Drum type spiral protection sleeve winding machine

A spiral protective sleeve, roller type technology, applied in pipeline protection, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of complex equipment structure, time-consuming and labor-intensive, large space occupation, etc., and achieve good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

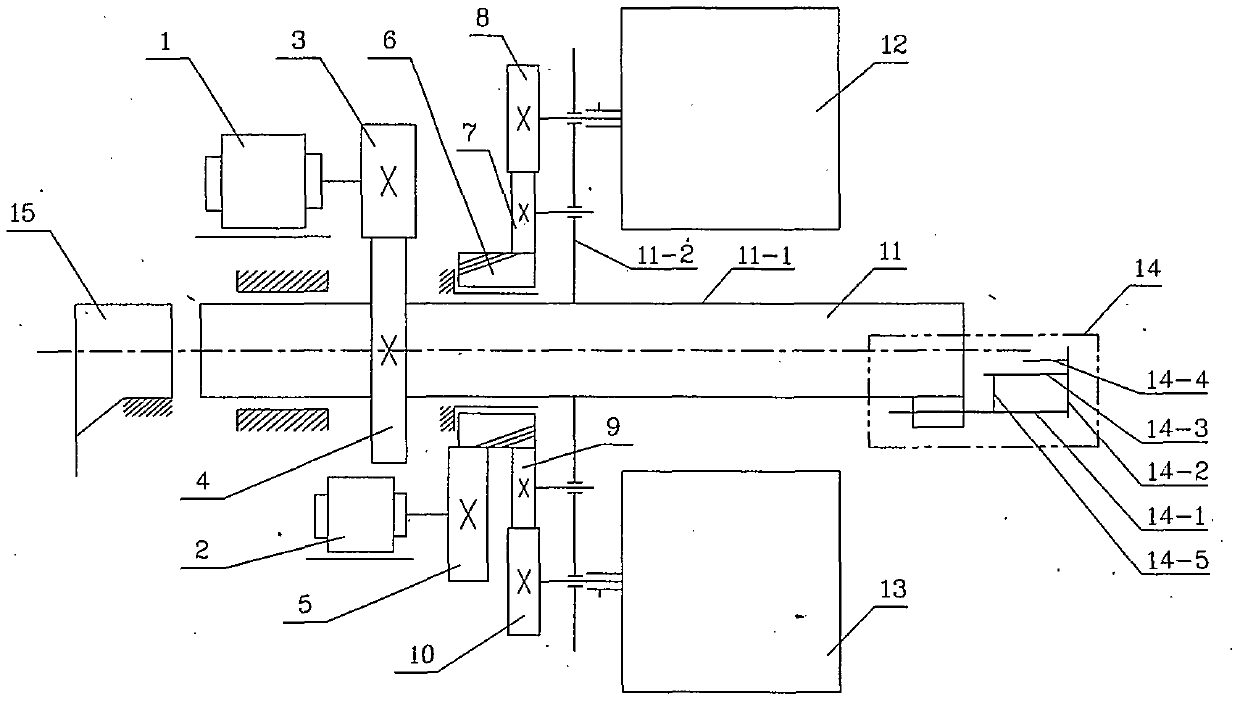

[0016] as attached figure 1 As shown, the main body of the present invention is a gear transmission mechanism made up of two sets of power units.

[0017] The reducer 1 drives the gear 3 to drive the gear 4 to rotate, so that the cylinder frame 11 assembled with the gear 4 rotates around the axis of the cylinder 11-1, and the gears 7, 8 and 9 installed on the cylinder frame 11, The gear 10, the drum 12, and the drum 13 rotate together. The power unit composed of reducer 1 is the power source for winding the spiral protective sleeve on the hose.

[0018] The reducer 2 drives the gear 5, drives the large ring gear 6, passes through the transition gears 7 and 9, drives the end gears 8 and 10, and the rollers 12 and 13 assembled with the end gears 8 and 10 rotate at a certain speed, the goal is to prevent The spiral boot twists into a twist and cannot be wound on to the industrial hose.

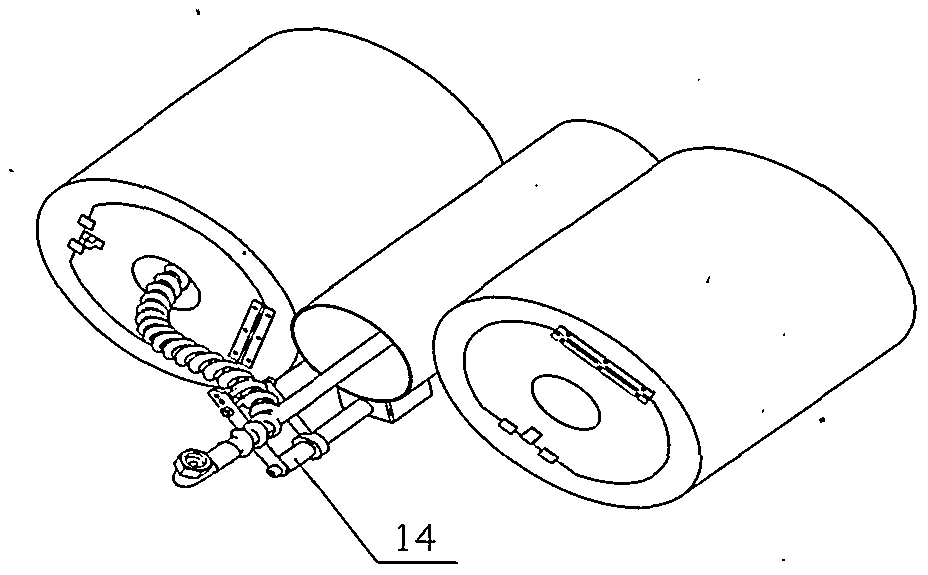

[0019] as attached figure 2 And attached image 3 As shown, the spiral protective sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com