an electric brake

A brake, electric technology, applied in the direction of brake, brake type, axial brake, etc., can solve the problems of wear, short service life, complex structure, etc., to achieve high control accuracy, simplify the structure, and ensure the effect of braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

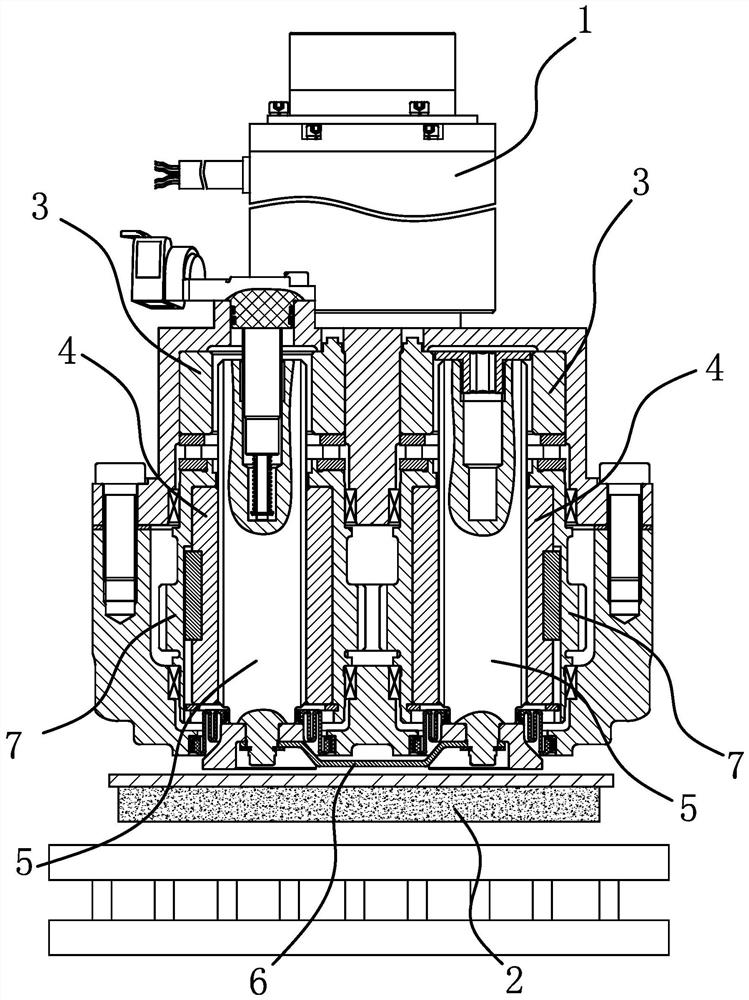

[0030] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

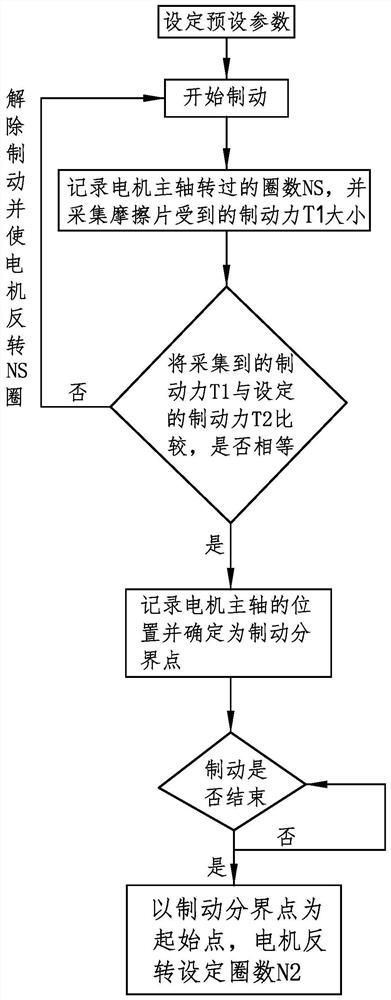

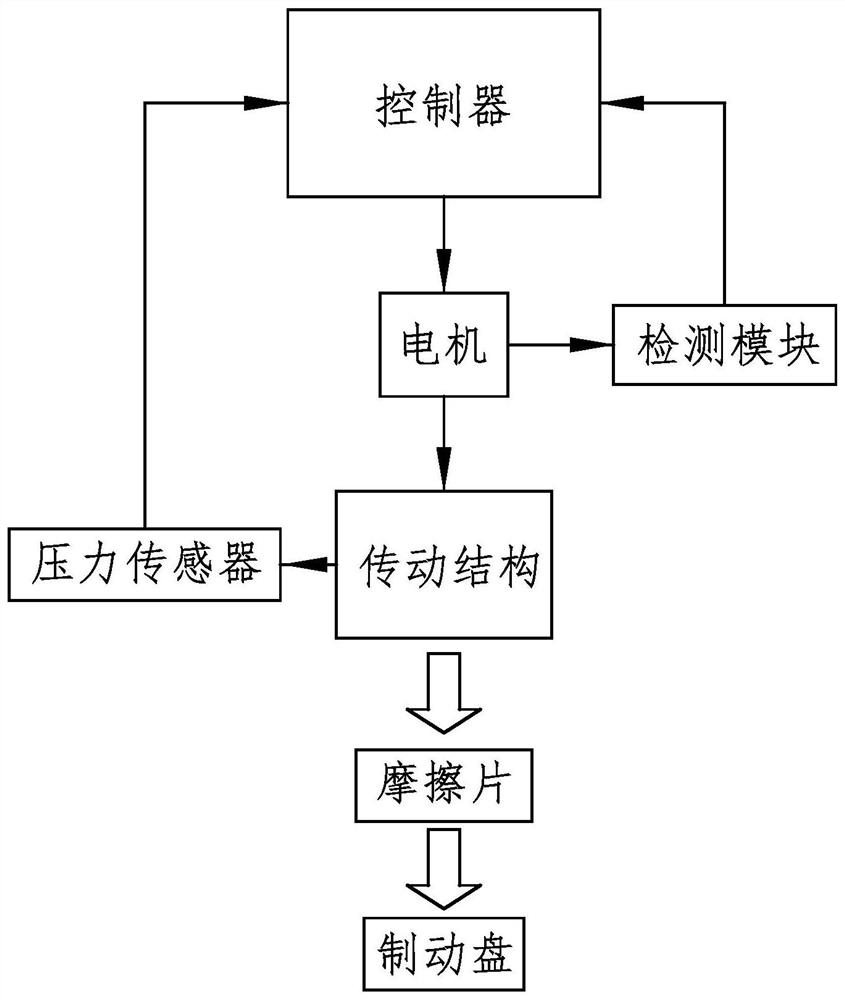

[0031] Such as image 3 As shown, the electric brake includes a drive motor 1, a screw drive structure, and a friction plate 2. The screw drive structure includes a transmission gear, a nut 4, a screw 5 threadedly connected to the nut 4, and a limit member 6, and the nut 4 is connected to the The output end of the driving motor 1 is in transmission connection, the limiting member 6 can limit the screw 5 in a circumferential direction, and one end of the screw 5 faces the friction plate 2. In this embodiment, both the nut 4 and the screw 5 are two. The outer sides of the two nuts 4 are both fixed with a ring gear 7 that can be connected to the transmission gear. The limit member 6 is plate-shaped and has two non-circular The cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com