Preparation method and application of self-supporting transition metal compound-based multilevel structure electrode material

A transition metal and electrode material technology, applied in the field of clean energy preparation, can solve the problems of high cost, poor stability and low activity of electrocatalysts, and achieve the effects of abundant reserves, controllable process, and accelerated mass transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

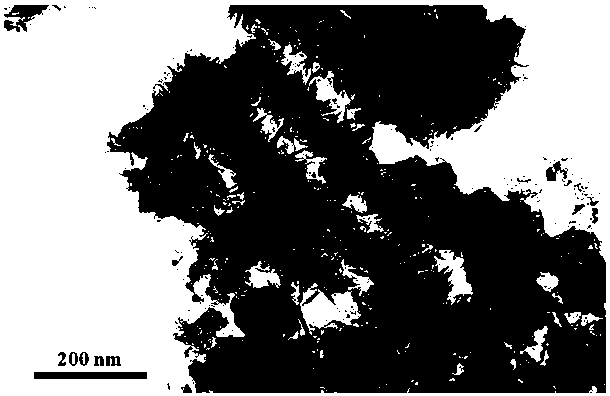

[0027] Embodiment 1: This embodiment describes a method for preparing a self-supporting transition metal compound-based multi-level structure electrode material, and the steps of the method are as follows:

[0028] Step 1: Mix 1 mmol divalent nickel salt, 2 mmol divalent cobalt salt and 1 g urea with 60 mL ultrapure water to form a clear pale pink solution, and stir for 20 min;

[0029] Step 2: Transfer the light pink solution obtained in Step 1 into a 100mL hydrothermal reactor 1, and then add a piece of carbon cloth with a length×width of (2~4)×(1~2) into the hydrothermal reactor 1, The hydrothermal reaction was carried out at a temperature of 100-120 °C for 4-10 h. After the reaction, the samples were washed with water and ethanol respectively, and the washing was repeated three times respectively to obtain NiCo 2 S 4 Precursors for nanoneedle arrays;

[0030] Step 3: NiCo obtained in Step 2 2 S 4 The precursor of the nanoneedle array was poured into NaS 2 aqueous solu...

specific Embodiment approach 2

[0032] Specific embodiment two: the preparation method of a self-supporting transition metal compound-based multi-level structure electrode material described in specific embodiment one, in step one, the divalent cobalt salt is Co(NO 3 ) 2 •6H 2 O. CoSO 4 •H 2 O, CoCl 2 •6H 2 O or Co(CH 3 COO) 2 • 4H 2 One of O, the divalent nickel salt is Ni (NO 3 ) 2 •6H 2 O, NiSO 4 •H 2 O, NiCl 2 •6H 2 O or Ni(CH 3 COO) 2 • 4H 2 One of O.

specific Embodiment approach 3

[0033] Specific embodiment 3: The preparation method of a self-supporting transition metal compound-based multi-level structure electrode material described in specific embodiment 1, in step 2, the reaction temperature is 120 ° C, and the reaction time is 6 h. This condition can make The obtained product has the best appearance and performance.

[0034] Embodiment 4: The preparation method of a self-supporting transition metal compound-based multi-level structure electrode material described in Embodiment 1, in step 3, the temperature of the hydrothermal reaction is 160 ° C, and the time is 6 h. Repeated experiments have proved that the process conditions are the best process conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com