Thermal conductivity detector and gas chromatograph

一种热传导率、检测器的技术,应用在仪器、测量装置、科学仪器等方向,能够解决测定灵敏度偏差、色谱图经时漂移等问题,达到时间分辨率提高、增长信号取得时间、实现灵敏度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

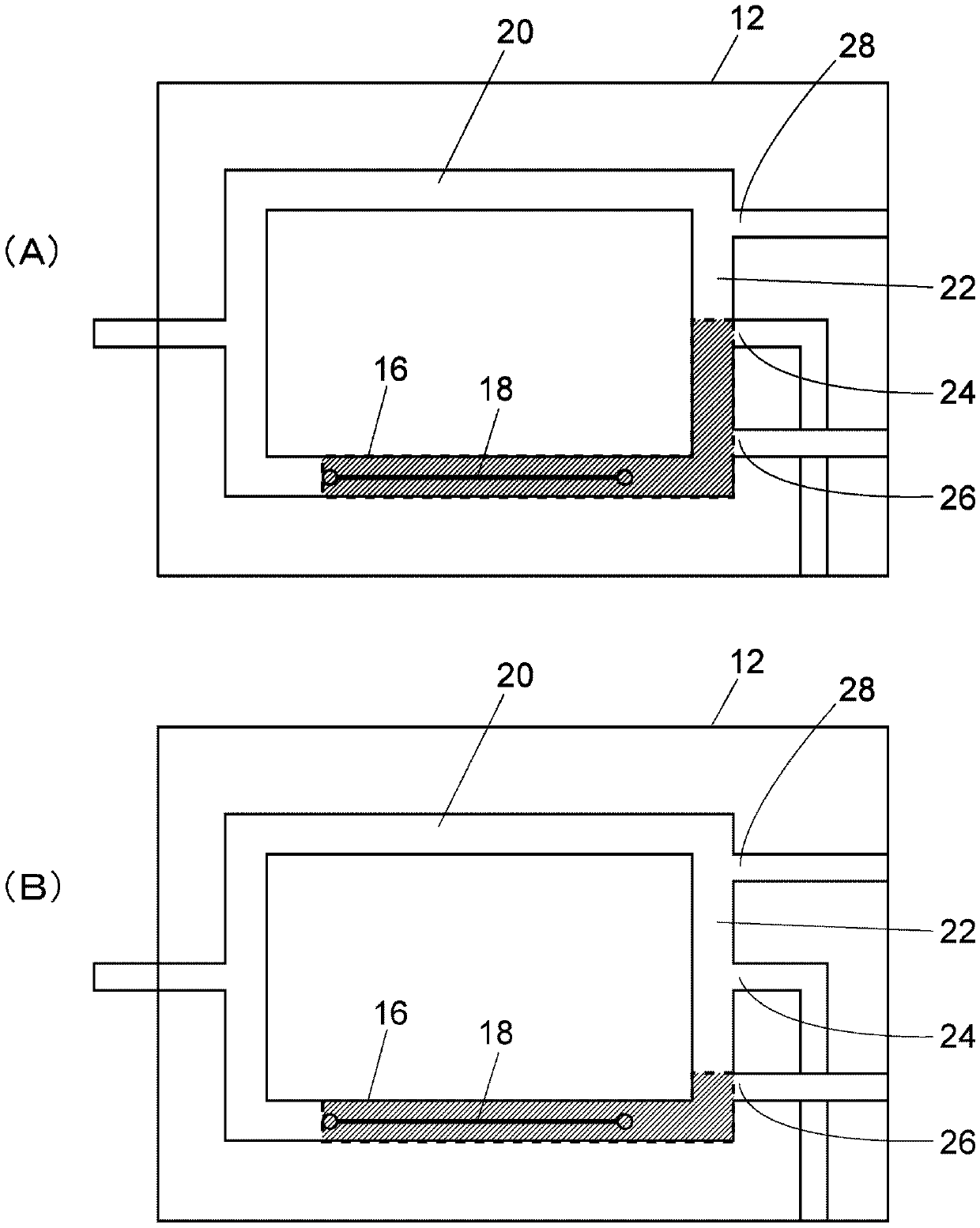

[0058] Hereinafter, an example of a thermal conductivity detector and a gas chromatograph including the thermal conductivity detector will be described with reference to the drawings.

[0059] First, use figure 1 A gas chromatograph of an example and a thermal conductivity detector used in the gas chromatograph will be described.

[0060] In the gas chromatograph, a sample vaporizer 4 is connected to one end of an analytical column 2 for separating a sample into components, and a detector 10 is connected to the other end of the analytical column 2 . The analytical column 2 is accommodated in the column heating furnace 8 and its temperature is adjusted. A syringe 6 is provided in the sample vaporization unit 4 , and the sample injected from the syringe 6 is vaporized in the sample vaporization unit 4 and guided to the analysis column 2 together with the carrier gas supplied to the sample vaporization unit 4 . The sample gas introduced into the analytical column 2 is separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com