Pure cotton mercerization fabric and production process thereof

A production process, pure cotton fabric technology, applied in textile processing machine accessories, mercerizing of indefinite length fabrics, textiles and papermaking, etc., can solve problems such as uneven dyeing, improve uniformity, improve dyeing uniformity, reduce rework and cost-wasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

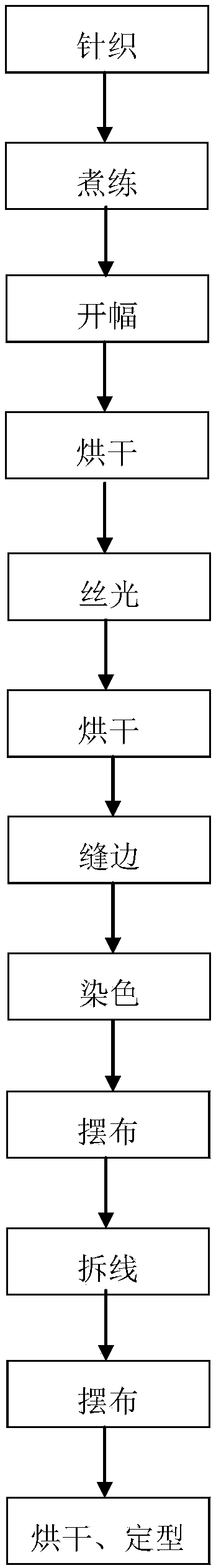

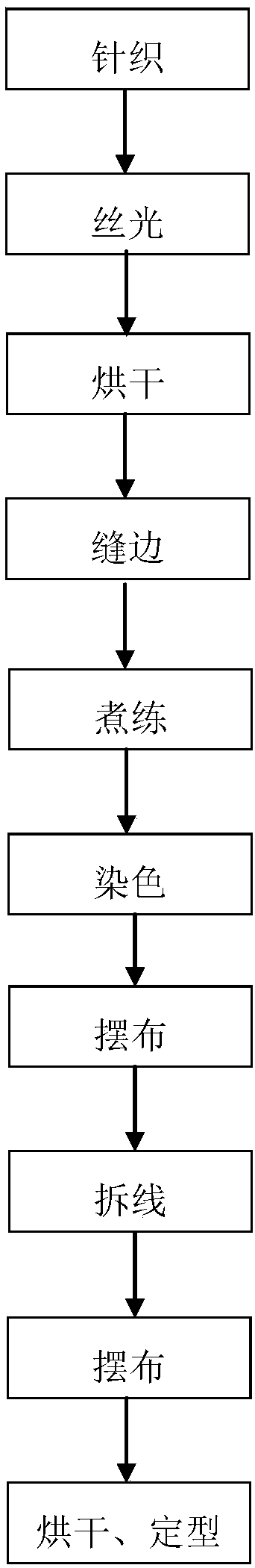

[0037] A kind of production technology of pure cotton mercerized fabric of the present embodiment comprises the following steps:

[0038] (1) Obtain pure cotton knitted fabric: weave pure cotton yarn on a circular knitting machine according to conventional methods, and obtain pure cotton knitted fabric after weaving is completed.

[0039] (2) Scouring: After adding water to the dyeing vat (model: Brazzoli) to the required water level, add the pure cotton knitted fabric to the dyeing vat for scouring. At this time, the pure cotton knitted fabric runs in the form of a rope in the dyeing vat. The temperature of the dyeing vat starts to rise to 60°C, and at 60°C, add penetrant EPD-C 2g / L, defoamer JET 0.2g / L; after the pure cotton knitted fabric runs in the dyeing vat for 10 minutes, add caustic soda NaOH 4g / L ; Add oxidant H after another 10 minutes of operation 2 o 2 3.6g / L; After running for 10 minutes, the dyeing machine starts to heat up to 98°C, and runs for 45 minutes af...

Embodiment 2

[0051] A kind of production technology of pure cotton mercerized fabric of the present embodiment, its raw material and steps are similar to embodiment 1, difference is in step (2) scouring process:

[0052] The dyeing vat starts to heat up to 55°C, and at 55°C, add penetrant EPD-C 2g / L, defoamer JET 0.2g / L; after the pure cotton knitted fabric runs in the dyeing vat for 10 minutes, add caustic soda NaOH 4g / L ; Add oxidant H after another 10 minutes of operation 2 o 2 3.6g / L; After running for 10 minutes, the dyeing machine starts to heat up to 90°C, and runs for 50 minutes after the temperature rises to 90°C.

Embodiment 3

[0054] A kind of production technology of pure cotton mercerized fabric of the present embodiment, its raw material and steps are similar to embodiment 1, difference is in step (2) scouring process:

[0055] The temperature of the dyeing vat starts to rise to 65°C, and at 65°C, add penetrant EPD-C 2g / L, defoamer JET 0.2g / L; after the pure cotton knitted fabric runs in the dyeing vat for 10 minutes, add caustic soda NaOH 4g / L ; Add oxidant H after another 10 minutes of operation 2 o 2 3.6g / L; After running for 10 minutes, the dyeing machine starts to heat up to 110°C, and runs for 40 minutes after the temperature rises to 110°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com