Turbine blade coating preparation device with double-side crossed clamping structure

A clamping structure, turbine blade technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of high processing cost and low coating processing efficiency, and achieve easy processing and disassembly, The effect of increasing the amount of furnace loading and fewer accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

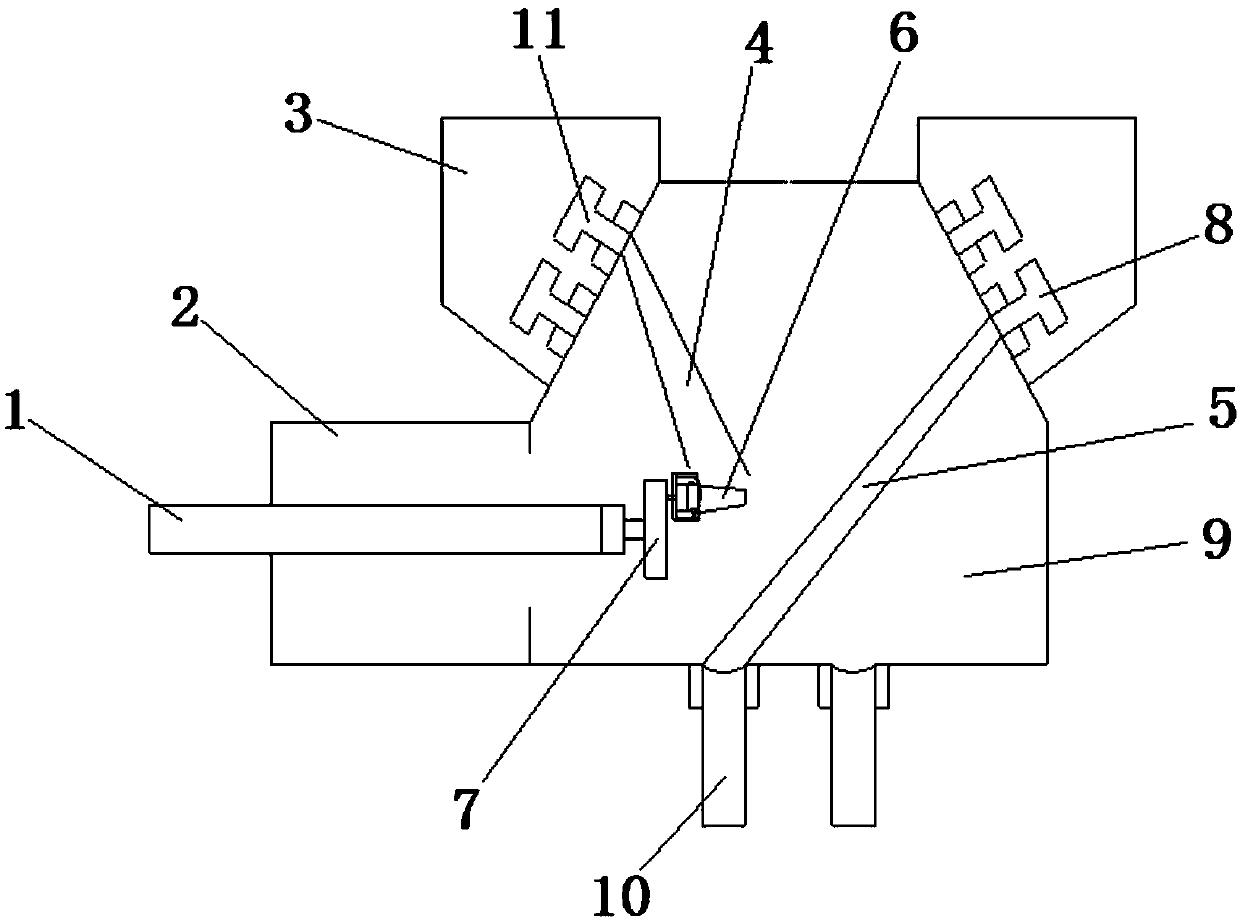

