Exhaust system heat shield for supercharged engine

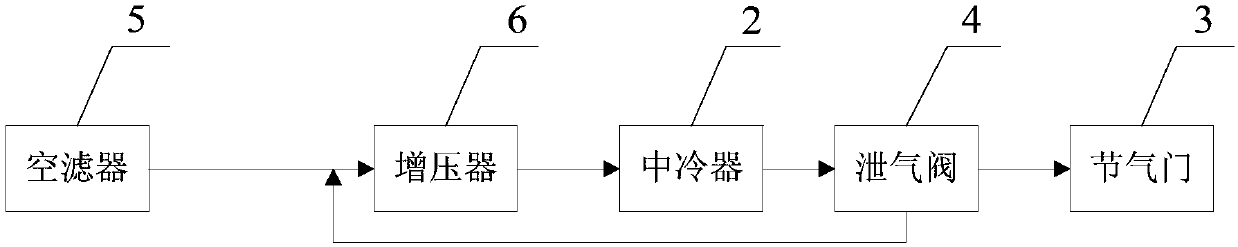

A supercharged engine and exhaust system technology, applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve the problem of large heat load of heat shield, low usage rate of cold air in supercharged, and ineffective isolation Problems such as high-temperature radiation of the engine, to achieve the effect of increasing the utilization rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

