Tensioning apparatus for scraper plate material delivering system, and scraper plate material delivering system and paving machine thereof

A technology of tensioning device and material conveying system, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of high machining accuracy, difficult disassembly and assembly of screws, and aggravated wear between the guide block chain and sprocket, so as to reduce the difficulty of processing and cost, alleviating longitudinal band segregation, and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

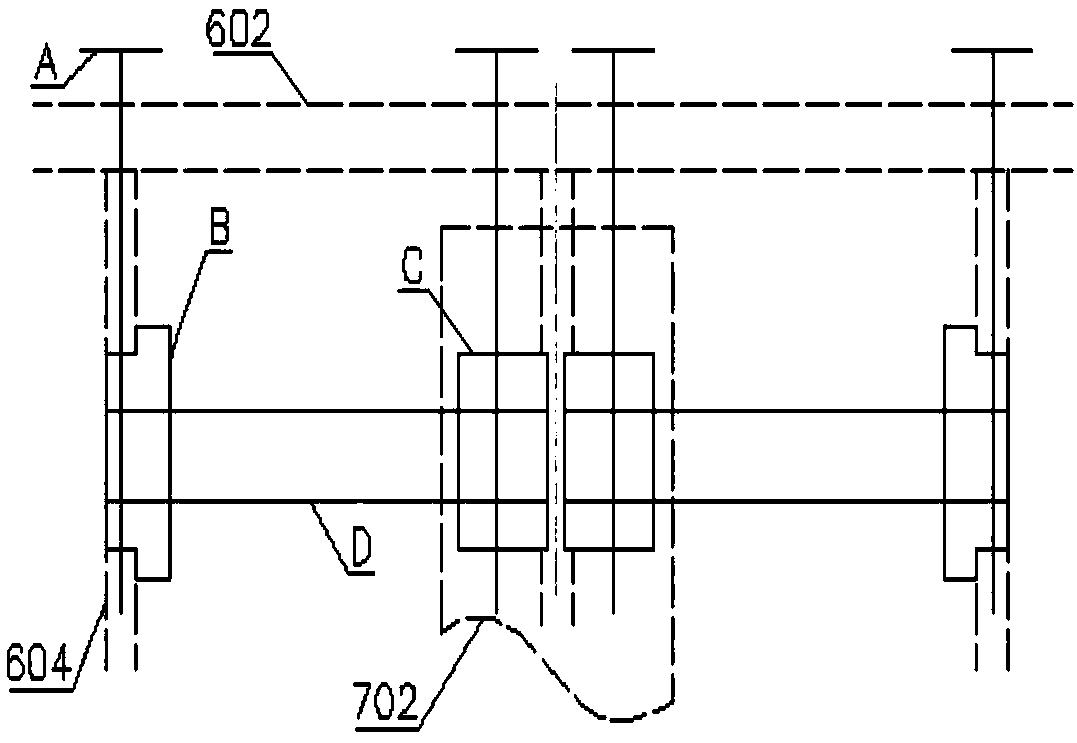

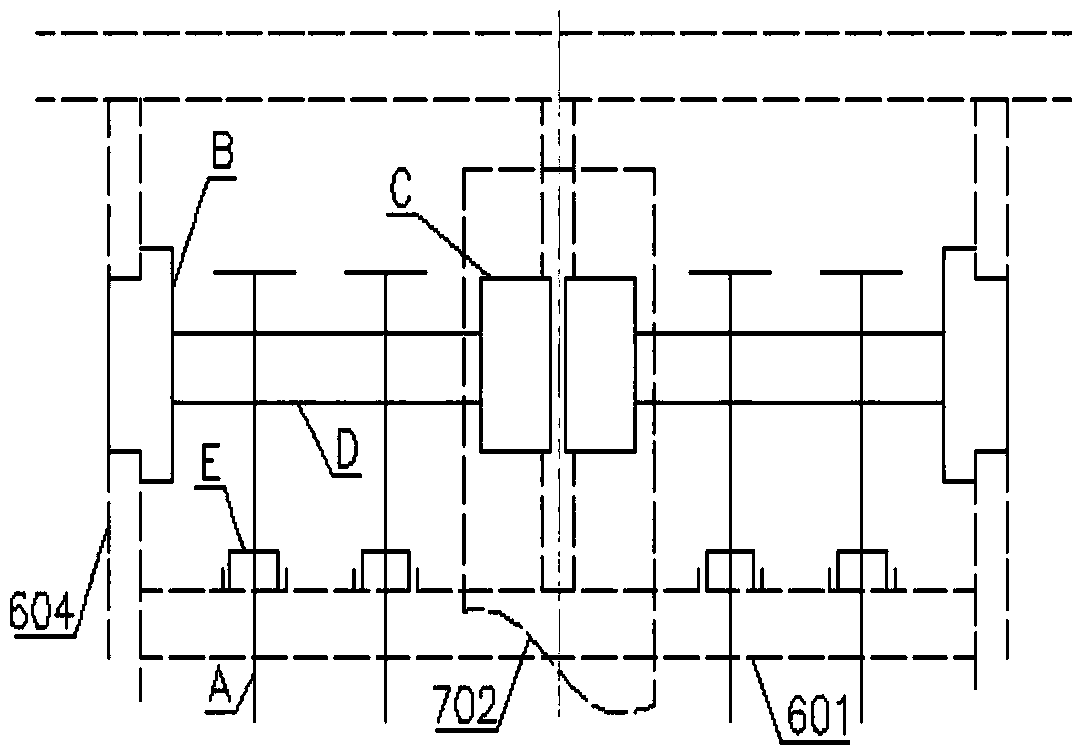

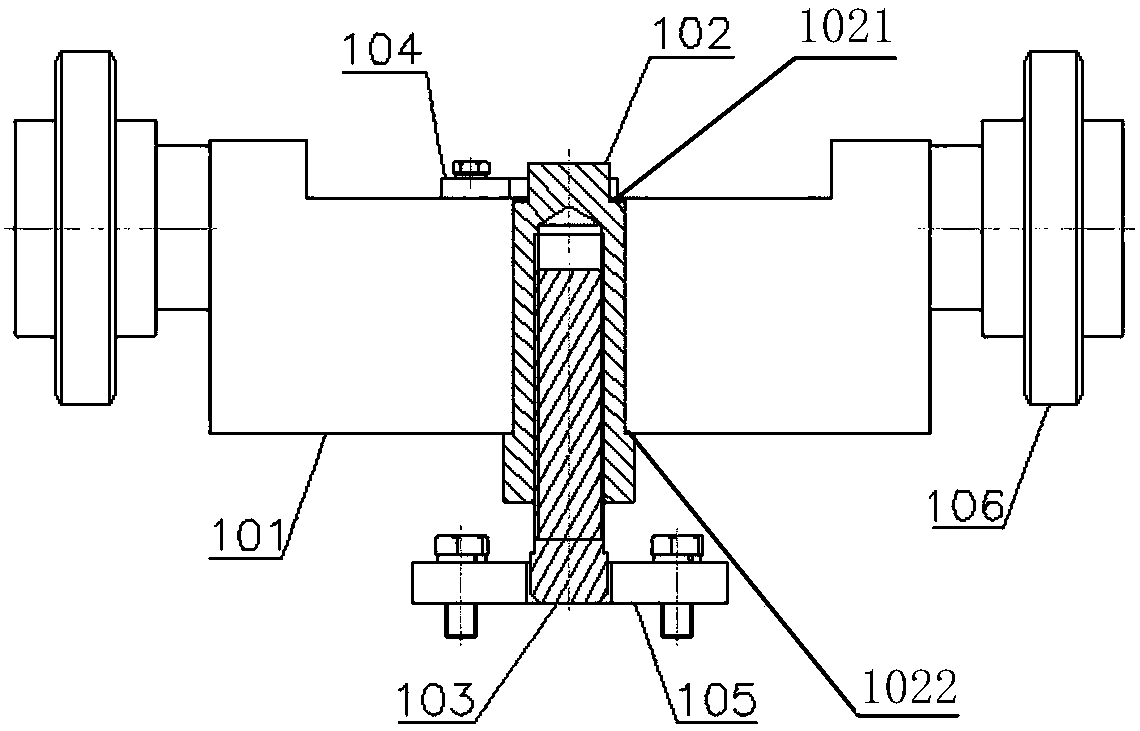

[0035] see Figure 3-5 As shown, a tensioning device for a scraper conveying system includes a guide support 101, a tensioning screw sleeve 102 arranged perpendicular to the length direction of the guide support, and a tensioning screw threaded with the tensioning screw sleeve. Screw rod 103, rotatably installed on the tension wheel 106 on both sides of the guide support, lock plate one 104, and lock plate two 105; the guide support 101 is slidably arranged on the frame support 603, so A guide slider 1001 is welded to the bottom of the guide support 101, and the guide slider 1001 is arranged symmetrically with respect to the center plane of the tensioning device. The tightening screw sleeve 102 is axially limited on the guide support 101 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com