Vacuum isolating load switch

A load switch, vacuum isolation technology, applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as causing danger, breakdown, and the insulation distance of the isolation knife does not reach a safe value, so as to ensure safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

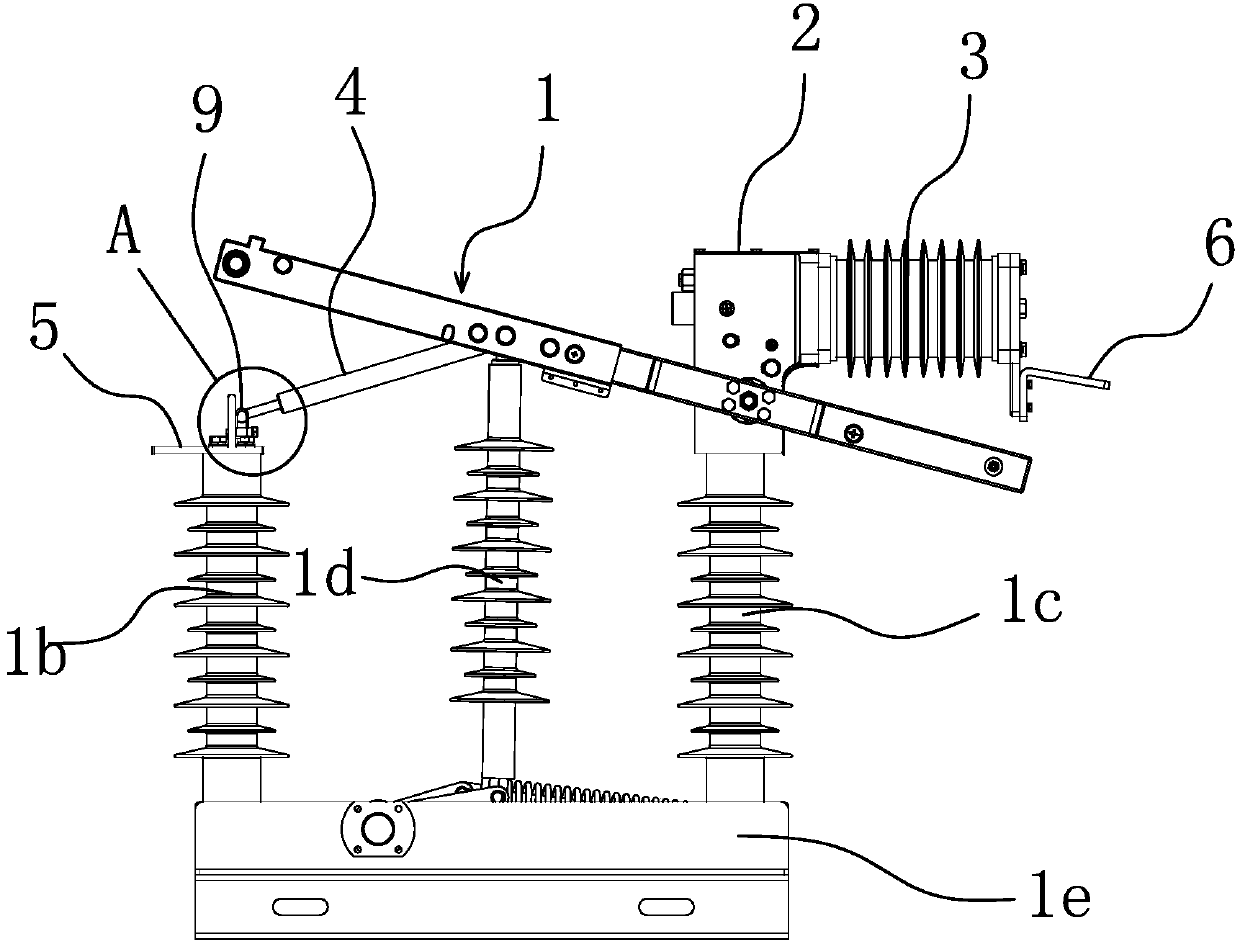

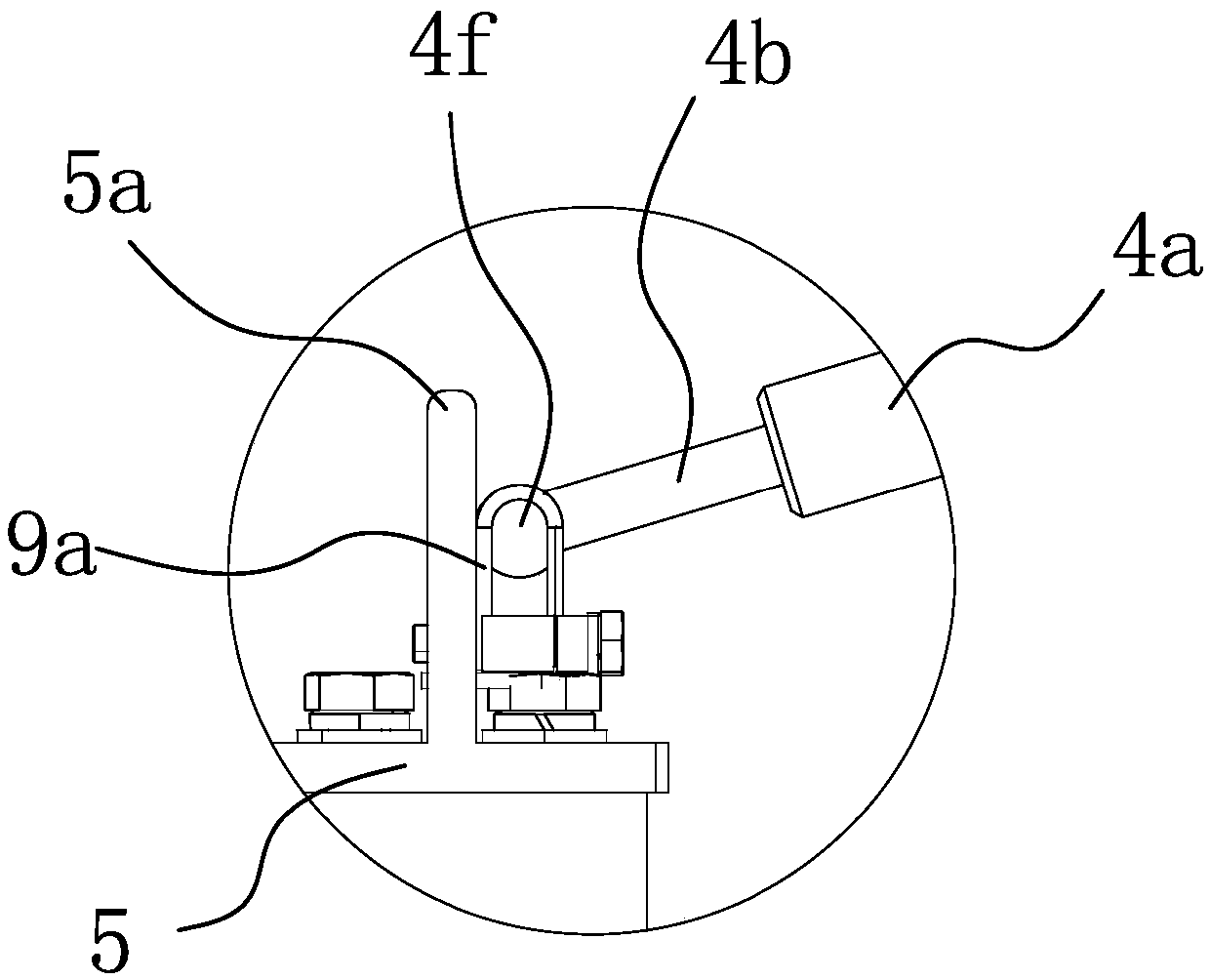

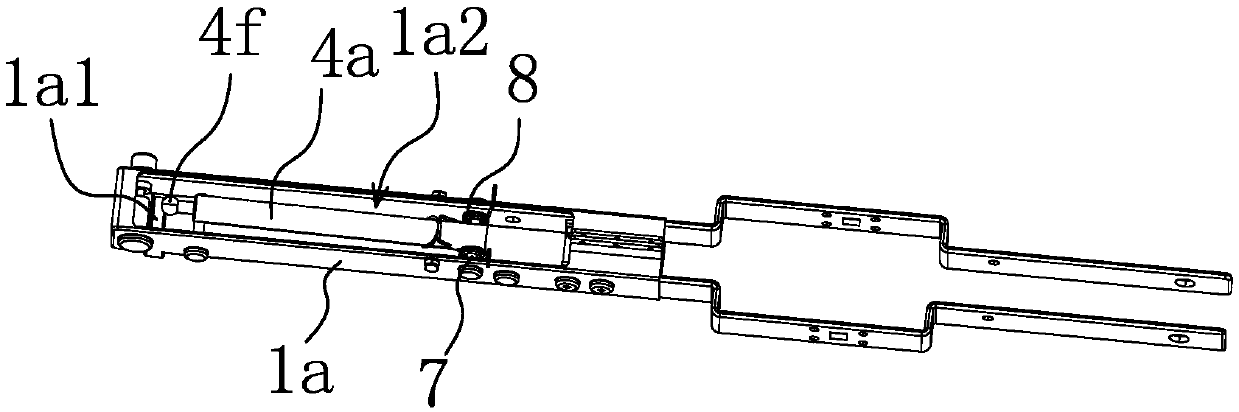

[0030] Such as figure 1 As shown, the vacuum isolation load switch includes several sets of isolating knife assemblies 1, and each set of isolating knife assemblies 1 includes an isolating knife 1a, a first insulating post 1b, a second insulating post 1c, an insulating push rod 1d and a base 1e. The isolation knife assembly 1 is connected with an arc extinguishing chamber fast arc extinguishing transmission chain mechanism 2 and an arc extinguishing chamber 3 . The first insulating support 1b, the second insulating support 1c and the insulating push rod 1d are all installed on the base 1e, wherein the top of the first insulating support 1b is fixedly