Method for cleaning injectors of a direct-injection controlled-ignition engine

An engine, jet-type technology, applied in the direction of cleaning methods using liquids, testing of engines, cleaning methods and appliances, etc., can solve problems such as pollution, deterioration, torque loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

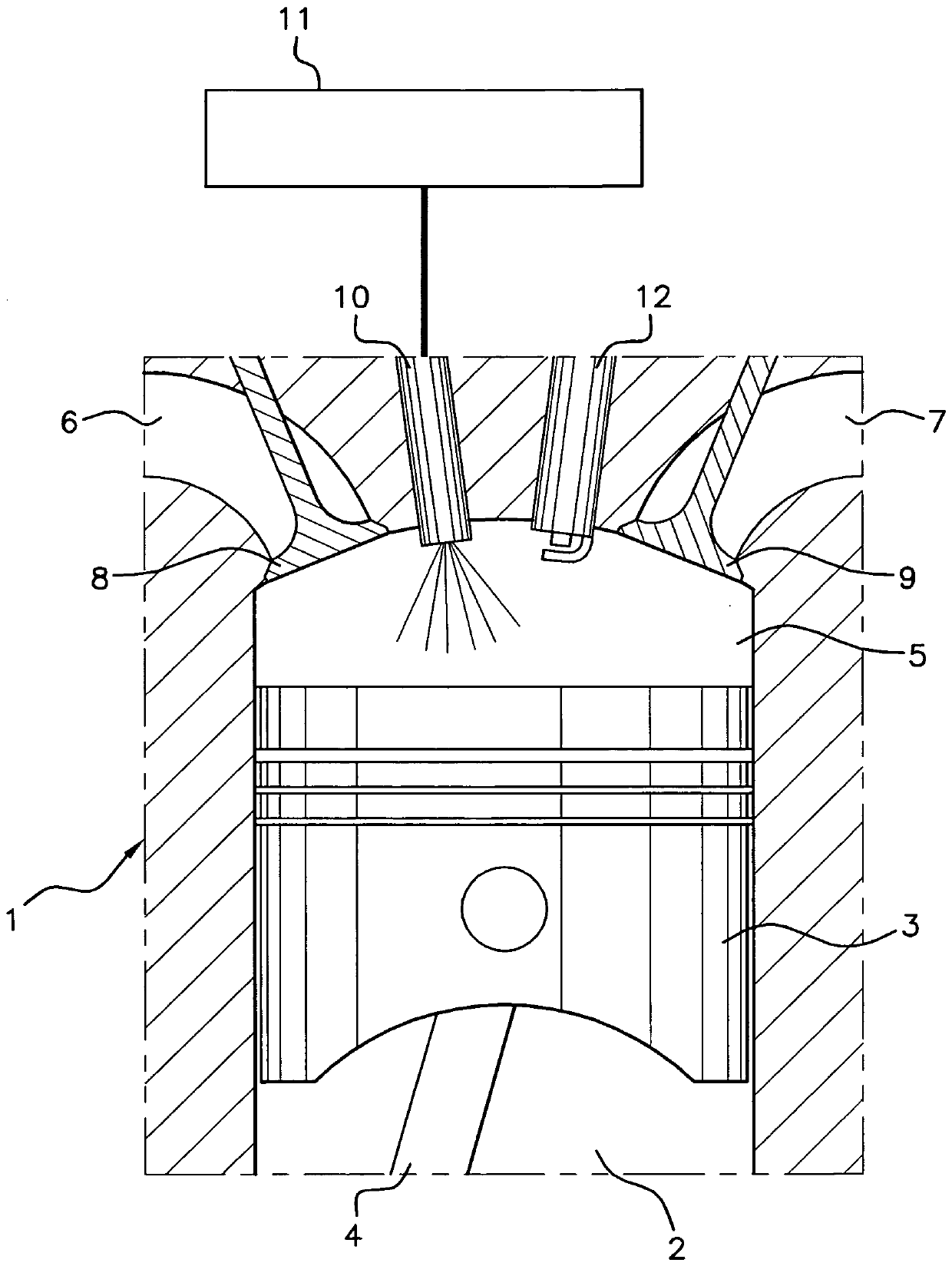

[0033] Such as figure 1 As shown, the method according to the invention aims at providing a method of cleaning the injectors of a direct injection controlled ignition engine 1 , which method may be preventive or remedial.

[0034] According to the figure 1 , a direct injection controlled ignition engine 1 is shown in the form of a single cylinder 2 housing a piston 3 actuating a connecting rod 4 and delimiting a combustion chamber 5 inside said cylinder.

[0035] This engine 1 also includes:

[0036] • inlet valve 8 on air inlet line 6,

[0037] • discharge valve 9 on discharge line 7,

[0038] • the injector 10, positioned to inject fuel directly into the combustion chamber 5, is controlled by the vehicle's engine control unit 11, programmed so as to determine the injection pressure PF and the injection time ti during each cycle,

[0039] • and spark plug 12 .

[0040] The object of the invention is to allow cleaning of the injectors 10 of the engine 1 as a preventive or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com