Cutting tabletop of large stone cutting machine

A cutting machine and countertop technology, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of inability to cut, low production cost, inconvenience, etc., and achieve the effect of saving useful work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

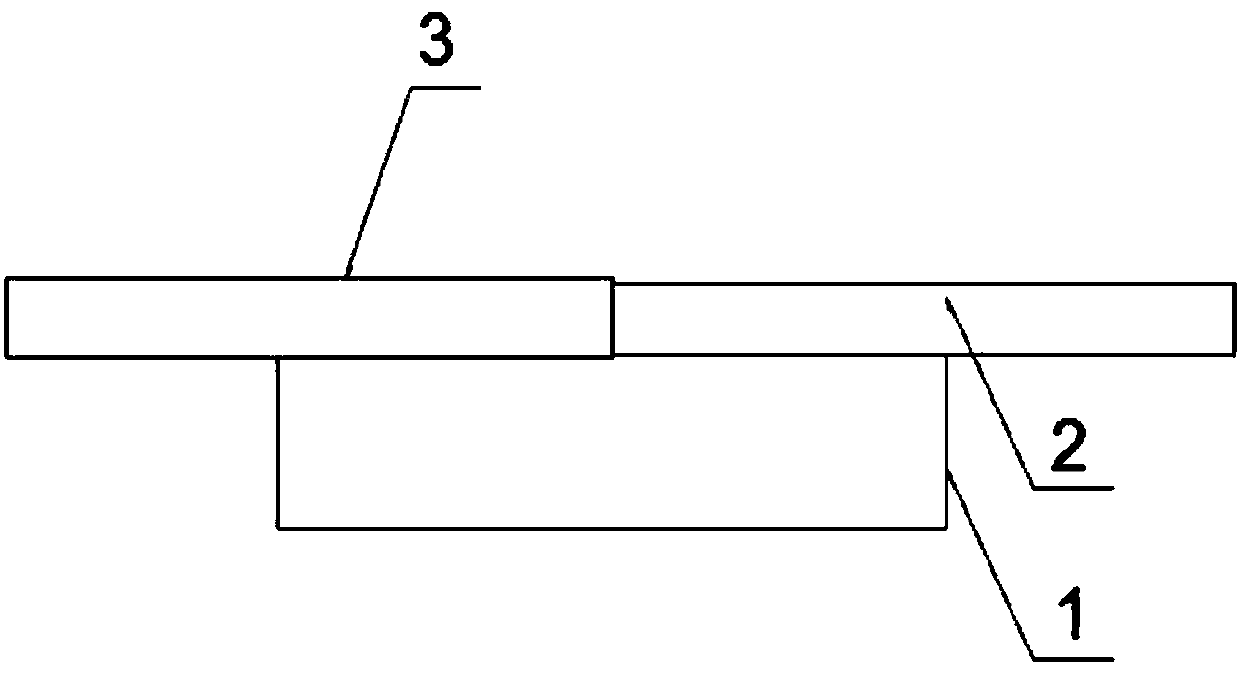

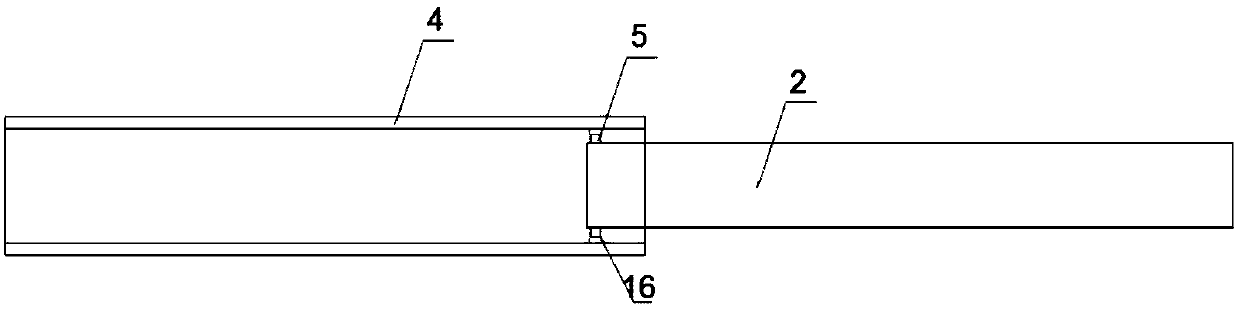

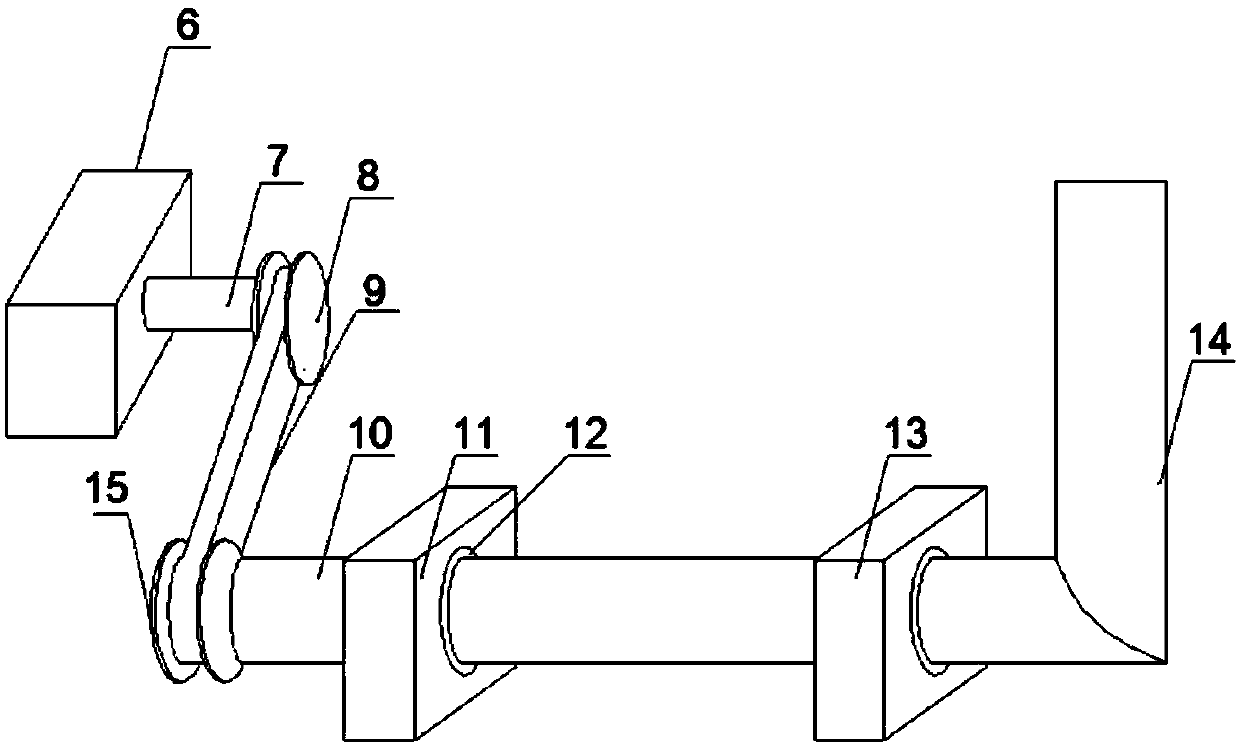

[0029] A large stone cutting machine cutting table, including a pillar 1, the surface of the pillar 1 is provided with a fixed table 3 and a movable table 2, one end of the movable table 2 is provided with a fixed rod 5, the top of the fixed rod 5 is provided with a pulley 16, and the fixed table is provided with a pulley 16. The inner wall of 3 is provided with a chute 4, one end of the chute 4 is provided with a limit plate 41, the pillar 1 is a hollow structure, the interior of the pillar 1 is provided with a servo motor 6, and one end of the servo motor 6 is provided with a transmission rod 7, the transmission rod 7 A roller 8 is provided on the surface of the roller 8, and a timing belt 9 is provided on the surface of the roller 8. One end of the timing belt 9 is connected to the screw fixing end 15, and the screw fixing end 15 is provided with a screw rod 10 inside. and the second bracket 13, one end of the screw 10 is provided with a support rod 14, when the movable tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com