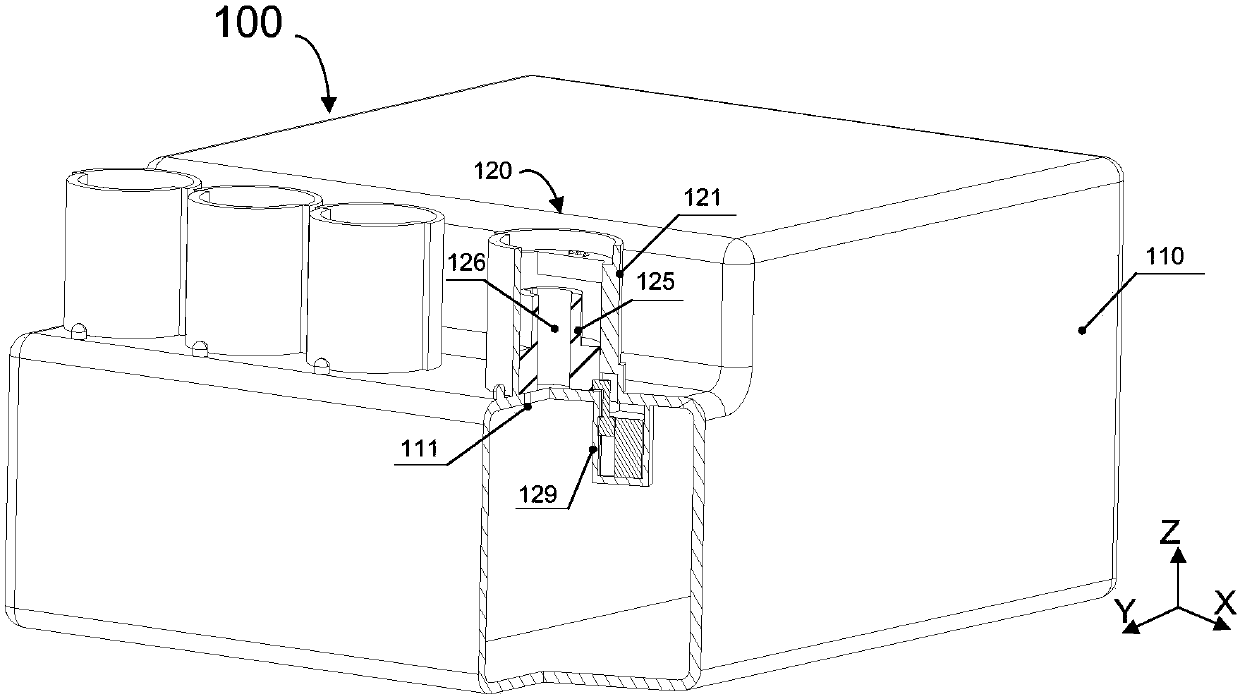

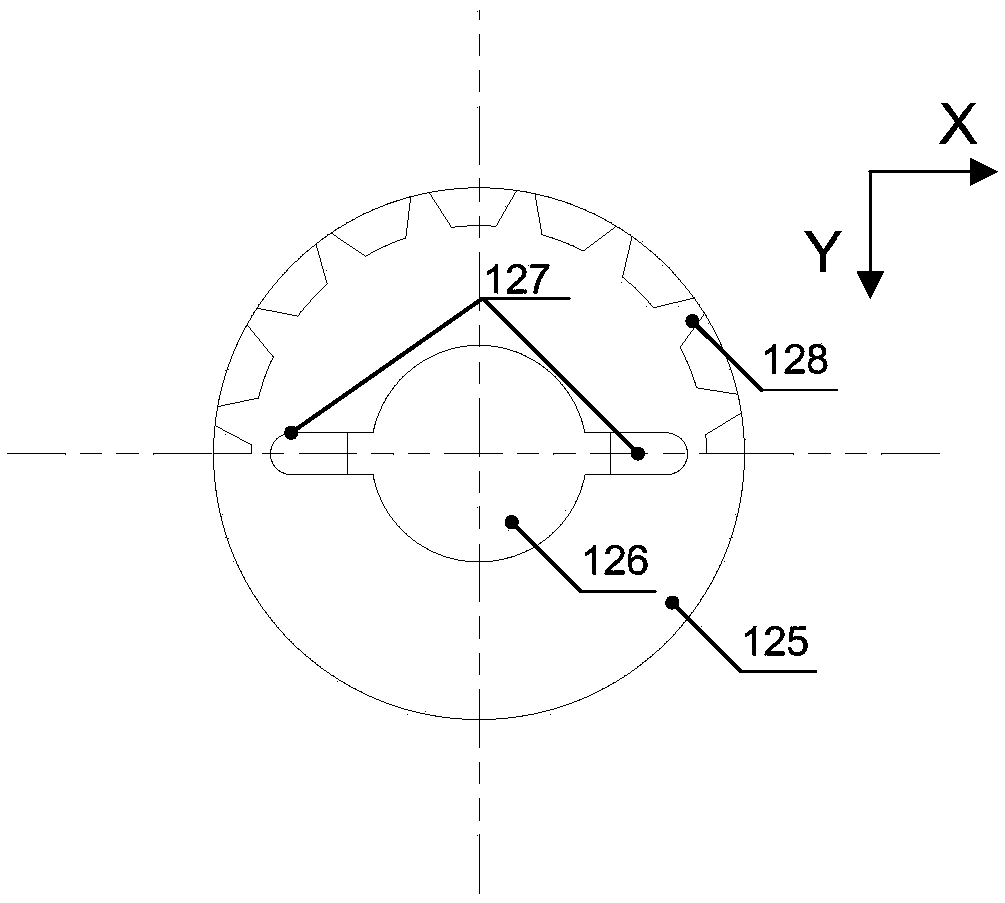

Examples

Embodiment 2

[0068] On the basis of the foregoing embodiment, another sealing portion structure can also be used to switch the open or closed state. Image 6 It is a schematic diagram of the structure of the printing component containing unit provided in the second embodiment of the present invention. Figure 7 It is a schematic diagram of the connection and cooperation between the sealing part and the restricting device provided in the second embodiment of the present invention. Such as Image 6 with Figure 7 As shown, the printing component accommodating unit 200 is substantially the same as the printing component accommodating unit 100 of the first embodiment. The difference is that the sealing part 225 of the second embodiment no longer uses gear meshing connection, but uses the movement between the groove and the elastic member. The assembly relationship can be switched between two different states, which allows the user to adjust the state manually or mechanically.

[0069] specific, F...

Embodiment 3

[0078] In the first and second embodiments above, the information receiving parts used in the printing component accommodating unit are all contact-connected to obtain the ink information of the ink refilling container such as the ink bottle, and if the ink bottle cannot be placed upside down in the printing component accommodating unit It is difficult to ensure reliable contact between the ink bottle and the printing component containing unit when it is at the entrance. Therefore, non-contact scanning technology can be used to obtain ink information. Picture 10 It is a schematic structural diagram of a printing component containing unit provided in the third embodiment of the present invention. Such as Picture 10 As shown, an optical scanner 312 is provided on the printing component accommodating unit, and the optical scanner 312 is electrically connected to the printer controller. Among them, the optical scanner 312 is generally arranged on the front surface of the accommod...

Embodiment 4

[0081] In addition, the present invention also provides an ink bottle, which can be applied to the printer provided in the first or second embodiment, and used in conjunction with the printing component containing unit of the first embodiment. specific, Figure 11A It is a schematic structural diagram of an ink bottle provided in the fourth embodiment of the present invention. Figure 11B It is a schematic structural diagram of the ink bottle with the bottle cap removed provided in the fourth embodiment of the present invention. Such as Figure 11A with Figure 11B As shown, the ink bottle provided in this embodiment includes a bottle body 13, a bottleneck 12, and an information part for identifying ink information in the ink bottle, and the bottleneck includes a refill port 14 for refilling ink.

[0082] Specifically, the ink bottle is generally cylindrical, and in addition to the bottle body 13 and the bottleneck 12, it also includes a bottle cap 11 and the like. The bottleneck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com