Fixture for injecting glue into and preheating ceramic core

A ceramic ferrule and fixture technology, which is applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of not being able to fix the ceramic ferrule and not being firm enough, and achieve the effects of convenient operation, improved work efficiency, and solid reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

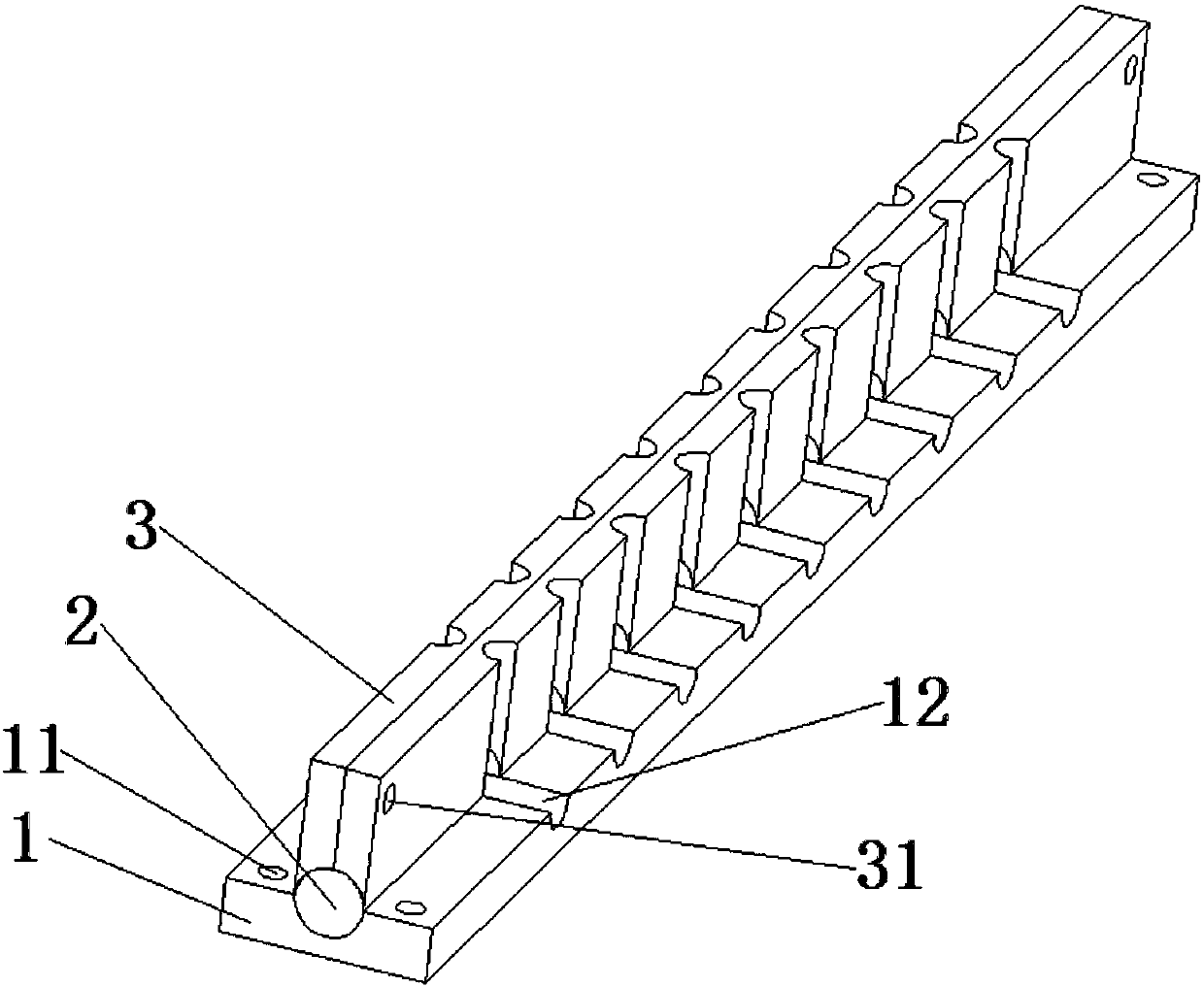

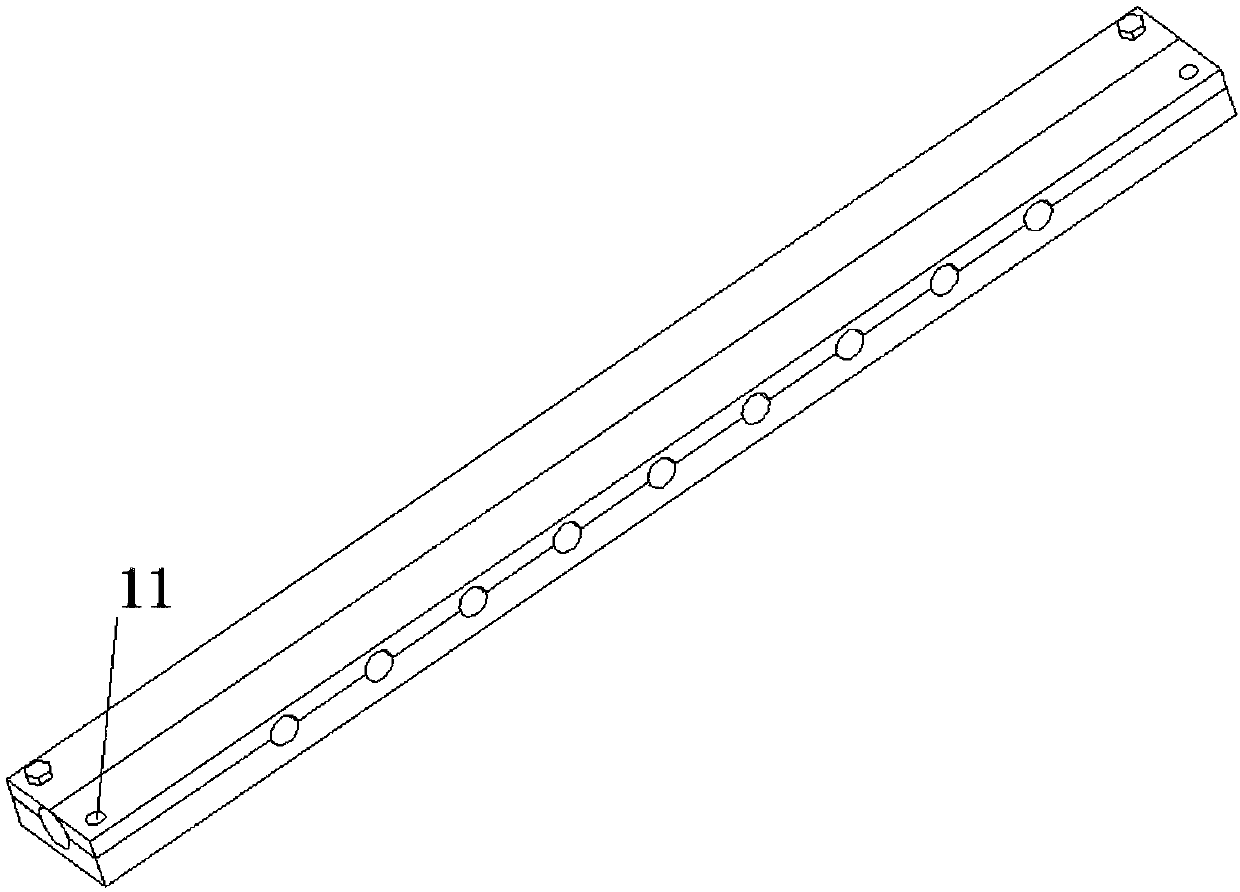

Embodiment 1

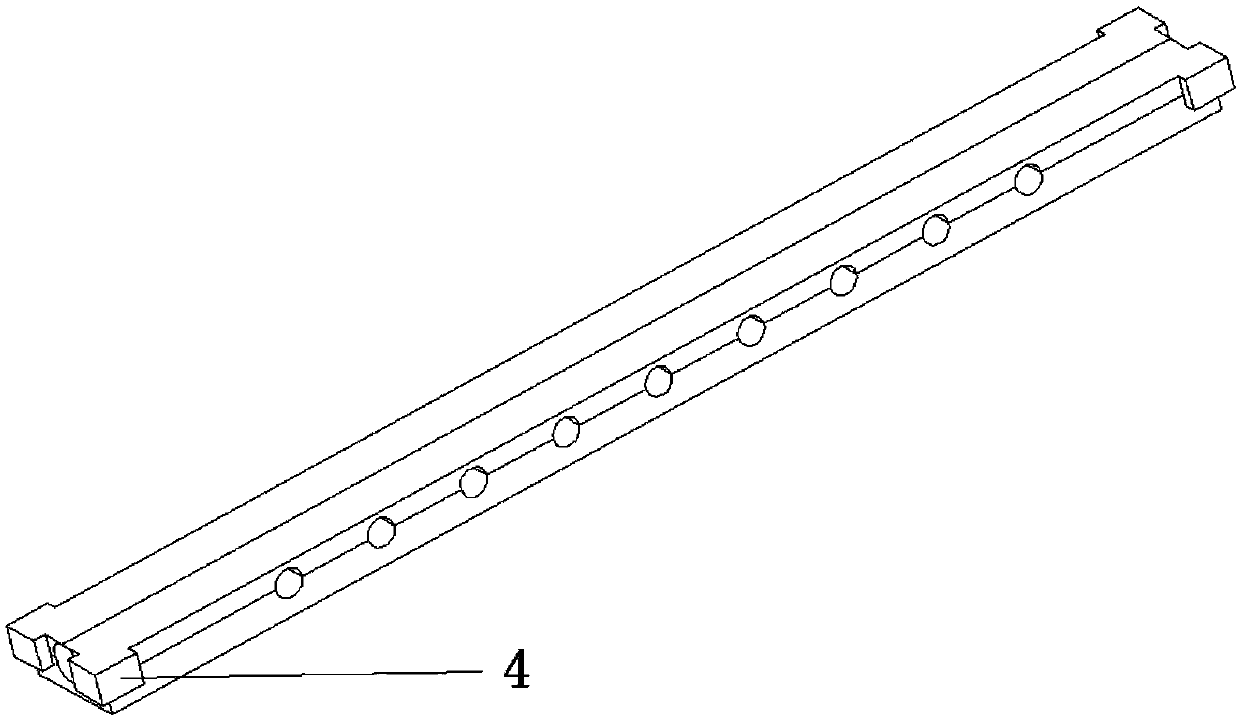

[0027] As above-mentioned fixture, present embodiment differs from it in that, refer to image 3 As shown, it is a schematic structural diagram of Embodiment 1 of the fixture for ceramic ferrule injection and preheating according to