Connection device for prefabricated floating slabs and construction method thereof

A connection device and construction method technology, applied in roads, tracks, buildings, etc., can solve the problems of shear hinge fixtures hindering the appearance and evacuation, difficult maintenance of shear hinges, space attitude errors, etc., to achieve compact structure, vibration isolation The effect is good, the effect of solving the attitude error and positioning problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

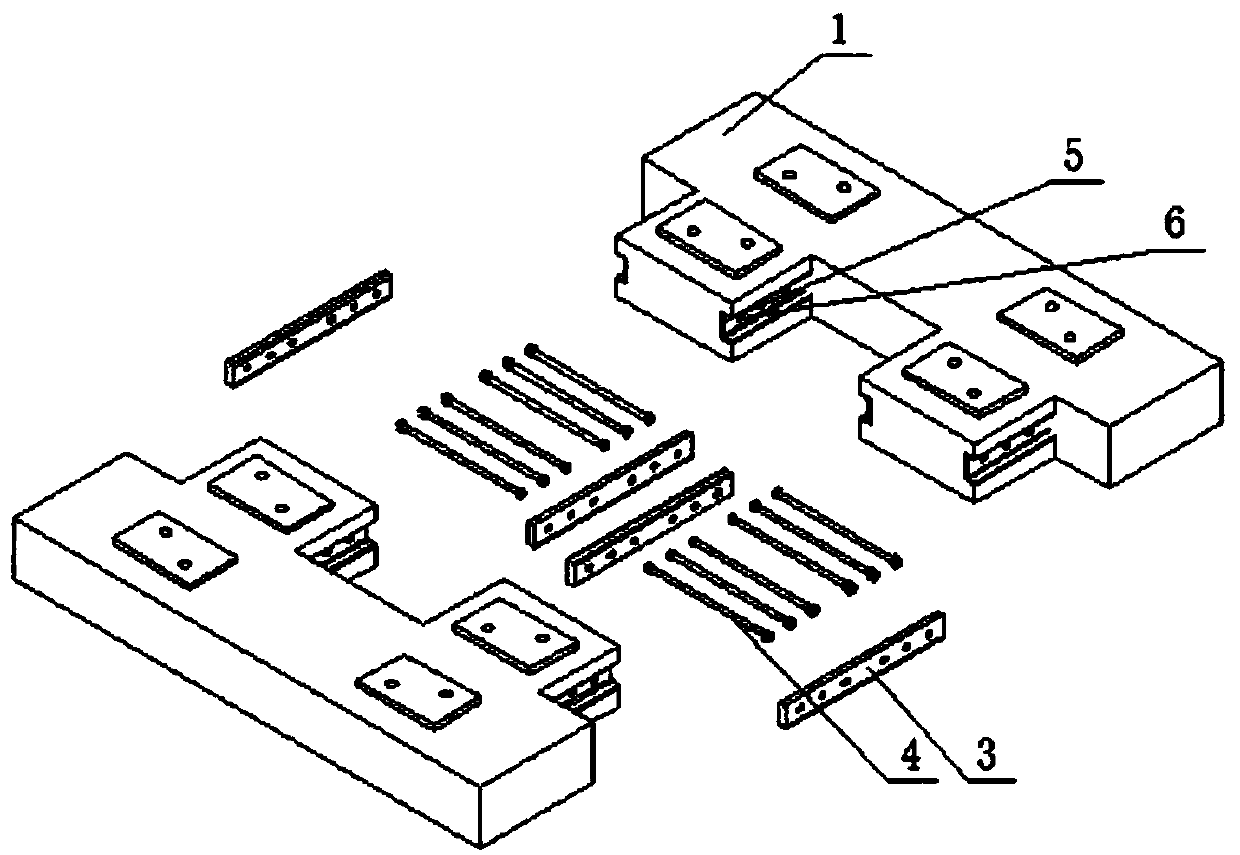

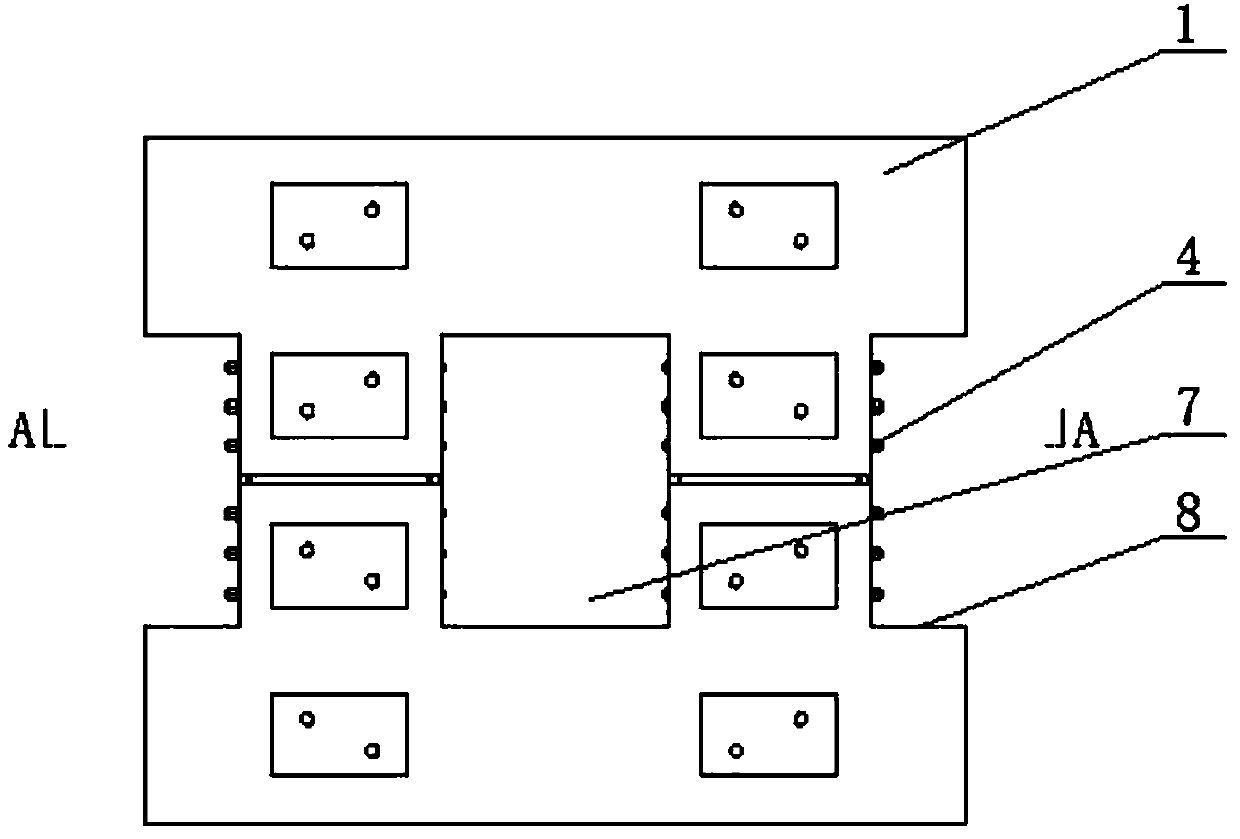

[0050] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the connecting device of the prefabricated floating slab in this embodiment includes the floating slabs 1 which are butted and installed to form a long track bed. The middle of the track bed formed by two adjacent floating slabs 1 is a square hole 7. The side waist is an opening 8; the two sides of the floating plate 1 are provided with grooves, and a channel steel 5 is installed in the groove, and a round hole 6 is opened on the channel steel 5, and a connecting piece 3 is installed inside the channel steel 5, and through the long Bolt 4 is locked.

[0051] Such as Figure 5 As shown, the structure of a single floating slab 1 is as follows: it includes a slab body, and one end of the slab body extends two concrete arms with a rectangular cross-section, so that two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com