High power drainage pump-used motor

A technology for drainage pumps and motors, which is applied in the field of motors for drainage pumps and high-power drainage pumps. It can solve the problems of reducing the idling stroke of the starting rib, burning the motor, and small idling strokes, so as to solve the difficulty of starting and avoid starting. Effects of noise and starting voltage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

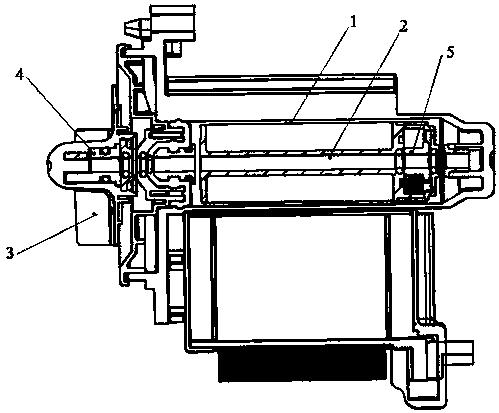

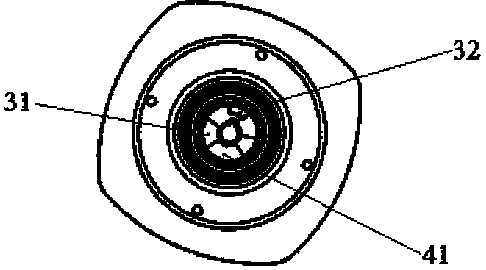

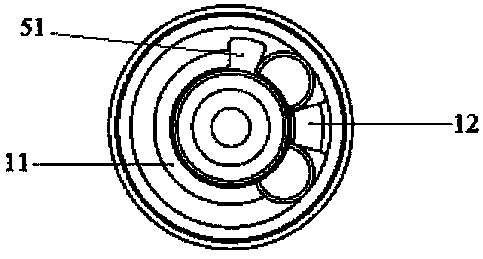

[0021] The structural schematic diagram of the specific embodiment of the present invention is as follows Figure 1-3 As shown, the motor for the high-power drainage pump includes a permanent magnet rotor 1, a motor shaft 2 and an impeller 3, an impeller coupling 4 is fixed on the motor shaft 2, and the impeller coupling 4 is activated by the impeller coupling 4. Rib 41, there is an impeller housing cavity 31 in the center of the impeller 3, which is used to accommodate the impeller coupling 4. The inner side wall of the impeller housing cavity 31 protrudes with an impeller limiting rib 32, and the impeller coupling starts the rib 41 to rotate forward or reverse. After turning a certain distance, it interferes with the impeller limiting rib 32; a rotor coupling 5 is also fixed on the motor shaft 2, and there is a rotor coupling starting rib 51 on the rotor coupling 5, and the permanent magnet rotor The magnetic core of 1 has a magnetic core accommodation cavity 11 for accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com