the present invention; the four corners of the pressure plate 3 contain a pinch plate 4, and the pinch plate 4 is connected to the The pressing plates 3 on both sides are connected. When the ceramic ferrule is preheated, it is only necessary to put down the pressing plate 3, and the pressing plate 3 and the base 1 are buckled together through the pinching plate 4, without It needs to be fixed by screws or bolts, and there is no need to punch mounting holes 11 on the base 1 and the pressure plate 3, which reduces the processing steps accordingly, makes it relatively easy to use, and improves work efficiency.

Embodiment 2

[0029] As above-mentioned fixture, present embodiment differs from it in that, refer to Figure 4 As shown, it is a schematic structural diagram of Embodiment 2 of the fixture for ceramic ferrule injection and preheating according to the present invention. The pressure plate 3 on the fixture becomes one-sided, that is to say, when the ceramic ferrule When injecting glue, it is not necessary to turn over and fix the pressing plate 3, and directly pass the ceramic ferrule into the fixture for glue injection. The fixture also includes a plurality of fixed locks 5, and the fixed lock The buckle 5 is installed on the base 1, and the position of the fixed lock 5 corresponds to the position of the groove 12, and is used to fix the ceramic ferrule inserted in the fixture to ensure the safety of the ceramic ferrule. flatness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com