Photosensitive resin waste treatment method and photosensitive resin waste treatment system

A photosensitive resin and waste treatment technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as improper treatment of photosensitive resin waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

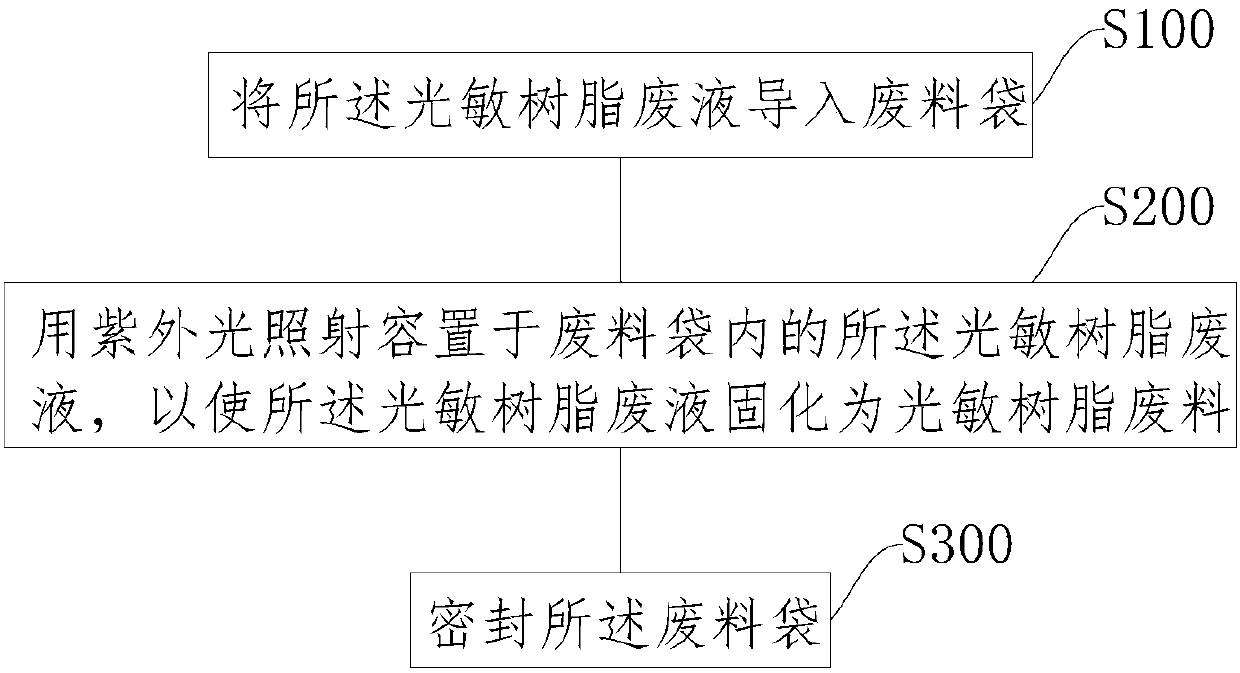

[0033] see figure 1 and figure 2 , this embodiment provides a photosensitive resin waste treatment method for treating the photosensitive resin waste liquid discharged from the photosensitive resin molding system 10. The photosensitive resin waste liquid is usually composed of oligomers, photoinitiators and diluents, etc. of harmful substances. The photosensitive resin waste treatment method provided in this embodiment can effectively treat the photosensitive resin waste liquid, solve the problem of improper treatment of the photosensitive resin waste liquid, and has the characteristics of being more environmentally friendly.

