Hinge with seven pivots

A hinge and seven-axis technology, applied in the field of seven-axis hinges, can solve problems such as increased cost, poor clamping processing, and high product incidence, and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

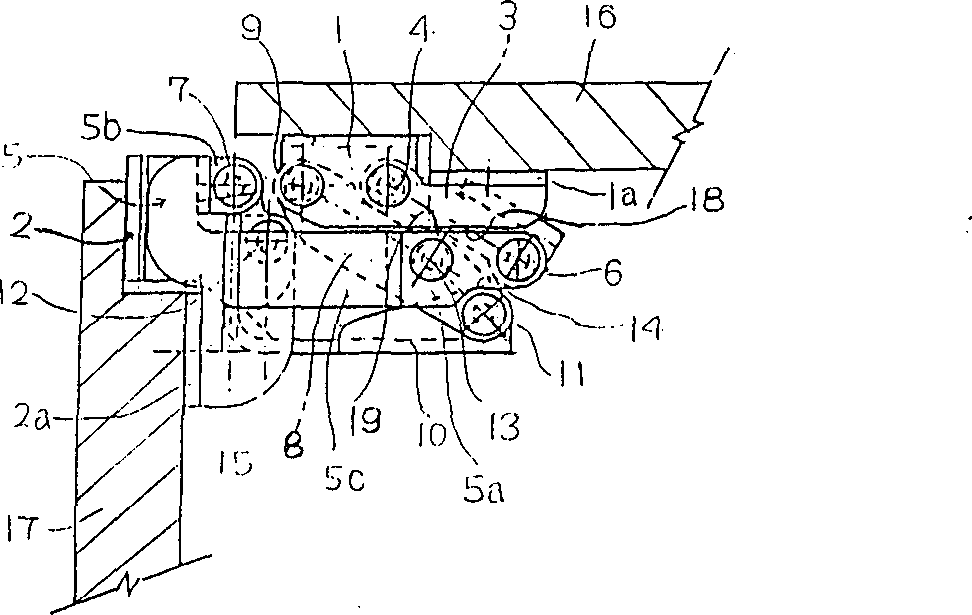

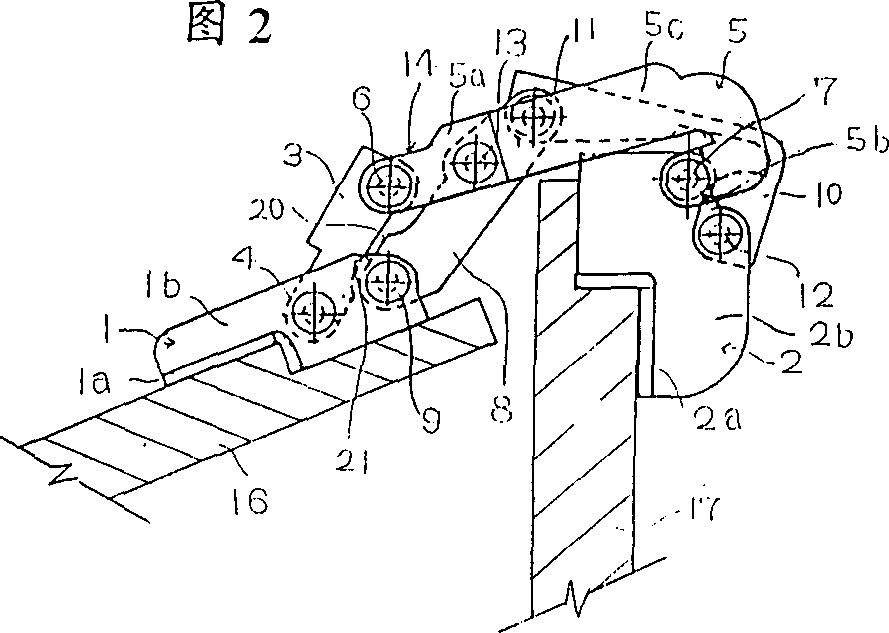

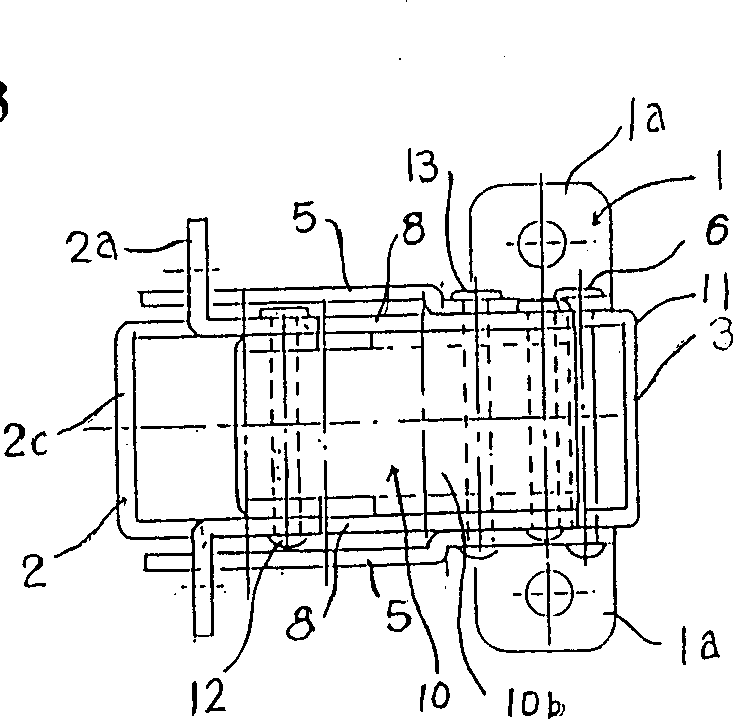

[0013] Hereby use the reference symbols in the accompanying drawings to explain as follows: the seven-axis hinge of the present invention has a first rotating member 1 and a second rotating member 2 that are arranged to be rotatable relative to each other, and the first rotating member is pivotally connected with the first pivot 4. The base end of the component 1 and the first connecting rod 3 is pivotally connected to the front end of the first connecting rod 3 and the base end of the second connecting rod 5 by the second pivot 6, and the second connecting rod is pivotally connected by the third pivot 7 The front end of 5 and the second rotating member 2 are pivotally connected to the base end of the first rotating member 1 and the third connecting rod 8 by the fourth pivot 9 at a position away from the first pivot 4, and pivotally connected by the fifth pivot 11 The front end of the third connecting rod 8 and the base end of the fourth connecting rod 10 pivotally connect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com