Universal pneumatic fixture for visual inspection devices

A pneumatic fixture and angle technology, which is applied to measuring devices, instruments, measuring instrument components, etc., can solve the problems of long line change time, low work efficiency, and high cost of visual inspection devices, and achieve short line change time and low production cost. , the effect of reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

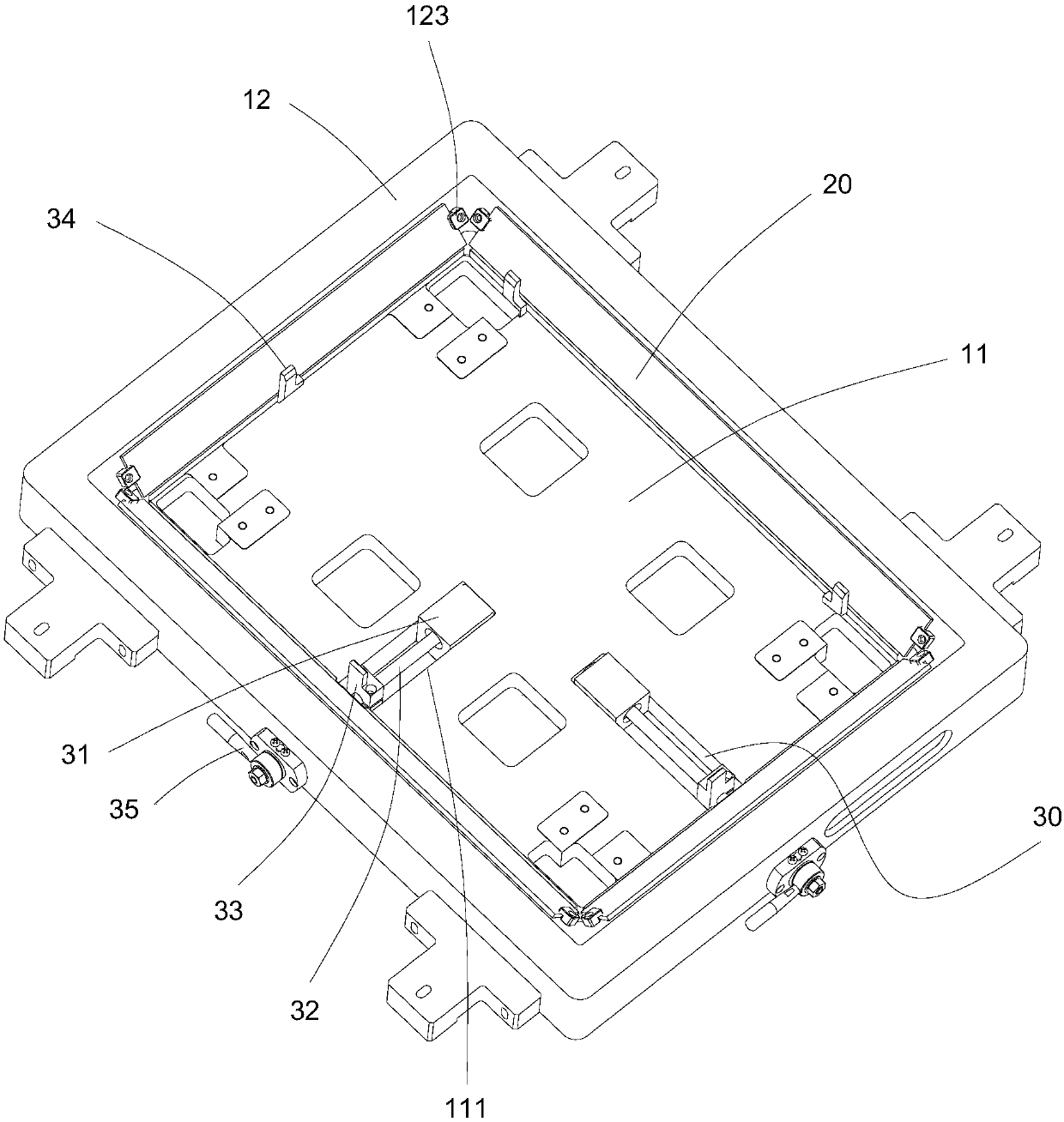

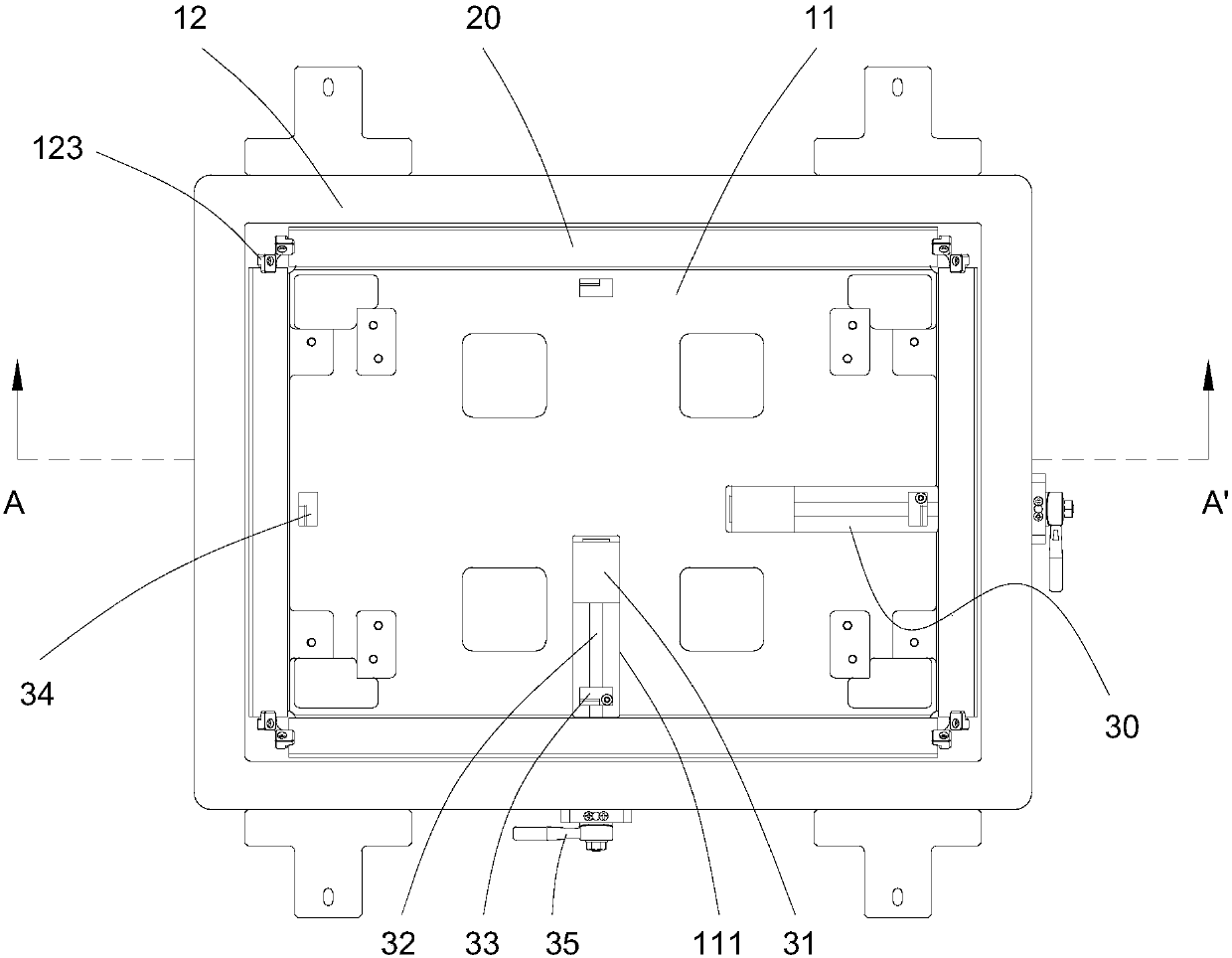

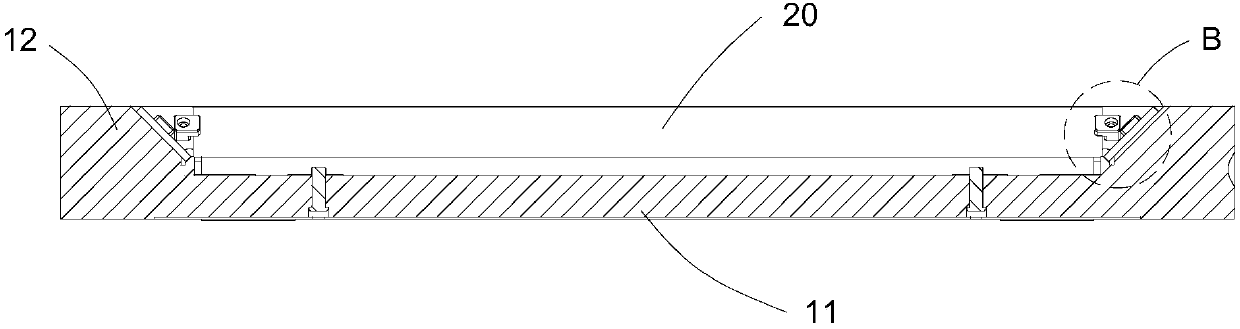

[0021] refer to Figure 1 to Figure 4 .

[0022] The invention discloses a general pneumatic clamp for a visual inspection device, comprising a bottom plate 11, a frame 12 is fixed around the bottom plate 11, the thickness of the frame 12 is greater than that of the bottom plate 11, that is, the highest position of the frame 12 is higher than the highest position of the bottom plate 11 High, around the inner side of the frame 12 is provided with a reflector 20, preferably, the reflector 20 is a total reflection mirror, the reflective surface of the reflector 20 is inclined above the center of the bottom plate 11, and the reflective surface of the reflector 20 forms an angle α with the horizontal plane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com