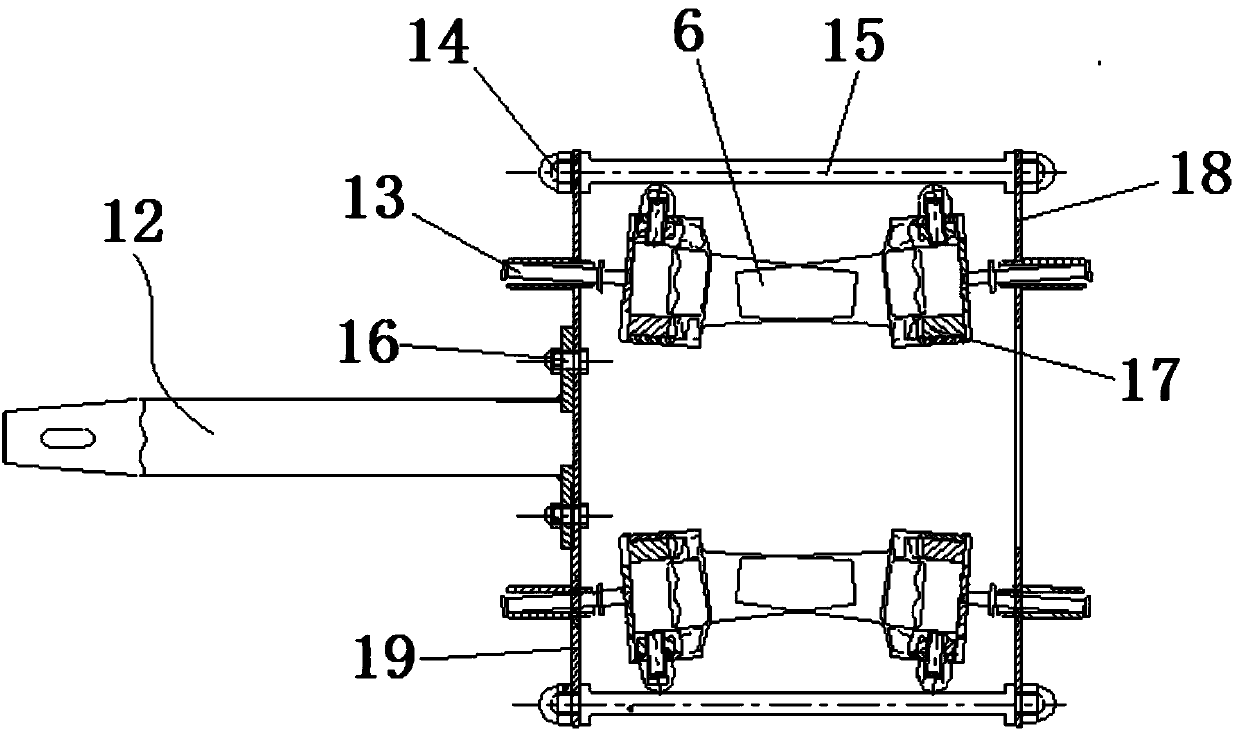

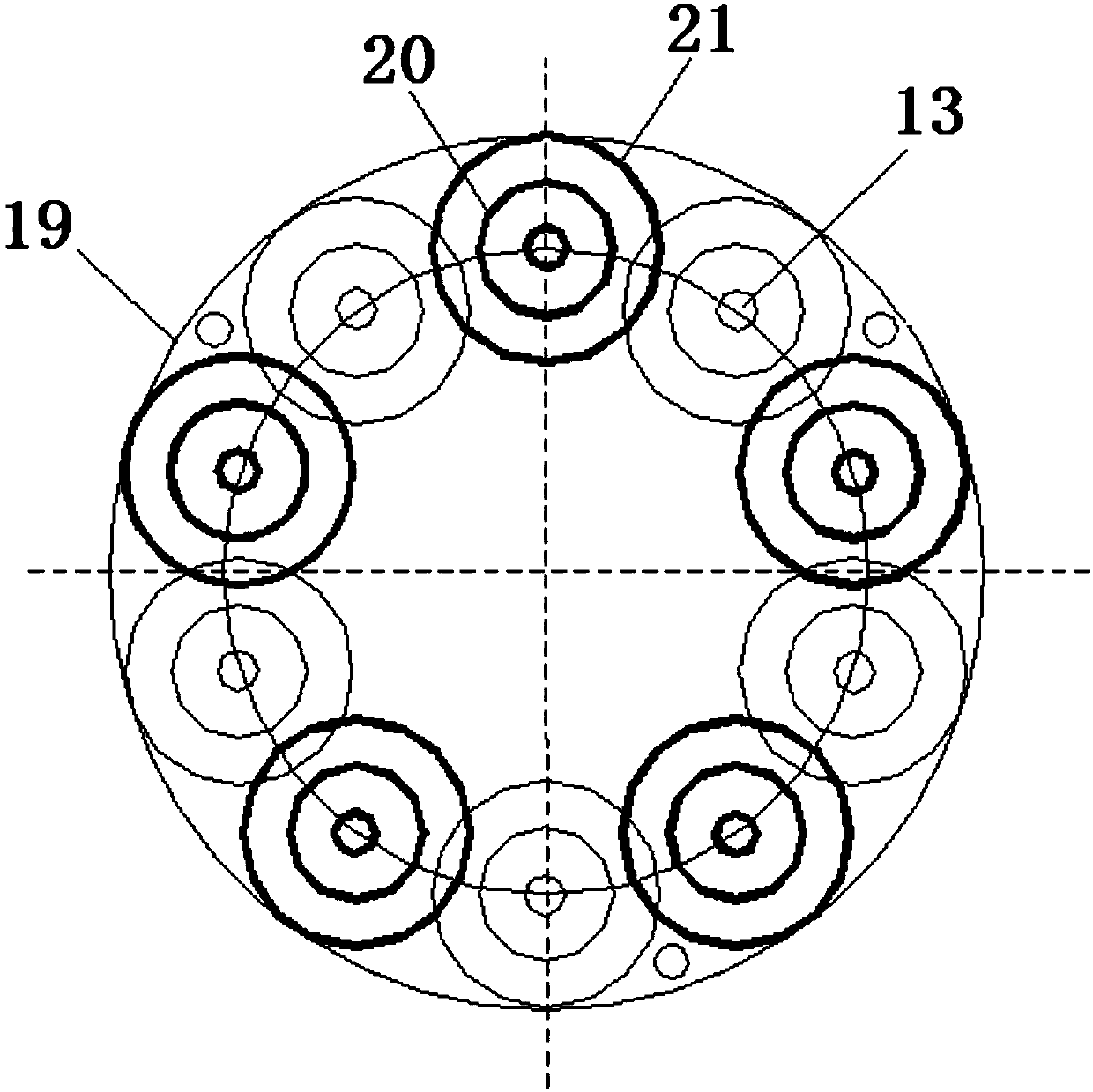

[0021] The invention provides a turbine blade coating preparation device with a double-sided cross clamping structure, such as figure 1 As shown, the loading chamber 2 is included, the precipitation chamber 9 communicates with the loading chamber 2, the loading chamber 2 is provided with a rotating shaft 1, the rotating shaft 1 is connected with a clamping device 7, and the clamping device 7 extends into the precipitation chamber 9 The top of the sedimentation chamber 9 is provided with two gun chambers 3, and the bottom of the sedimentation chamber 9 is provided with a plurality of material ingots 10, and the material ingots 10 are located directly below the blades clamped by the clamping device 7; wherein the left gun chamber 3 The first electron beam gun 11 is arranged inside, and the first electron beam gun 11 emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com