[0034] It should be noted that the photosensitive resin waste treatment method provided in this embodiment is implemented using the photosensitive resin waste treatment system 100. Before introducing the photosensitive resin waste treatment method provided in this embodiment, the photosensitive resin waste treatment system 100 is first Introduction a...

no. 2 example

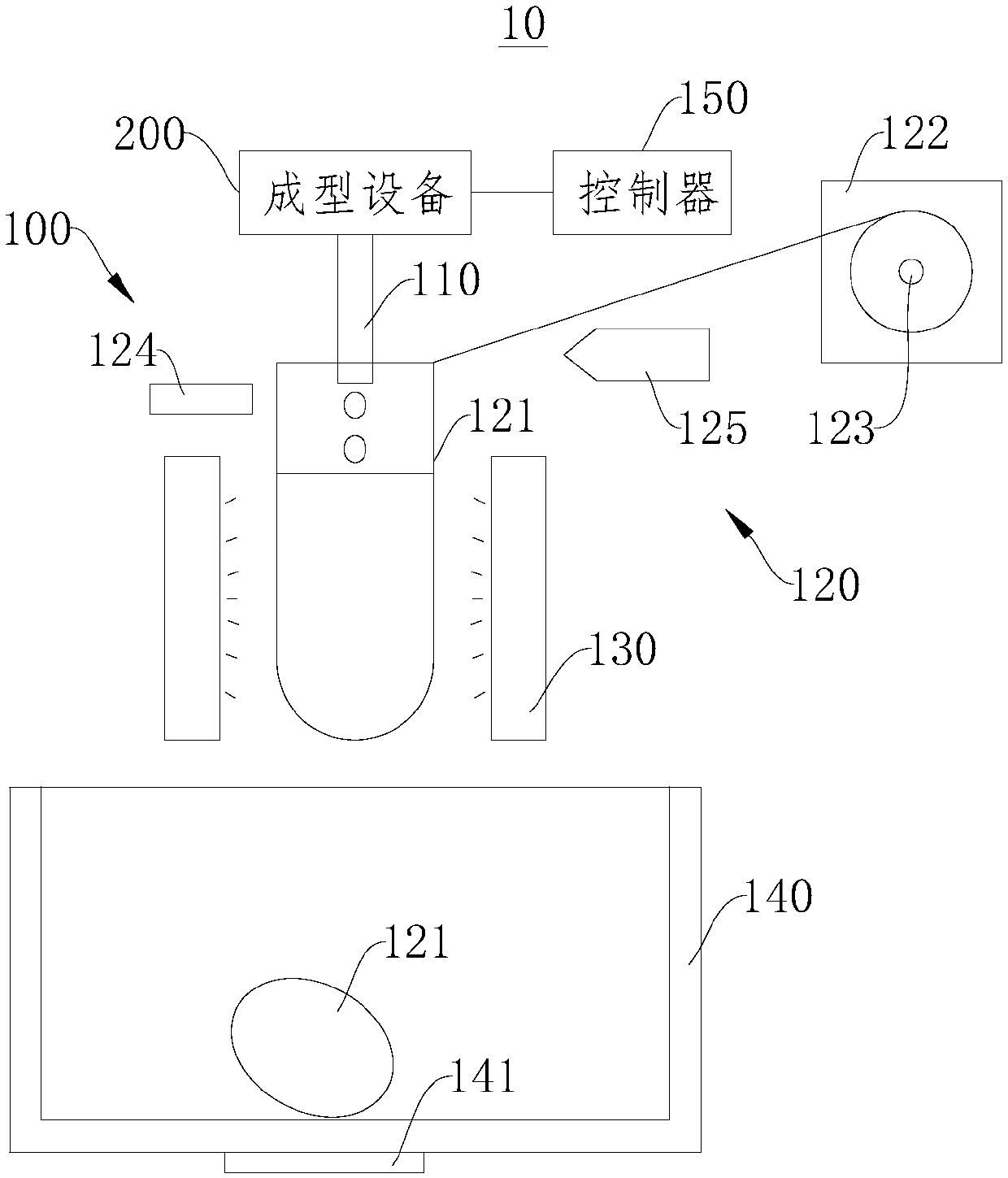

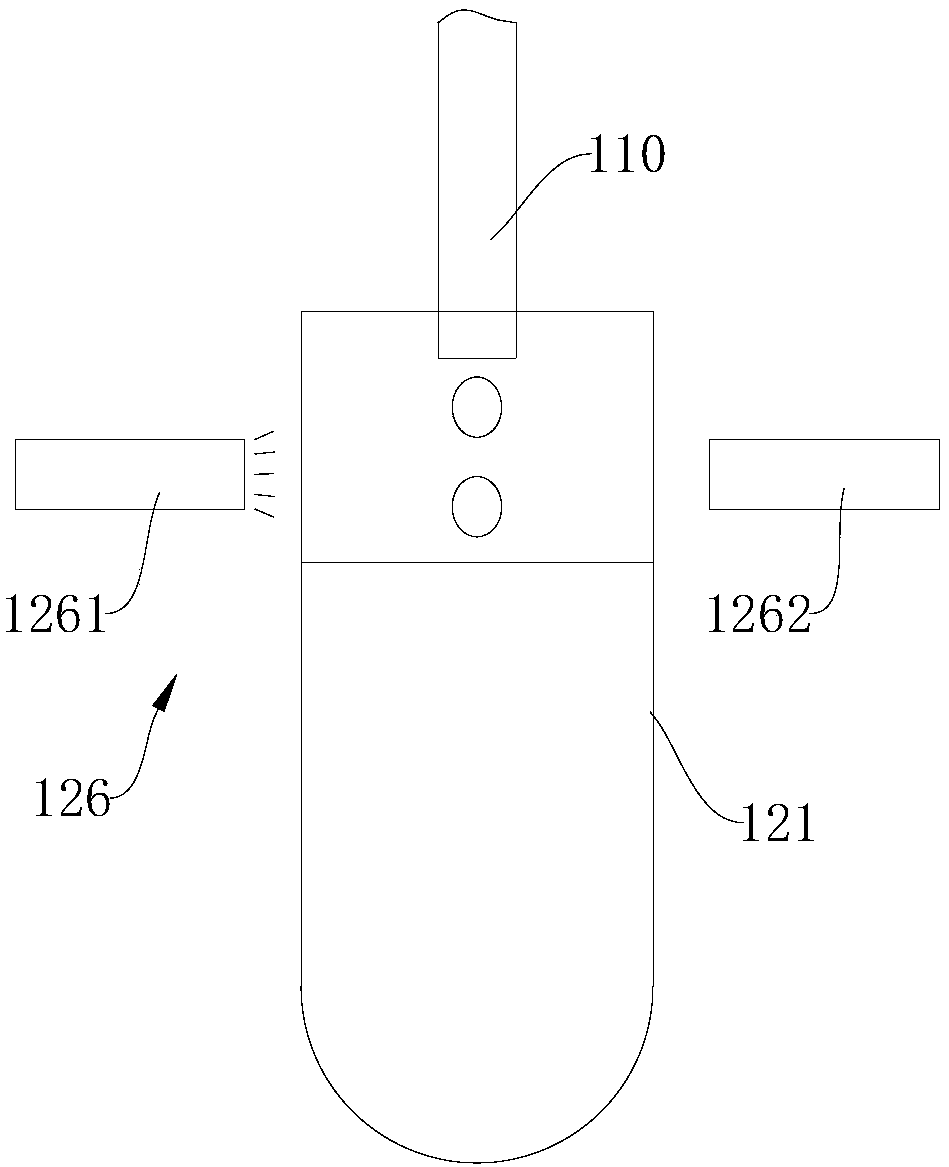

[0078] see Figure 1 to Figure 3 , this embodiment provides a photosensitive resin waste treatment system 100 for implementing a photosensitive resin waste treatment method. The photosensitive resin molding system 10 includes a molding device 200, the photosensitive resin waste treatment system 100 includes a flow guiding part 110, a collecting assembly 120 and a curing assembly 130, the collecting assembly 120 includes a waste bag 121 and a sealing member; the waste bag 121 is located at the bottom of the flow guiding part 110 One end, the other end of the flow guide part 110 is used to connect with the molding equipment 200; the seal is used to seal the waste bag 121 containing the photosensitive resin waste liquid; the curing component 130 is arranged around the collecting component 120, and the curing component 130 is used for The ultraviolet light is emitted to irradiate the photosensitive resin waste liquid in the collecting component 120 .

[0079] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com