a waterproof cable

A technology for waterproof joints and casings, applied in the cable field, can solve the problems of poor waterproofness of cable joints, and achieve the effects of simple structure, convenient operation, and reduction of replacement and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

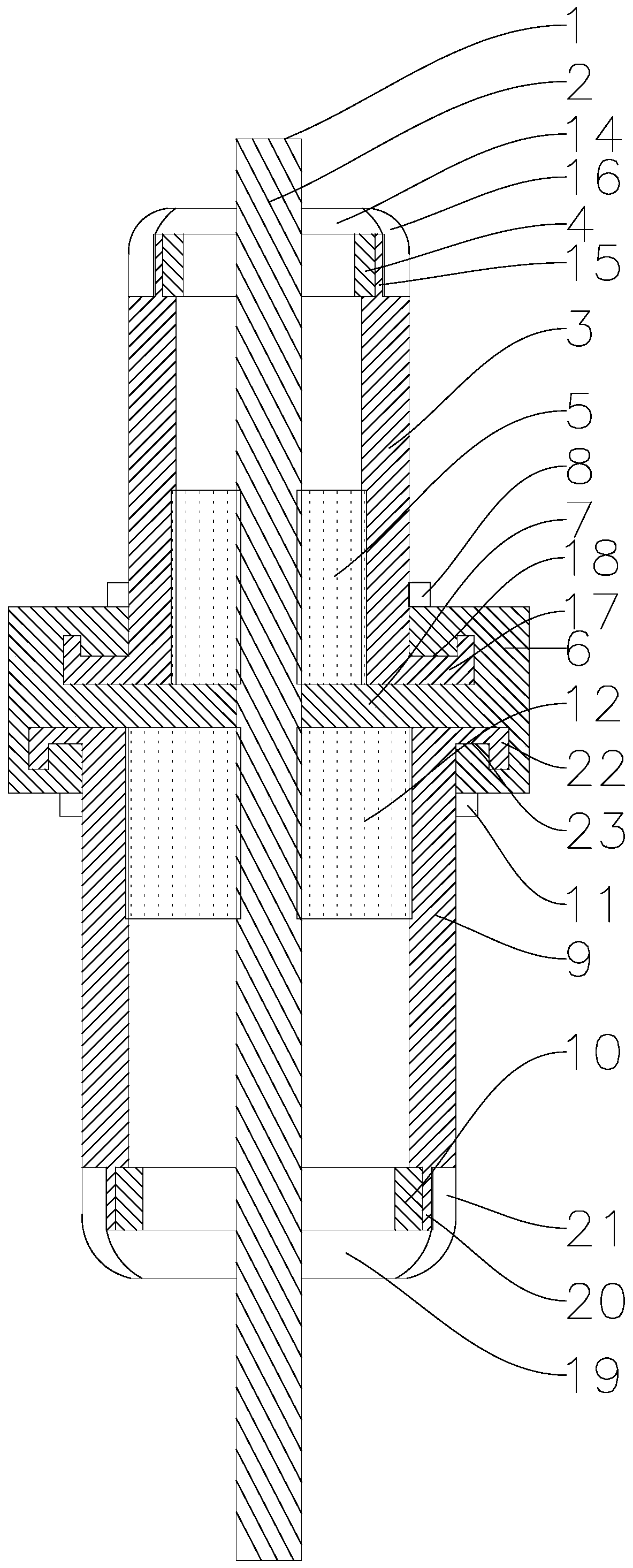

[0027] As shown in the figure, the present invention provides a waterproof cable, which includes a cable main body 1 and a waterproof joint connected to the outer periphery of the main cable main body 1. The main body 1 of the main cable is coated with several twisted wires 2. The waterproof joint includes:

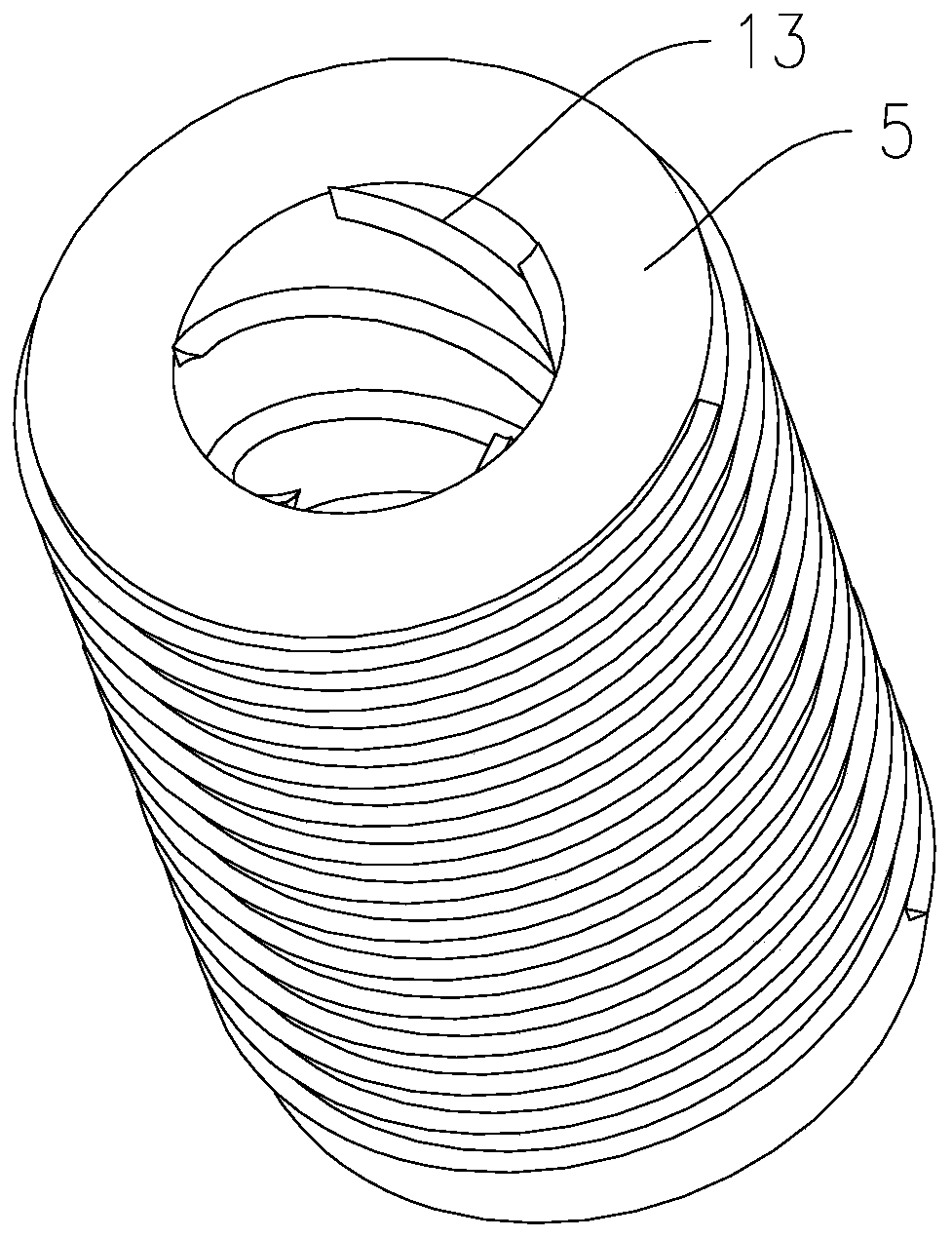

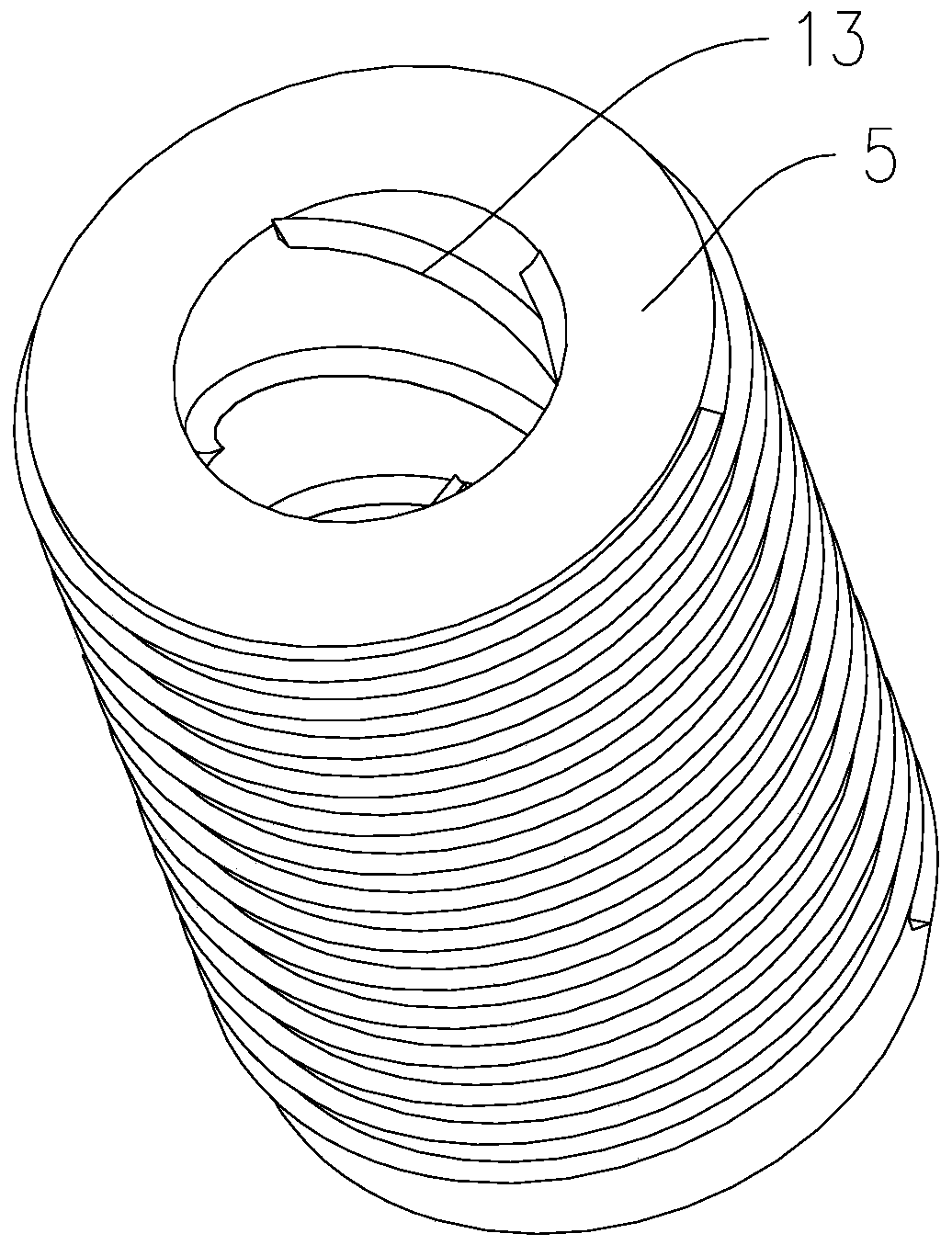

[0028] The upper casing 3, one end of the upper casing 3 is a plug-in end, the opening of the plug-in end is fixedly connected with an upper plug 4, and an upper sealing block 5 is arranged inside the upper casing 3, and the upper sealing block 5 and the inner wall of the upper casing 3 threaded connection,

[0029] Connect the sleeve 6, the inner wall of the connecting sleeve 6 extends axially with a stopper 7, the inner diameter of the stopper 7 is smaller than the inner diameter of the upper sleeve 3, the inner diameter of the stopper 7 is greater than or equal to the diameter of the cable main body 1, the upper sleeve The other end of 3 is rotatably connected to the c...

Embodiment 2

[0043] Such as image 3 As shown, other parts are the same as in Embodiment 1, except that the number of twisted wires 2 is 6, and the number of helical guide blocks 13 is 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com