A packing force calculation method for diesel engine aftertreatment

A calculation method and packaging force technology, which is applied in the field of diesel engine exhaust post-processor, can solve the problems of incomplete calculation of packaging force, etc., and achieve the effect of improving calculation accuracy and good calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

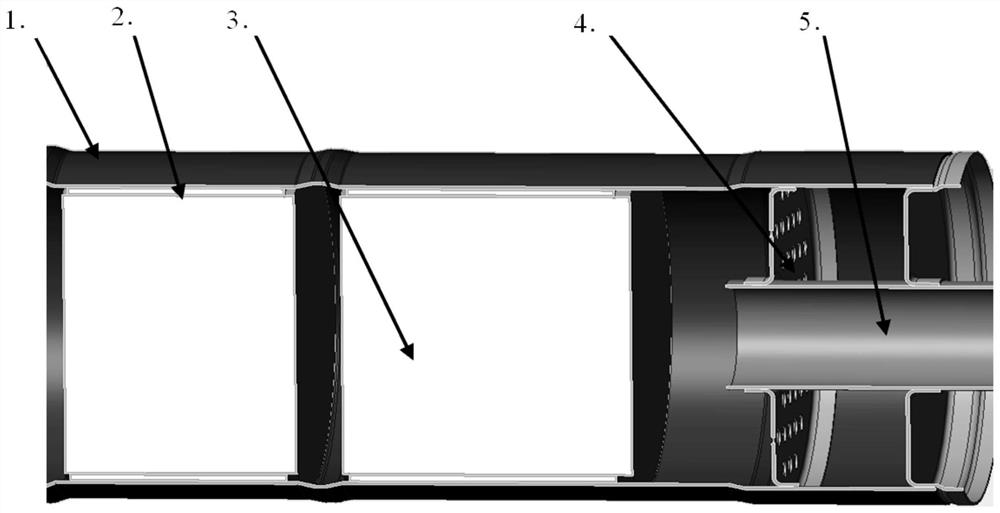

[0030] This embodiment provides a method for calculating the encapsulation force for aftertreatment of diesel engines, and the calculation method is applied to such as figure 1 The diesel engine post-treatment package structure includes a package cylinder 1 ; a liner 2 ; a catalyst carrier 3 ; a muffler porous plate 4 ; and an exhaust tailpipe 5 . The calculation method, such as Figure 5 ,include:

[0031] Step 1, measure and obtain the pad parameters, and the pad parameters are pad body density;

[0032] Step 2, measuring the first functional relationship between the gasket parameters and the peak pressure during packaging, and the second functional relationship between the test gasket parameters and the rebound pressure after packaging;

[0033] Step 3. Calculate the encapsulation force p according to the required post-encapsulation springback pressure.

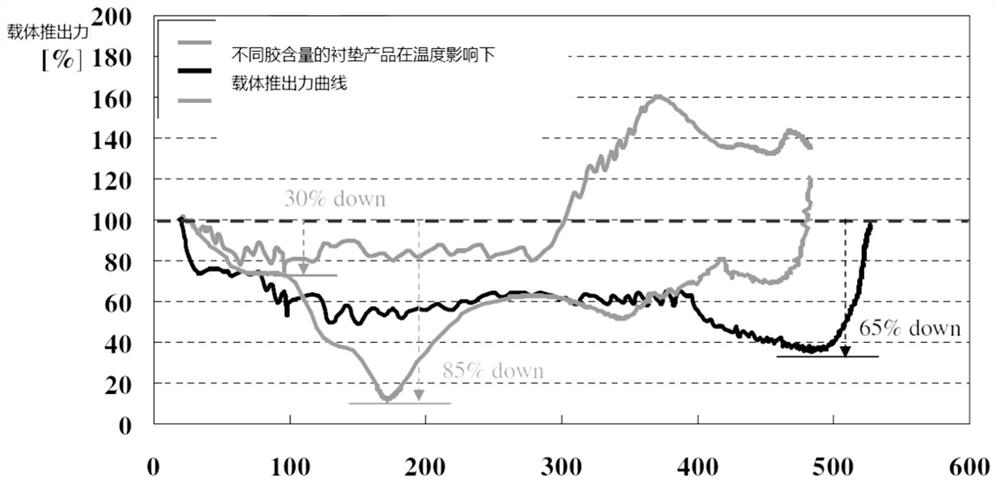

[0034] Specifically, firstly, it is determined through experiments that image 3 Schematic diagram of the function r...

Embodiment 2

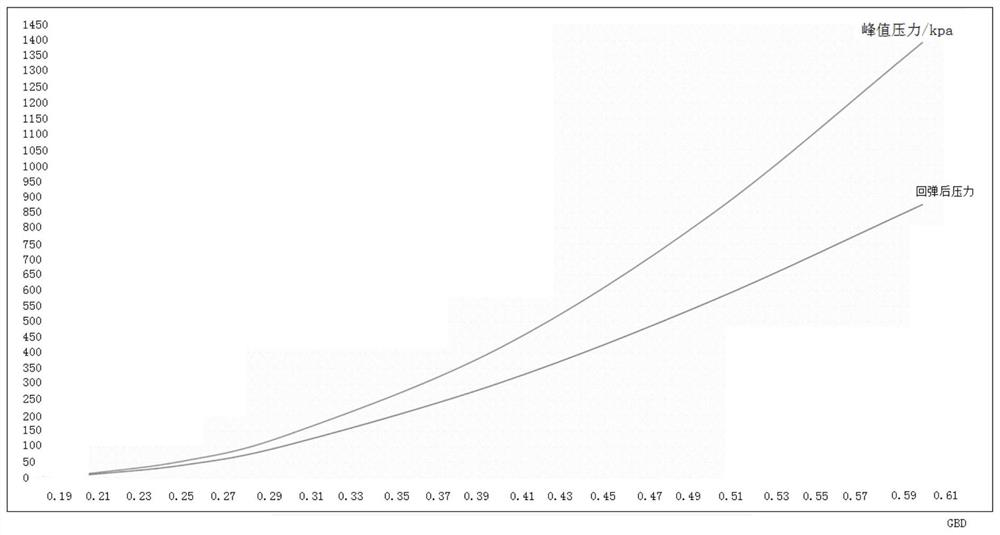

[0037] On the basis of Embodiment 1, this embodiment further simplifies the calculation process. By selecting 6 points as the reference points of functional relationship 1 and functional relationship 2. Take the GBD of the 6 reference points as the value of the x-axis, and measure the corresponding attenuation and holding force curve after packaging. The measurement results are shown in Table 1:

[0038]

[0039] According to Table 1, according to the difference fitting method to get Figure 4 . Similarly, the peak pressure is used to assess the reliability of the packaging process in the general design; the pressure value after the springback obtained after the test can be used in the last step of the design: the reverse determination of the GBD value, which is directly used to design the diameter of the package shell.

[0040] Embodiment 2 provides a calculation of packaging force in the packaging reliability design in the general design that does not require high preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com