Digitally-controlled active IGBT driving circuit

A driving circuit and circuit technology, applied in the direction of electrical components, electronic switches, pulse technology, etc., can solve the problems of high power loss, junction temperature rise, and active clamping technology that cannot meet the needs of use, so as to ensure stable operation and suppress Effect of shutting down voltage spikes and avoiding catastrophic consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

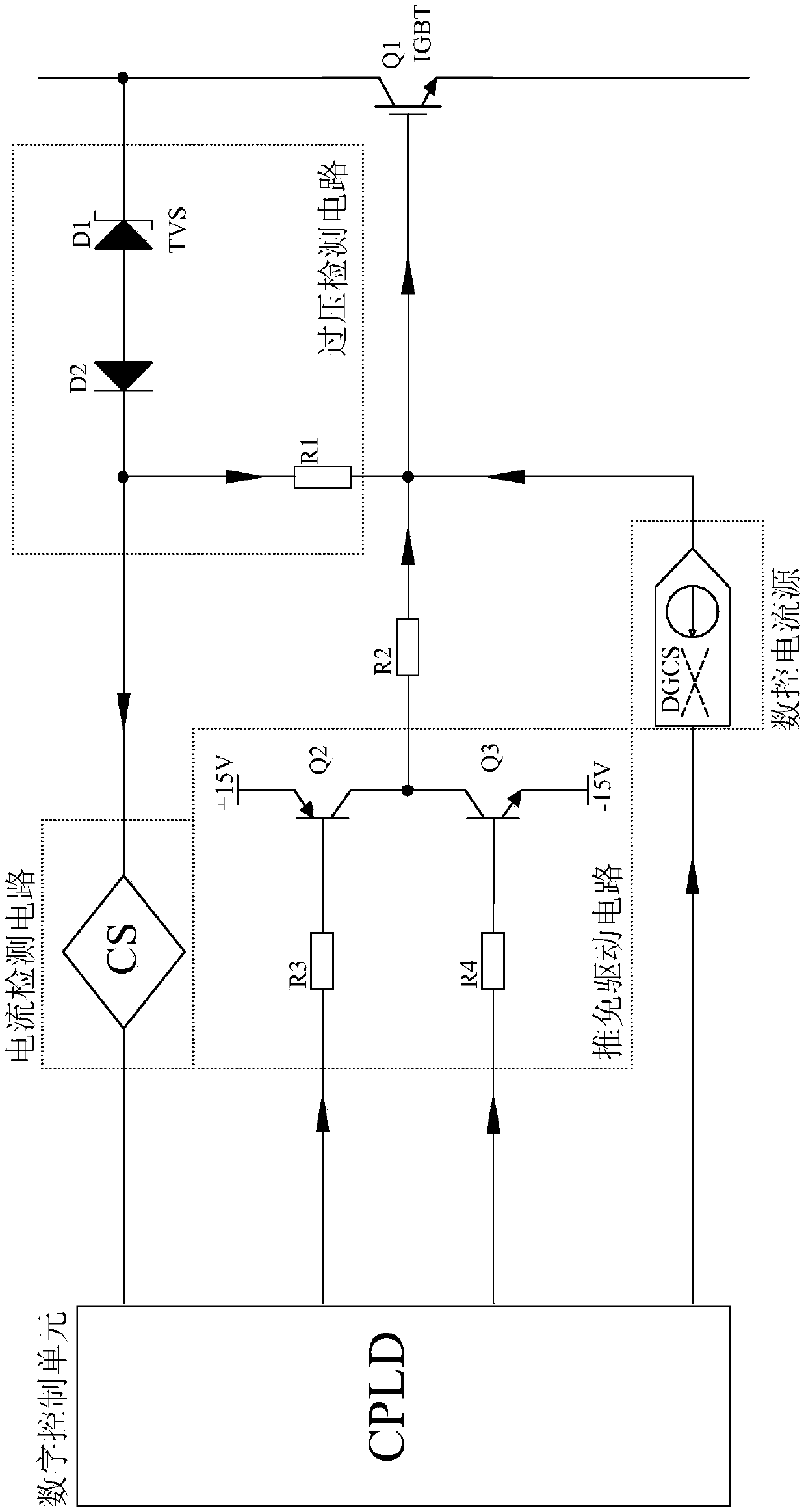

[0025] like figure 1 The digitally controlled active IGBT drive circuit shown includes a digital control unit, a push-pull drive circuit, an overvoltage detection circuit, a current detection circuit, a digitally controlled current source and an IGBT. The digital control unit is used to receive and calculate the signal sent by the current detection circuit, and send the control signal to the numerical control current source in combination with the PWM signal sent by the digital control unit to the push-pull circuit; the push-pull drive circuit is used to send the signal sent by the digital control unit The PWM signal is converted into an available drive signal for the IGBT; the overvoltage detection circuit is connected between the current detection circuit and the collector of the IGBT, the signal output end of the push-pull drive circuit is connected to the gate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com