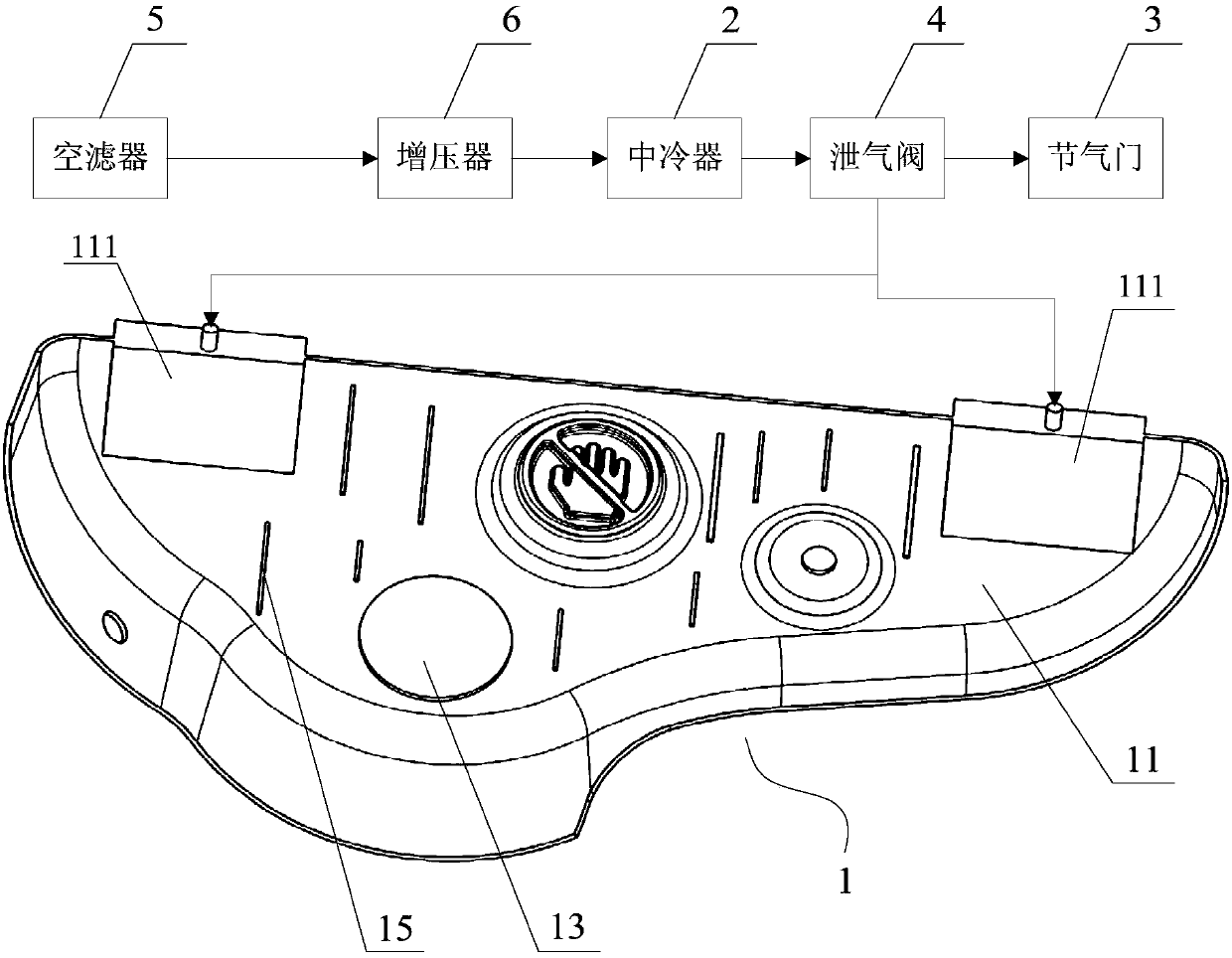

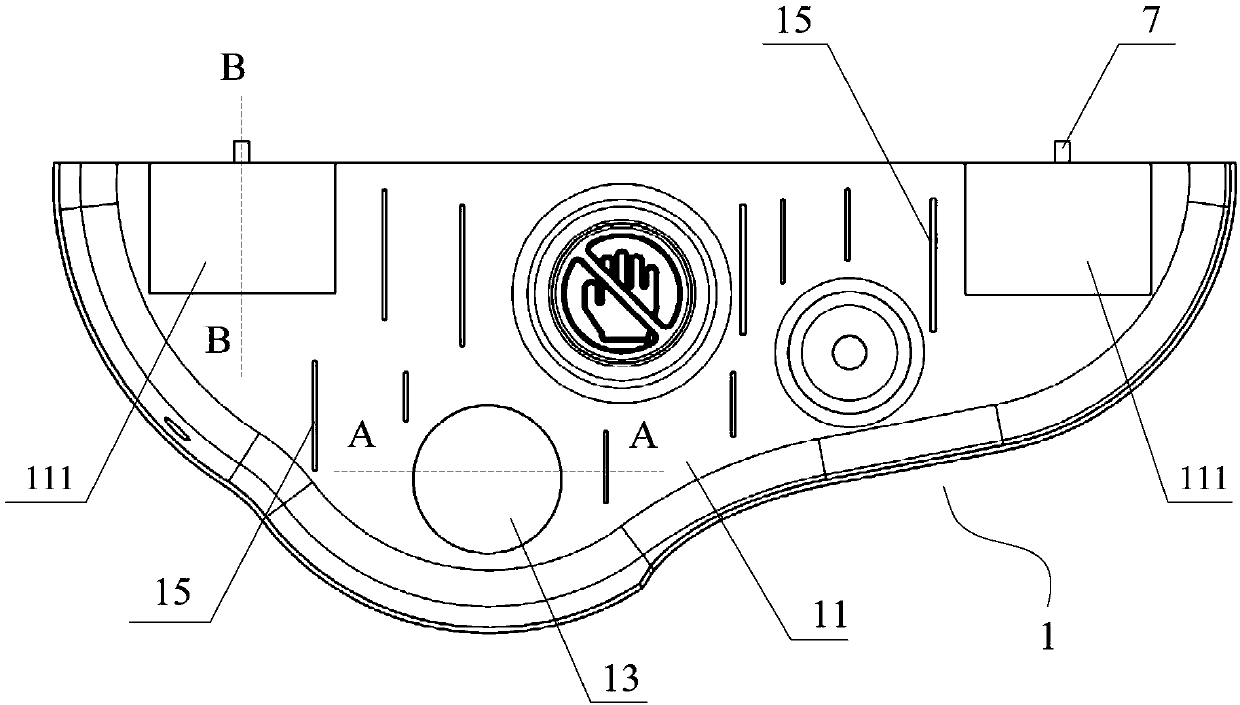

[0022] Such as Figure 2 to Figure 5 The heat shield of the exhaust system of the supercharged engine shown includes a heat shield body 1, and the heat shield body 1 is provided with a vent 13 for the hot air in the hot end area of the exhaust system to escape; the heat shield body 1 includes a first heat shield 11 close to the hot end of the exhaust system and a second heat shield 12 away from the hot end of the exhaust system. The left and right parts of the front side of the first heat shield 11 have a groove 111 respectively, The front left and right parts of the heat insulation board 12 respectively have a protrusion 121 corresponding to the groove 111, the edge of the first heat insulation board 11 is welded and sealed with the edge of the second heat insulation board 12, and an air flow cavity 14 is formed in the middle , the air storage cavity 10 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com