Mounting method of water taking siphonage pipelines of inland lakes

A technology of siphon pipeline and installation method, which is applied in the direction of pipeline laying and maintenance, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem that the construction method of siphon pipeline is not suitable for inland lakes, etc., and achieves easy operation and high cost savings. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

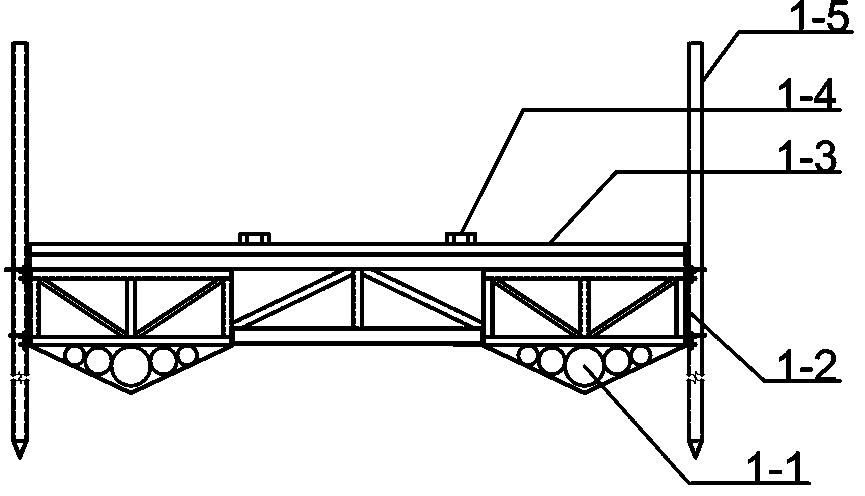

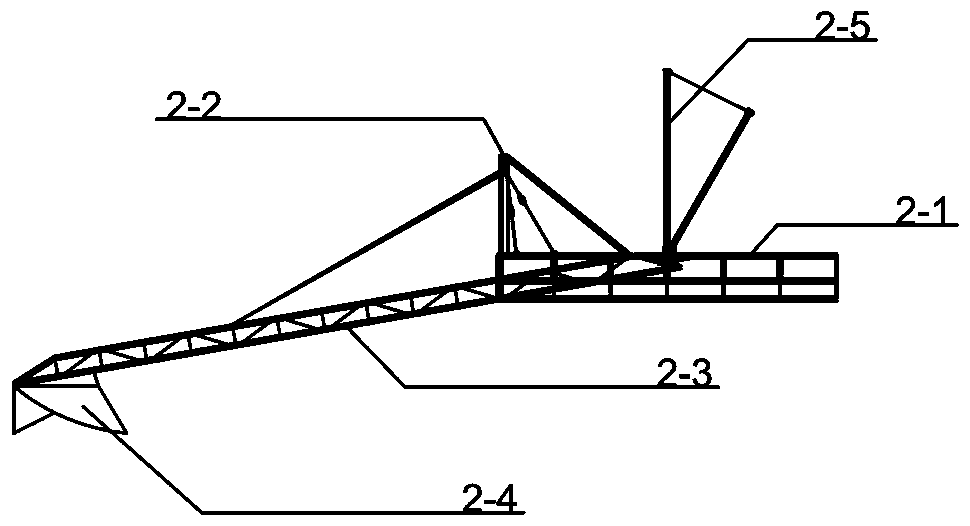

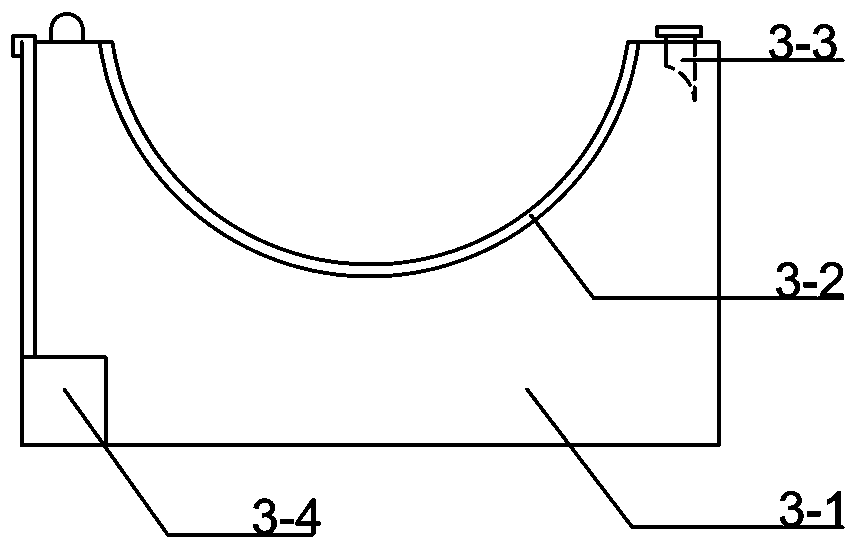

[0023] Embodiment 1: This embodiment is applicable to the installation of siphon pipelines for water intake in inland lakes. The specific method is: make a siphon pipeline construction work platform on a land platform, put the siphon pipeline construction work platform into the water with a crane, and perform work for the siphon pipeline construction. Set up the power system on the platform; drive the excavator to the floating platform of the conjoined structure and fix it; use the power system on the floating platform and the telescopic arm of the excavator to move the platform to the design position of the water intake head to confirm that the axis position is correct, and then fix the support Put down the support on the seabed; the excavator starts to excavate the pipe trench, and the order of excavating the pipe trench is first deep and then shallow; after the submarine pipe trench excavation is completed, move the floating platform to the shore and transfer it away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com