Inverted vacuum screw tightening device

A vacuum screw, inverted technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the gun nozzle cannot reach the tightening surface, affect the service life of the equipment, damage the electronic components, etc., to achieve simple structure and improved use. Longevity and effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

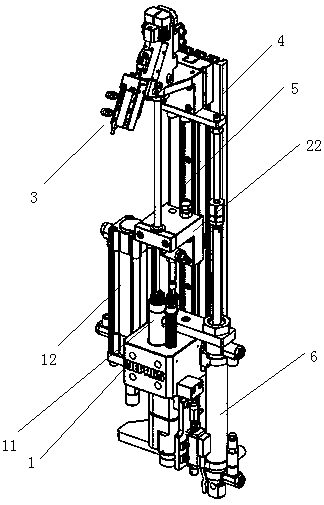

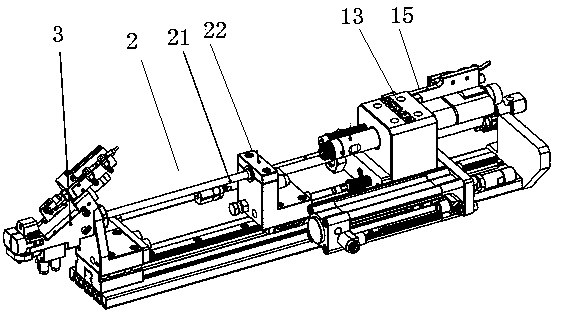

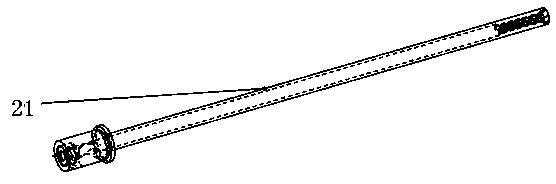

[0030] The invention discloses an inverted vacuum screw tightening device, such as figure 1 and figure 2 As shown, the tightening device includes a screwdriver assembly 1 connected from bottom to top based on a vertical support, a vacuum suction mechanism 2 and a gun nozzle 3, wherein the vertical support is provided with a back plate 4 with a vertical guide rail And the slide block 5 that slides on the guide rail. The gun nozzle 3 is arranged on the gun nozzle installation frame 300, and the top side of the gun nozzle 3 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com