Tandem chemical feeding device

A dosing device and serial technology, applied in the field of serial dosing devices, can solve problems such as ineffective removal, slow dissolution rate, difficulty in potion, etc., and achieve the effect of improving mixing and dissolving efficiency and solubility, and increasing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

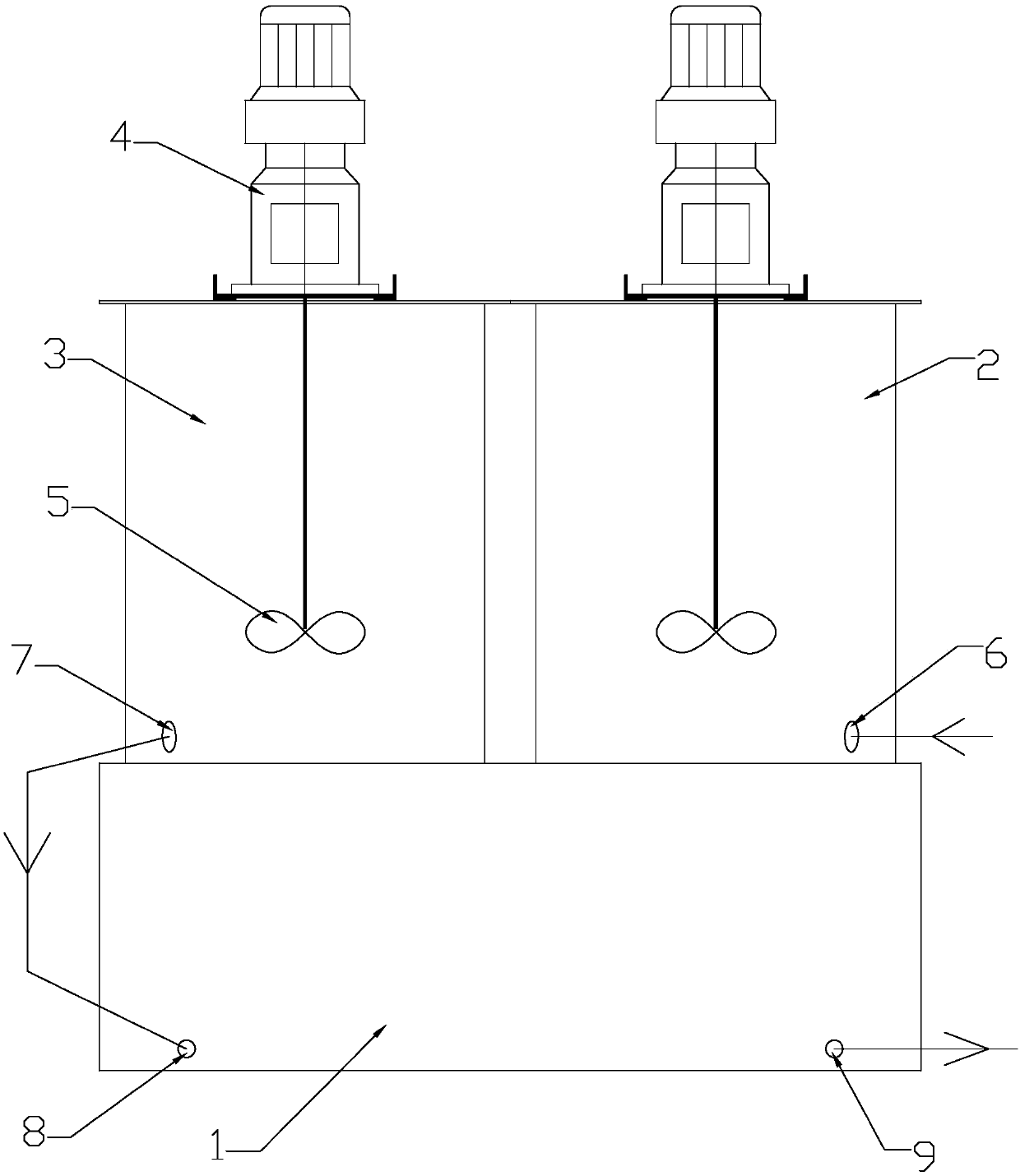

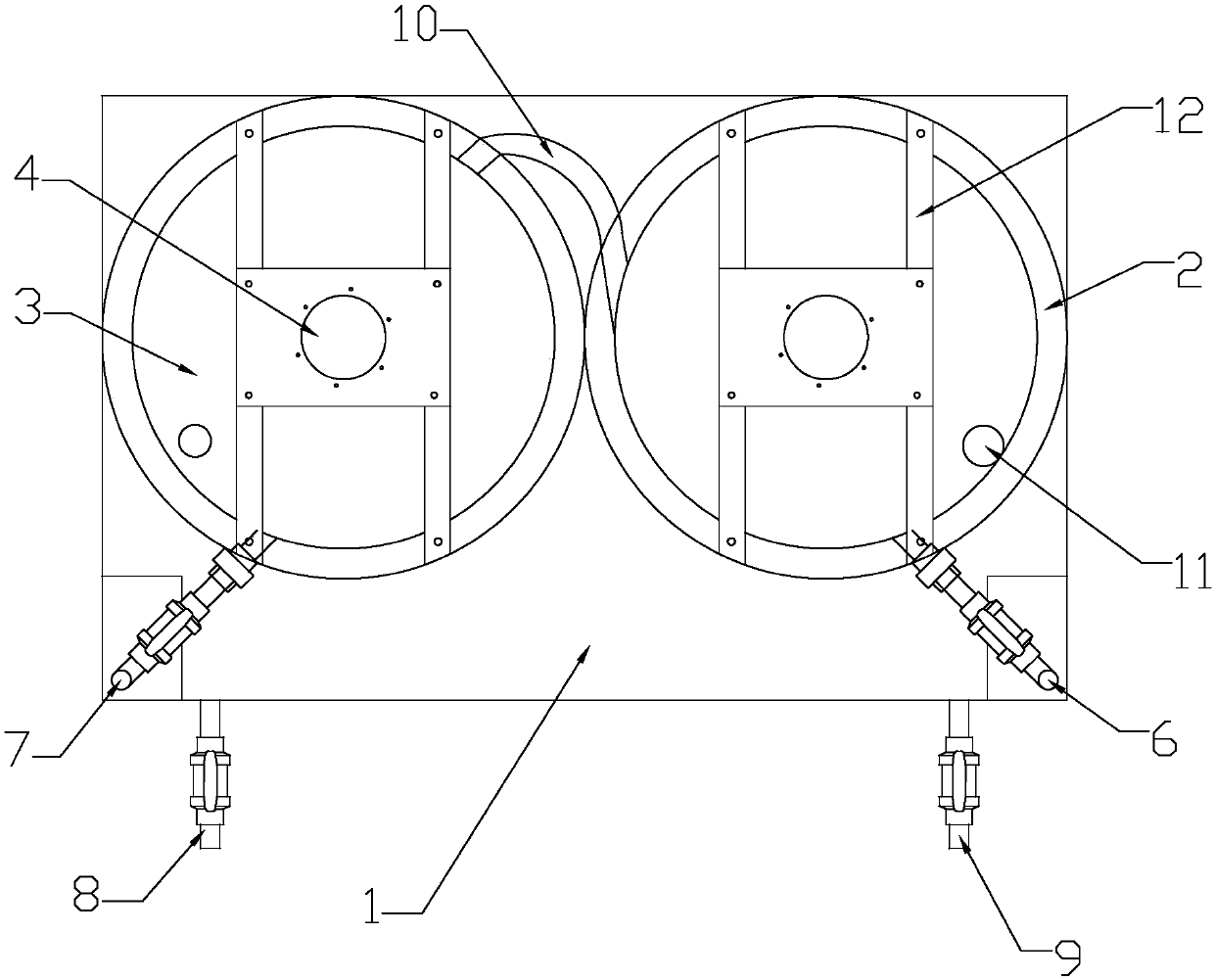

[0010] Such as figure 1 figure 2 As shown, the tandem dosing device includes a cuboid liquid storage chamber 1 and two vertical first tank body 2 and second tank body 3 installed above the liquid storage chamber 1, the first tank body 2 and the second tank body The top of the tank body 3 is vertically provided with a variable speed motor 4, respectively, and each tank body is vertically provided with a stirring blade 5 which can rotate freely. 2. A water inlet 6 is provided on one side of the bottom, and a water outlet 7 is provided on one side of the bottom of the second tank body 3. The water outlet 7 communicates with the water inlet 8 of the liquid storage chamber 1 below through a pipe, and one side of the liquid storage chamber 1 is opened. There is a drain port 9, the first tank body 2 and the second tank body 3 communicate through a curved connecting pipe 10, and the tops of the first tank body 2 and the second tank body 3 are respectively provided with a dosing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com