connected with the input wiring board 5, and the input wiring board 5 protrudes upwards to form a contact 5a The first end of the isolation knife 1a is provided with a contact groove 1a1 that can touch and connect with the contact 5a. The second end is hinged on the arc extinguishing chamber fast arc extinguishing transmission ch...

Embodiment 2

[0038] Such as Figure 8 As shown, in this embodiment, the structure of the vacuum isolation load switch is basically the same as that of Embodiment 1, the difference is that: the lever assembly 2h includes a lever body 2h5, and the upper part of the lever body 2h5 is on the two sides of the opening roller 2d. end, the middle part of the crank arm body 2h5 is hinged on the crank arm shaft 2i, the side wall of the lower part of the crank arm body 2h5 abuts against the outer edge of the cam 2g, and the limit notch 2g1 on the cam 2g is a concave arc-shaped notch, The end surface of the lower part of the crank arm body 2h5 is an arc surface, and when the isolation knife 1a rotates to a preset angle, the arc surface can be embedded in the arc-shaped notch and form a fit with the arc-shaped notch.

Embodiment 3

[0040] In this embodiment, the structure of the vacuum isolating load switch is basically the same as that of Embodiment 1, the difference is that the first end of the arc striker 4 is a plug, and the top of the first insulating support 1b is provided with a socket, and the plug and the socket are tightly fitted. , and when the pulling force received by the first end of the arc striking rod 4 exceeds the pressing force of the socket on the plug, the plug can come out of the socket. The connection and disconnection between the arc striker 4 and the first insulating support 1b are very convenient and quick by adopting the plug and the socket.

[0041]The working principle of the vacuum isolation load switch of the present invention is as follows: by operating the rotation angle of the isolation knife 1a, the arc extinguishing chamber can be opened and closed. The position starts to rotate around the top of the second insulating support 1c, and the first end of the isolation knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com